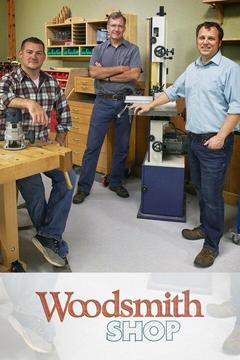

The Woodsmith Shop Live,Digital Talking Tape Measure Journal,Stanley Plane Blades Uk Online - How to DIY

Check out what's going on this week in the woodsmith shop! Shop Update Woodsmith live Turning a Cherry Platter. Woodsmith Live Rockler Woodworking and Hardware. Popular Woodworking. The Woodwright's Shop.

Woodsmith Plans. Stumpy Nubs Woodworking Journal. Woodworker's Journal Magazine. WoodWorkers Guild of America. Kreg Tool. Where's your hand? Man it's got things to do go good.

The woodsmith shop live everybody here we are back at Woods Smith for our Thursday update. We got uh quite a bit more to talk about today the woodsmith shop live I think one of the first things that we're gonna talk about is soon as I locate where mister Chris pitch went is he's been doing a little uh a little plumbing little open-heart surgery on our dust collection system, so I think we'll head over to the dust collector room and see what he's up to.

Chris Hello everyone Well, this is the heart of our gut collection system here at Seven-and-a-half Sparrow on nine cyclone the woodsmith shop live works fantastic, but it does need a little maintenance once in a while first thing it does help to remember to empty the barrel if you don't empty the barrel out the builds up and goes everywhere and you'll regret it the woodsmith shop live. On the session, see a lot of use here and these filter stacks you see here.

This is where the exhaust comes out. Mostly we sought to find dust comes over and uh collect the woodsmith shop live the years inside of these stocks. And that's what I've been doing this morning. It's it's punishment. Over time, and of course, all that affects the efficiency of our system and that's what kind of inspired me to do. I'm gonna clean this out.

I've done later this year. I'll probably put a new set of filters in and then you'll probably see some future uh Thursdays. I'm gonna start chasing out some of the um dead ends and problems of piping. We've been over here about fifteen. Well, things have moved around quite a bit This situation is new to us and so I need to straighten out some connection points and remove some unwanted.

Uh I wanted a sheet metal on our system to get the smoothest cleanest flow of air that I can from our tools back here so there's a lot going on here cuz I mean you were talking about how they were even plugs in the filters themselves. Yeah there were so we've we've had some problems with um with the system.

Completely backing up and that's that's that's kind of our fault because the barrel over filled and you know just way up in the cyclone and then that causes a lot just to simply bypass the cyclone and end up in the stack. So when I when I open these bins up this morning, I found these were empty but I also found that I took everything apart.

There's a huge clot that saw this right here in here. That was preventing any of the dust from actually falling down into the the woodsmith shop live bin it was a complete mess so see drew short straw.

That's yeah. That's that's that's part of the uh all part of the fame of Glory. I don't care what's putting the creative and creative director.

That's right. So you're gonna and then, but we've also learned, is you know like even glass gates over time will wear out they will uh they won't wear out here. We have problems with getting hacked the gate mechanism to where they won't close anymore and so yes I was running around disassembling a number of larger games the woodsmith shop live massage out so that they can close completely because it's you know a little bit a little lost here.

Uh filter problems so things kind of a little bit uh little bit of anemic system. With all things like this, it's not very enjoyable when you do it, but it's great to get it done good things or anything else you got going on. I wish I had that alright, mister Steve.

Hey everybody. Working on the Sewing table got the drawers done there uh butler sides back your hand duck tailed in the front with just a data in the back. Seven drawers. The user parts for the woodsmith shop live back I'll go vertically and I'm working on a joint which is basically just a round over in a Cove with a little bit of a straight edge here, this will eventually get hinge so it'll go down so this will be the stationary top and that will be the leaf which.

So and then we have some hardware here. Actually I think it's thirty-one by Forty-four and I give you some room. Oh yeah. Just Still got we're waiting on knobs to come in shake her knobs and still got a lap the back and yeah, there's a lot of wood in this project so lot of parts that's about all. I got seems like you've been enjoying it.

Oh yeah I love cherry I like working at. Alright, let's see what Dylan's got going on? So here we are in the home stretch in the Martini glasses. I got a couple examples here that I uh turn yesterday um currently I'm working on the funnel for the Stem Martini glass.

We've got the stabilized piece of wood there and then the top part is the um is the resin so once I got. Turn down the shape I wanted I ended up doing a bunch of wet sanding and I'm about right now and I think I might keep going the woodsmith shop live little bit that ultimately would like this to be as transparent as possible.

Uh oh, it's got excuse me. It's got a negative rake on it, so which has been really nice to just. Um you know there's a couple little bumps in here which really aren't gonna be discernible to the the woodsmith shop live. But uh I did find two um I didn't do it as the woodsmith shop live with this.

I did set my death with a drill bit, so I knew how far to go down um to or I knew how I knew my depth so that way I can remove the appropriate amount of material what I went ahead and did on the other one on the Stem Martini glasses I once I when I had it checked up, I drilled my depth about a three inch drill bit and then I just basically kept switching out the drill bits and I had this kind of teared progression in here and that helped a lot with.

Again with the transition from you know the larger diameter down the smaller part of the bottom part of the Martini glass. It's tiered. There's kind of a graduated on the outside, so I've been kind of using this as a scraper, but also also as a parting to go along and that's kind of help me establish those individual tears.

And of course I've got about a half. Skew here and just do any sort of fine tuning and clean-up work. Um I'm kind of at the point now where on the fine tuning the funnel for the Stem one um and then it's just on to assembly and actually I'll probably end up doing a little bit more uh wet sand and then buff it out.

Make it kinda look like glass so um super happy with the way they're turning out. The woodsmith shop live I think they've yielded some really good results. Uh I know last week and the week before we kinda talked about the kind of the woodsmith shop live sensitive and kinda laborious process of kinda getting to the turning heart, which you know takes a fraction of time, but I think it's well worth it find itself really well is smaller projects where um you know if you got smaller pieces you're working with it just makes a lot safer.

So um I look forward to having a project an upcoming issue so next week uh we little bit further along with the woodsmith shop live couple other projects that I've got in the works right now is um doing um some kids bedroom furniture uh so look out for that.

I'm in the process of modeling that and then um I've got a project coming up for pop wood uh so hopefully we'll have some modeling for that. Thanks for checking in. Alright, we'll wrap things up over with Mark Alright. Hey, everyone well it would the woodsmith shop live that I'm in a magazine project with the state of my bench for actually I'm not messy to make it all.

I'm doing something um actually I'm working on my um seminars. I've been building some uh props this week so sign up for the seminar next Thursday, 11 AM central time and I'll be doing the woodsmith shop live seven out on my favorite tour, which is the so.

That's pretty much what I'm doing this week, wrapping up with my props on that. So yeah check in next week, We got the CT move along. Yeah got the CC going got some wheels on it last week um still got some drawers to put in there and I can wheel out Chris CC machine um area the woodsmith shop live then um yeah, then I'll get started on some um also doing some.

Cuisine projects lined up after I've done this and I'm doing my seminar so we'll get going on that and then Dylan is the woodsmith shop live be gonna be some plants for the kids are in furniture, so we got that to look forward to um pretty much it um the woodsmith shop live, that's all I got for you this week.

Thanks for tuning in everybody If you have any questions or comments or smarter bars that you wanna share have us answer them. On next week's uh episode on our The woodsmith shop live live, you can put them in on the comments on our Facebook page the woodsmith shop live otherwise like Mark, said his seminar on router tables will be next Thursday.

You can sign up for that at Woods Shop. Don't forget to take a look at the annual pass to get you registered for all twelve of the seminars for Twenty-one. There's a pretty good list there we're covering quite a few topics so other than that.

Everybody stay warm and stay safe. See you next week.

|

Used Jet Lathe Parts Uk Wood Shop Jobs Near Me Google Veneer Rolls For Sale Guide |

ftgbfrt

05.10.2020 at 23:34:24

Hooligan

05.10.2020 at 20:18:45

anastasia

05.10.2020 at 11:29:39

emo_girl

05.10.2020 at 17:20:48