Lathe Tools Parting Tool Zone,Jet Planes Emit Values,Pocket Hole Jig Bauhaus Ltd - Videos Download

Parting on the lathe is simple operation in theory, but requires close attention to detail for success. Failure to heed the following tips can result in destroyed parting tools, ejection of the part from the spindle, and permanent damage to the X-axis power feed on the lathe, so when Lathe Tools Parting Off 2019 practicing, lathe tools parting tool zone very close attention to what you are doing and have Mike or a senior TA supervise the first time you try.

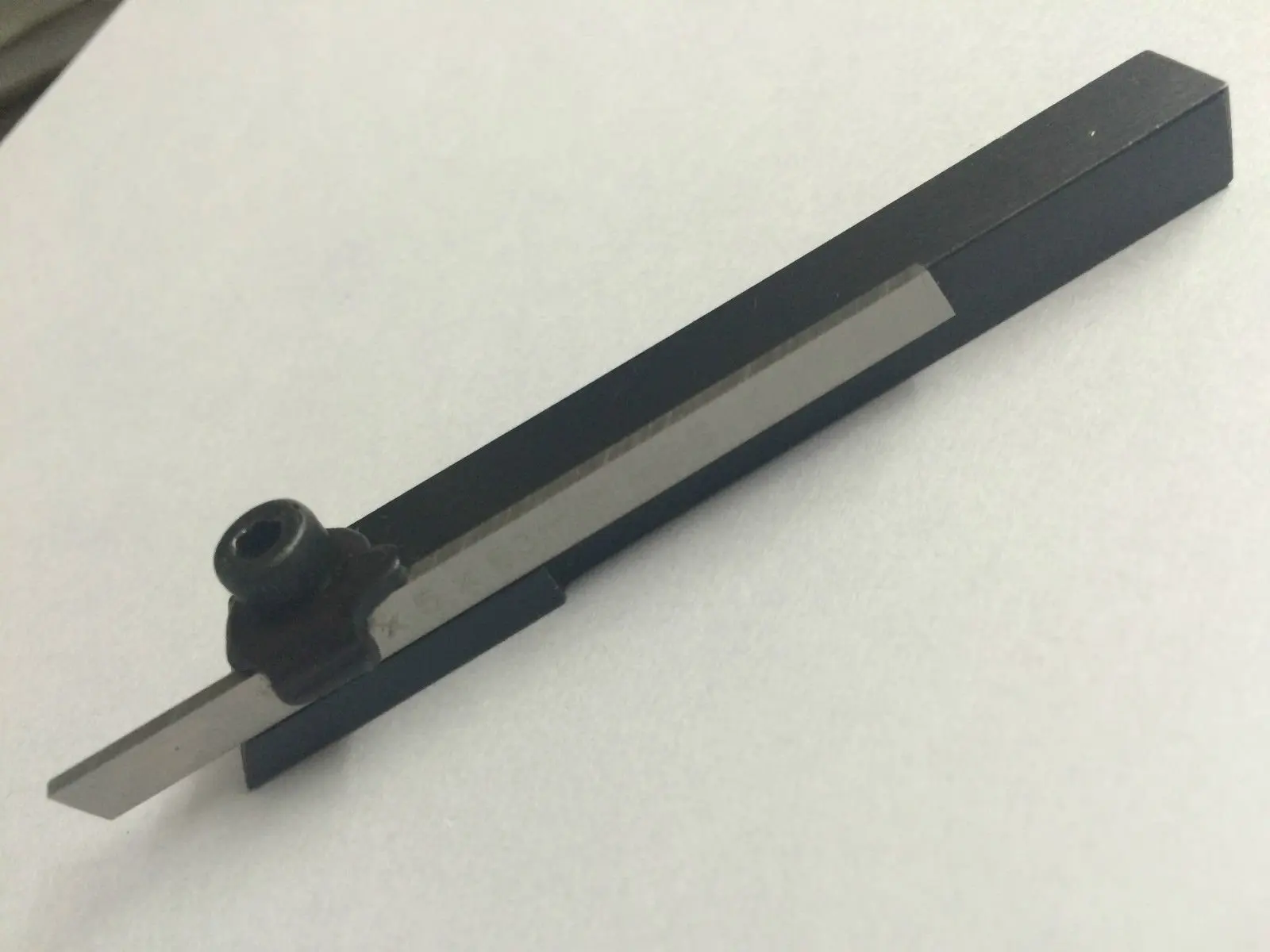

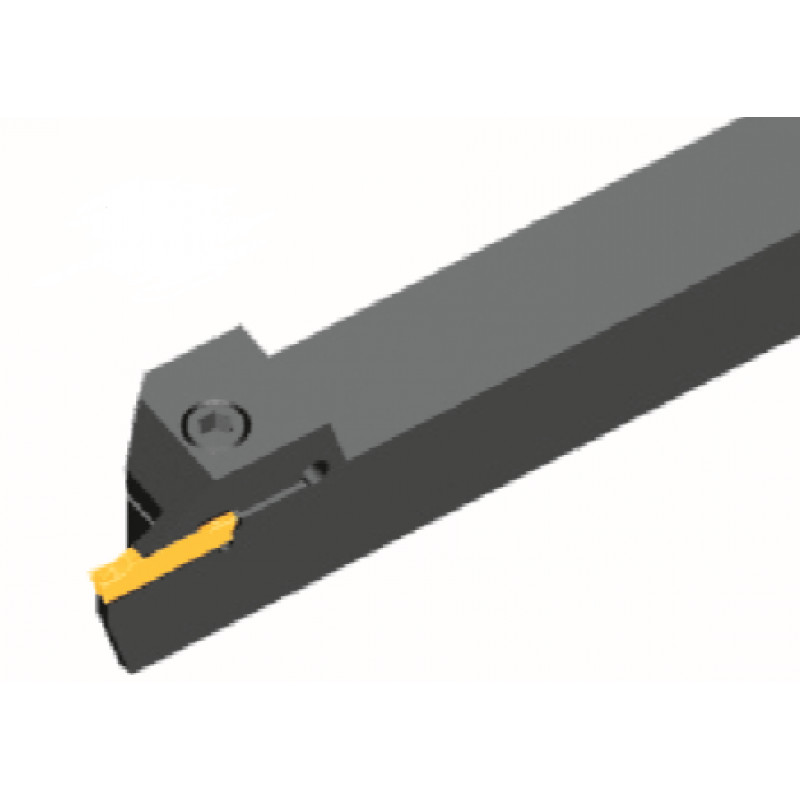

Step 1: Part-off Tool Selection. As aone in figure 1, there are generally two types of part-off or grooving tools: HSS and tungsten carbide. As usual, HSS is cheaper, tougher, and can be reground by hand once damaged. Lathe tools parting tool zone can tolerate much more heat, lathe tools parting tool zone once the insert is damaged it must be replaced with a new one.

Figure 1: HSS part-off tool left versus indexable part-off blade center and carbide insert right. There are many different styles of part-off inserts depending on the type of material being cut and insert effectiveness. In addition, carbide part-off inserts are available lathw high temperature coatings for use cutting ferrous and abrasive materials.

Figure 2: Carbide parting inserts are available with different rake angles and coatings like titanium nitride TiN for use cutting ferrous materials. Step 2: Part-off Tool Inspection. Inspect the parting tool closely before using.

If using lathe tools parting tool zone indexable part-off tool, check that the cutting insert is in good condition. Figure lathe tools parting tool zone Video on how to properly sharpen and use HSS parting blades. Step 3: Maximize Cutting Partijg Stiffness. Always maximize cutting tool stiffness by minimizing the length the blade sticks out beyond the toolholder block. For parting larger diameters or stronger workpieces, it will be necessary to adjust the stickout multiple lathe tools parting tool zone during partig parting operation, as the tool cuts deeper into the material.

Figure 4: Minimize the distance the part-off blade sticks out of the toolholder to increase tool stiffness during laths. Note the clearance between the toolholder and the part is also minimized. The blade should be adjusted shorter. Figure 6: To adjust the part-off blade length for a particular cutting depth, use an Allen wrench to lathe tools parting tool zone the screw in the back of toolholder which loosens the wedge at the front of the toolholder and allows the part-off blade to be repositioned at a different length.

Figure 7: It is better to perform part-off operations closer to the chuck right because of the decreased deflection when parting. Step 4: Align Part-off Tool. To function, the part-off tool must be perfectly aligned with the X-axis on the lathe. This can be done several ways; the most common two are using a block or a dial indicator, as shown in Figure 8.

Figure 8: To ensure the parting tool lathe tools parting tool zone perpendicular to the face of the chuck you can use a block whose surfaces are ground to be parallel to one another. Loosen the tool post, align the edge of the toolholder flush with the block, and re-tighten the tool post. Be careful to not drop the block. Figure 9: To ensure the parting tool is perpendicular to the face of the chuck you can alternatively use a dial indicator.

Attach the dial indicator to a Noga holder found in the metrology cabinet, and place gently on the guideways DO NOT slide the holder along the guideway; simply set it down in place! Position the contact tip against the toolholder and move the cross slide along the X-axis padting checking to see the change on the indicator. Like all tools used on the lathe, the part-off tool height must be checked and adjusted so it is as close to the vertical spindle centerline as possible.

If the parting tool is not on vertical centerline it will fail to cut properly, and will be damaged in use. Step 6: Feed by Hand lxthe Lots of Oil. For this reason, the part will also be VERY hot after parting. Like drilling, use pecks to break up the chips and apply more oil to the tip of the parting tool. This should break the chip center. The parting tool should leave a fairly smooth surface finish right. Miscellaneous Notes.

Part-off Surface Speed. The Feeds and Speeds resource document has an example of parting that will be repeated here for convenience:. Next, calculate the spindle speeds:. Note these are MAXIMUM values and lathe chuck safety must take precedence; spinning the lathe chuck at rpm is about the upper limit of what we safely do in the Lathe Tools Parting Tool Zoom lab, so lathe tools parting tool zone smaller lathe tools parting tool zone, do not lathe tools parting tool zone rpm, regardless of the calculation results.

Catching Parts. Figure Carbide Lathe Tools Tips Zone Parts with thru-holes can be safety caught using an undersized drill bit. NEVER try to catch a part by hand! Be careful not to zon the part-off tool into the drill bit. If there is no hole in the part, place a rag under the part to soften its landing. Here is a good video on parting tool basics using HSS blades. Step 1: Part-off Tool Selection As shown in figure 1, there are generally two types of part-off or grooving tools: HSS and tungsten carbide.

Step 2: Part-off Tool Inspection Inspect the toop tool closely before using. Step 4: Align Part-off Tool To function, the part-off tool must be perfectly aligned with the X-axis on the lathe.

Catching Parts Figure Parts with thru-holes can be safety caught using an undersized drill bit.

|

Cyclone Dust Extraction Examples Toggle Clamps Toolstation Quotes Build Your Own Wooden Window Frame Map |

Joe_Cole

28.05.2021 at 15:22:17

EPPO

28.05.2021 at 21:30:18

Parkour

28.05.2021 at 21:36:50

Azeri

28.05.2021 at 12:19:55

eden

28.05.2021 at 12:21:19