Large Finger Joints Woodworking,Grey Woodwork Ideas 2019,Buy Raw Wood Veneer Yoga,Lathe Tools Pdf Location - Plans On 2021

Crackle Finishing: Many woodworkers who try a crackle finish have inconsistent results. Senior Editor Glen D. Huey cracks the code of crackle finish and finds out that the easiest and most predictable way to do it is also the simplest.

We show you two actually three methods for doing it right every time with a block plane, sander and pencil eraser. And one more thing about the Summer issue: This issue is going to be mailed out to subscribers in a protective plastic bag, which will reduce the chances that the postal service will mangle it. If the plastic bag works for you, let us know so we can encourage our manufacturing division to continue using it.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Chris where are the instructions on bending the hinges for the sea chest? I mean, how does one saw in heels? Unlike readers of, say, a general interest mag. If people are worried about the environment, maybe you should offer an online subscription version PDF.

It all sounds good. About the wrap: glad to hear it as my first subscription issue came pretty beat up with bends and creases and crumples. About the photo: I thought either Schwarz had taken up flamenco dancing, or someone let a dominatrix into the workshop.

After many struggles with hand-cut dovetails, I decided to back up and hone my sawing and chiseling skills on finger joints.

I had almost instant success with the 90 degree angles everywhere, no tilting the board or the saw to hit the line. Marking the board is easier, too. Keep up the good work. The top photo is indeed disturbing, which is why I picked that one.

My foot looks so boring…. I hope this is only a temporary solution until we can add a protective paper wrap to each issue. Whatever minor scuffling the magazine gets along the way is small cost to pay for more info, IMHO. Hence, you will have to use expensive tools and equipment to make the joints. For example, you can use melamine-urea, urea, and PVA for interior parts and other nonstructural joints. On the other hand, you can use adhesives like laminated beams and phenol-resorcinol for exterior structures.

The most important thing to remember is to take into consideration the wood moisture and spread it evenly on the Finger Joints.

You may also want to avoid using water-based Wood Glue on the Finger Joints because it will swell the tiny area. So, it can keep them from joining. As mentioned, there are two major was in creating Finger Joints — by using a router or a table saw. Here are some of the fundamental tools and materials required to make perfect Finger Joints. Take note that it may vary depending on the size and kind of your project.

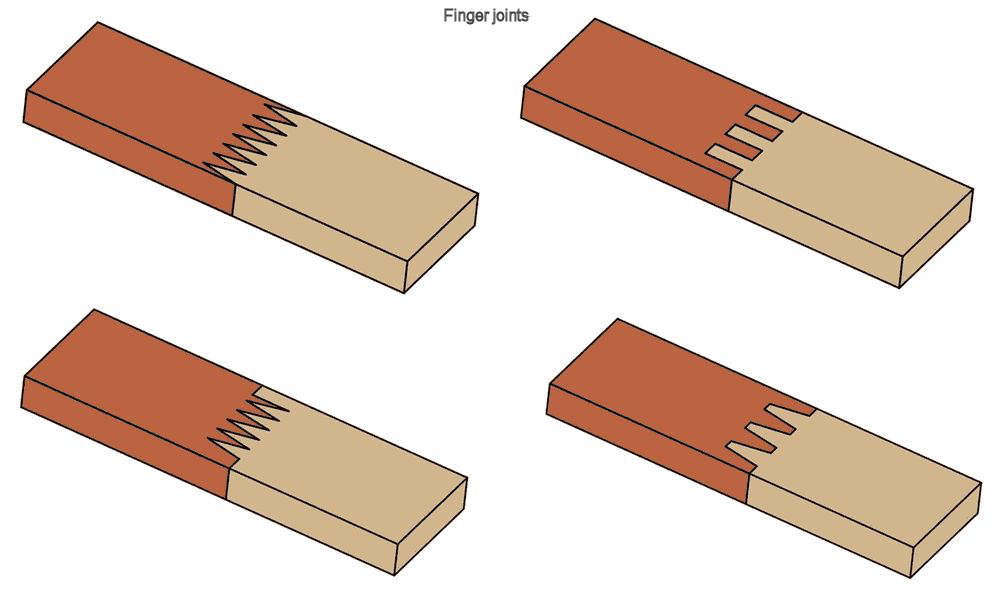

As mentioned, Finger Joints are a simpler version of the dovetail joint. Instead of cutting the pins and tails with a specific angle, you only have to cut the Finger Joints straight.

It consists of a set of fingers and grooves along the edges of two pieces of wood that interlock and glued together.

This guide will also help you make Finger Joints using a router. According to most experienced woodworkers, they believe that Mortise and Tenon Joint is the best corner wood joinery. It is a classic method that has been in the woodworking industry since its early times.

There are various wood joinery methods invented, but Mortise and Tenon Joint is still among the most reliable and most elegant methods for joining wood. Finger Joints are stiff for as long as you apply wood glue on its joints. Nevertheless, Finger Joints are sturdy enough to provide support even on larger projects. Wiggle the pieces of glued wood, and pull them apart to separate the joint.

Then, spray water into the gaps to weaken the Wood Glue. Apply heat or seam to lessen the tension until the wood joint separates easily. Overall, Finger Joints are perfect substitutes for Dovetail joints. It still requires accuracy in measuring, but the process of doing it is more straightforward and more manageable.

Finger Joints offer incredible support in any workpieces because of its interlocking profiles. As you are planing, mark the grain direction of each piece on both of its ends. Trim one end of each piece and redraw its grain direction mark. Photo 2. Arrange the pieces for one leg. To minimize tearout, position the pieces so that their grain all runs the same way. In addition, draw a large triangle across the assembly and number each piece.

Alternating pieces will get cut shorter later on, forming fingers—mark these pieces with a big X. Photo 3. Use a fence and a stop block to make sure that all of the holes are in the same position. Countersink both sides of each hole. Photo 4. Repeat the same process for the second table leg and the top. Glue dowels through both ends of all the even-numbered pieces of the top and legs Photo 4.

The dowels should fit snug, but not too tight. For the best fit, use factory-made fluted dowels see Sources. Position the dowels so they stick out approximately the same amount on both sides each piece, then wipe off all excess glue. Cut the dowels to final length on the bandsaw Photo 5.

Photo 5. Photo 6. Assemble each part of the table, without glue, and trim both ends. Take apart each assembly after cutting. Reassemble the top and both legs, then cut these parts to final length, trimming both ends Photo 6.

This step ensures that all the ends of the top and legs are perfectly flush with each other. Photo 7. Take apart the assemblies and trim the pieces marked with an X Photo 7. Photo 8.

Reassemble the top and legs Photo 8. The fingers should fit nice and tight in the notches, right? Not good! Photo 9. Rout the marked faces. Make a flat bearing surface by stacking other pieces alongside.

I chose to head off this problem by making the leg fingers a few thousandths of an inch thinner. On each leg assembly, mark one face of each finger with an X.

Take apart each leg assembly and rout the marked faces with a top-bearing mortising bit Photo 9. The cut is only a paper-thickness deep. Reducing the thickness of the fingers will make assembly much easier. Reassemble the legs and clamp them together.

Clamp the top assembly together, too, and try fitting the joints together.

|

Wood Duck Box Plans Ducks Unlimited Version Cnc Router Machine Tutorial Pdf Simple Wood Craft Ideas 03 Joining Router Bits Undefined |

A_Y_N_U_R

15.10.2020 at 13:26:50

liqa207

15.10.2020 at 10:11:33

Lady_Sexy

15.10.2020 at 12:23:11

Aida

15.10.2020 at 20:33:26