Jointer Plane Drawing Up,Quick And Easy Things To Make Out Of Wood Word,Rockler Woodworking Store Near Me Nz,Hand Held Circular Saw For Sale 10 - Tips For You

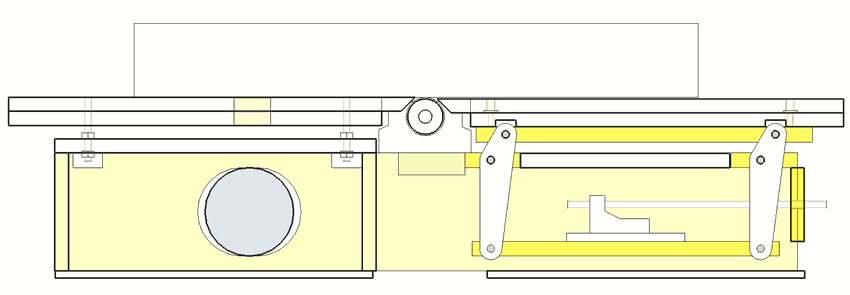

Simply loosen the bevel lock, position the triangle as shown below , move the fence until you see no gaps at the table or fence, and retighten the lock. Instead, check with the triangle every time you change the angle of the fence. But guess what?

All the machines still produced straight, smooth edges. Aim for a maximum variance of. These gauges are designed to set each knife exactly the same height above the surface of the cutterhead. Which you choose depends partly on the type of cutterhead your machine has.

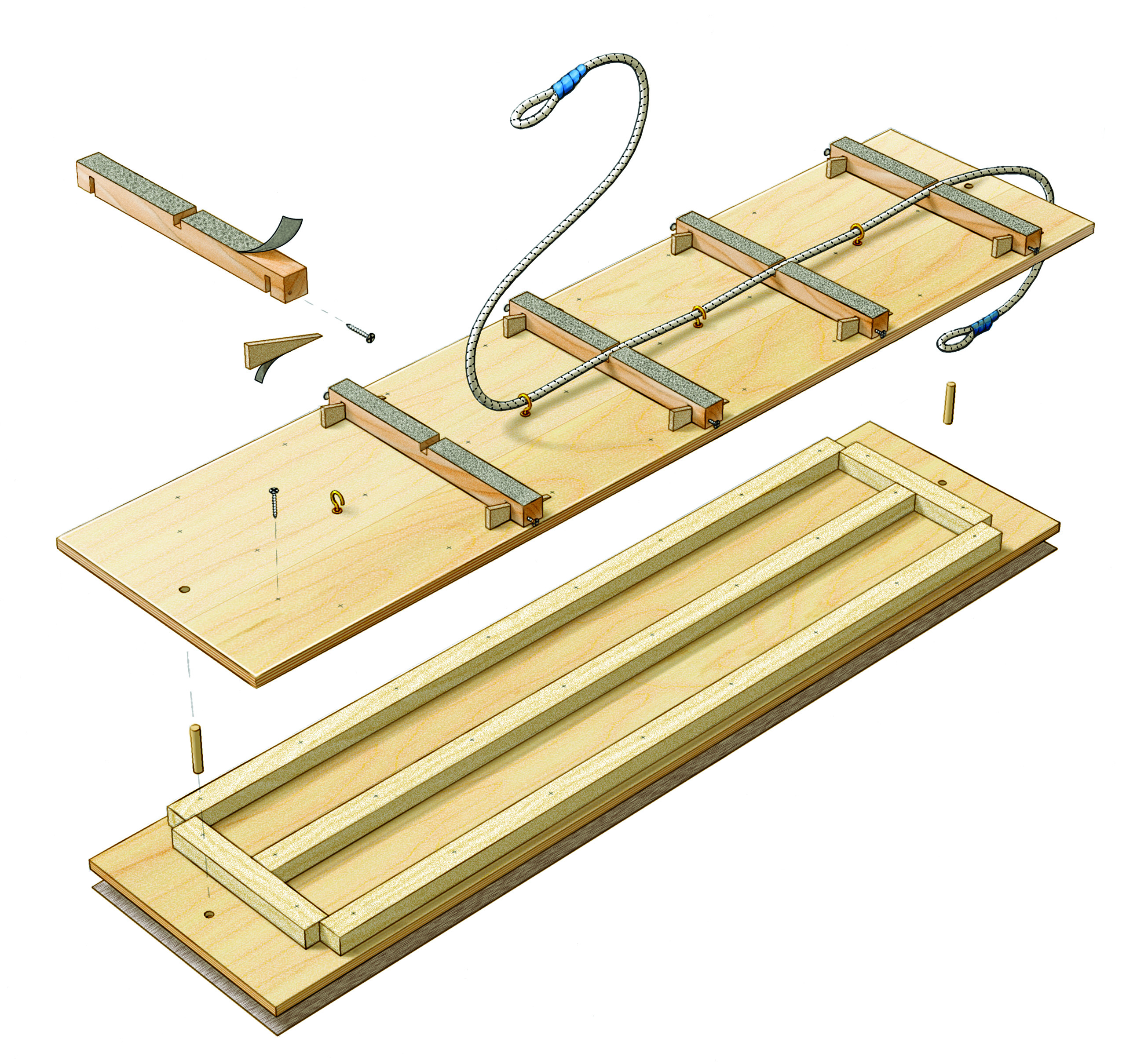

The first might be called the king of low-tech. It uses a simple wooden stick and a sheet of window glass. The glass should be cut to the width of the knives and about 12 inches long. To prevent cutting your hand, order polished edges. Then, follow Steps 1—4 in the drawings below. In Steps 1—3 mark No. It may help to keep light finger pressure on top of the stick.

After marking the cutterhead centerline on the fence, permanently scribe it with a scratch awl and triangle. To set each knife, rotate the cutterhead until the cutting edge of the knife aligns with the mark on the fence. Check the alignment by setting a triangle against the fence and touching the knife. Immobilize the cutterhead by inserting tapered wood shims between the head and bearings, as shown below.

Loosen the knife gib bolts just enough so that the knife moves with firm hand pressure. Raise the knife slightly higher than the top of the outfeed table. Now, lay the glass on the outfeed table, extended to fully contact the knife. Press the glass to the table and slowly snug up the gib bolts, starting with ones at the ends and alternately working toward the middle.

Too much torque can force a knife out of alignment. To limit the amount of pressure you can apply, turn the wrench with only your thumb and forefinger. Set each knife in turn, aligning it with the mark on the fence. Now, use the stick to check that each knife is set the same height as the others. Lay the stick on the outfeed table, lining up any one of the three table edge marks, and rotate each knife past it.

All should move the stick the same distance at both ends. For a high-tech way to set jointer knives, invest in a setting tool such as the Magna-Set. It consists of two steel or plastic bars that slide along a pair of parallel rods. As shown below, each bar has small but powerful magnets that hold the jig to the table and the knives. This keeps each knife flush with the outfeed table while you tighten the gib bolts.

A dial indicator setup, such as the A-Line-It, offers yet another way to set the knives. See the drawing below. The indicator tells you exactly how high the knives are from end to end, and in relation to each other.

These gauges work especially well with knives that you adjust with jack-screws that elevate the knives. Reinstall the cutterhead guard, Jointer Plane Height Online and plug in the machine. If you can move it, you need to adjust the outfeed table to exactly the same height as the tops of the knives. Now, shut off the jointer, raise the outfeed table until it just contacts the workpiece, and lock it down. To double-check Jet Jointer Planer Combo For Sale 82 this setting, finish jointing the edge and make a second pass, stopping to make sure the outfeed table fully supports the cut.

Use a shallow cut and keep pressure on the infeed side until 8" to 10" is supported by the outfeed table. Then, transfer pressure to the outfeed side. If any light shows through the joint, unplug the machine and recheck the alignment of the tables.

The true difference in these planes is in their intended use, and therefore in their sharpening and setup. The jointer plane, on the other hand, while resembling the try plane in appearance Jointer Plane Drawing 30 and length, is actually a joinery plane, not a surfacing plane like the try plane. With this in mind, it makes more sense for a jointer plane to have a straight iron like other joinery planes e.

Do not, however, confuse jointing the edge with truing the edge. If an edge needs to be squared to a true 90 degrees for example, the front of a case which will have a face frame applied , a try plane with a cambered blade will actually make the process easier. This process continues until the higher corner has been lowered sufficiently to make the edge square. On the other hand, when making a joint between two boards, one wants a flat edge for gluing. This is the purpose of the jointer plane.

Jointed edges need not be a perfect 90 degrees if the two boards are match planed. When match planing, the show faces of the two boards to be joined are placed together and the mating edges are planed at the same time.

When planed together, the boards can be opened like a book and the angles of the edges will be complimentary to each other, resulting in a flat panel. Perfect 90 degree edges are not necessary. A cambered iron cannot make this joint as well as a straight iron. Hopefully, this clears up some of the confusion surrounding the try plane.

You can see now that a 7 and 8 can both actually make very nice try planes or jointer planes. It all comes down to how Jointer Plane Drawing 500 you set up the iron. Tag: Hand Planes. I'm a passionate woodworking enthusiast of over 30 years, with an interest in the methods of pre-industrial joiners and cabinetmakers. I'm a furniture maker, teacher, and author, and I share my thoughts and experiences with the goal of educating and inspiring others who are pursuing the craft of traditional woodworking.

In addition to writing about and teaching traditional woodworking, I also build commission pieces for customers, and speak at woodworking shows and seminars. Just picked up an old try plane. Only problem I had in the 5 minutes I tried, is setting up that two part blade and the wedge.

Should be fun! This site uses Akismet to reduce spam. Learn how your comment data is processed. Remember Me. Not a member yet? Register now. Sign me up for the newsletter!

|

Titebond Liquid Hide Glue Expiration Date Cell Dewalt Radial Arm Saw Serial Numbers Windows Cedar Chest Lid Support Company Wormwood Tea Dosage |

Admin_088

30.09.2020 at 15:34:29

Rocklover_x

30.09.2020 at 22:21:50

VERSACE

30.09.2020 at 12:32:50

SmashGirl

30.09.2020 at 11:20:34

NiGaR_90

30.09.2020 at 17:24:30