D Way Woodturning Tools Windows,Do It Yourself Cement Garden Edging Dog,Pdc Machines Stock Future - Step 1

What I was originally pointing out, is that I now have two of Daves gouges that will not grind to the same profile as my others with the same grinding techniques. And repeating what I originally said, I am sure that there are those of you here who can freehand shape them, but freehand grinding has never been my thing. Bill Boehme said:. The shape of the grind that you get is determined by the shape of the flute whereas the jig One Way Woodturning Tools Online only controls the angle on the outside of the round bar.

I agree with Bill Blastic. It's the user and not the tool. Some grinds are more versatile than others, but that's about it.

Right, and that's why I can't get the grind I want on Dave's gouge, using my methodsThat's all. Clifton C. I don't think anybody here, unless they are new to turning, thinks there is a magical tool or grind, certainly not Tom.

I don't use the V gouge but one of the things I've seen with V shaped gouges is a hook or beak appear just behind the nose. The gouge then becomes vary aggressive and catchy. I've seen it enough to know that it's not just coincidence. It's something that happens to someone not used to sharpening that style of gouge.

Tom, My jigs are locked in, to change the tip geometry from bowl to spindle gouge I change the tip protrusion or a block in the V arm Wolverine. I have to change my settings when sharpening a V gouge.

I don't think you are going to have much luck with the parabolic flute settings on the V gouge. I know you don't like free handing, but you might get as close as you can to what you want and then reset the vari-grind to match. Curious to know, are you are seeing a little "hook" behind the nose? Best of luck, c. I think Dave's V is a bit deeper than Doug's. I do have one of Dave's U shaped flutes, and need a lot more time on it. I can get a swept back grind on the D Way tools, but I do every thing free hand on a platform.

With a round flute shape, as you roll the tool, you keep pretty much the same roll rate. With the more V shaped tools like Doug and Dave's, you spend a little time on the nose, almost none on the transition, and most of the time on the wing. If you spend too much time on the transition, then you get a dip near the nose. I don't use the swept back grinds. Same with the inside of a bowl, down to the transition area where I use a bottom tool.

With the swept back gouges and the 60 degree bevel, I think it may be more efficient to work with the low handle and cutting more with the wings, which works fine on the outside of the bowl, but not so much on the inside. When I try 60 degree bevels for wall cuts, they just don't feel right, even though they used to, and am at a loss to explain it.

Part of that may be because I got used to using other tools. They may work fine for roughing, but I prefer scrapers for that. I have been turning some Norway maple lately, and don't like it because it is kind of stringy and difficult to get a clean cut.

My standard shear scraping tools do an okay job, but not as good as I want. I tried shear scraping with a swept back D Way, and it seemed to cut better than the burnished burrs on my scrapers. Possibly because of the more acute angles on the wings. I can't think of any other differences that could account for it Not sure I ever heard it explained so that I understand it. Near as I can tell, the wings on jig sharpened gouges are more acute than the ones on hand sharpened gouges It is very easy to get a dip right past the point on the thompson V gouge.

You simply have to lighten up your touch to the stone as you go through that area. Clifton C said:. If you spend too much time on the transition, then you get a dip near the nose Yea I guess nothing fits.

Another example. The nose would be close to the same but the wings would be noticeably different. You know, I wish I were good enough that a U vs a V groove mattered. RichColvin said:. Yea I switch back and forth between my various U and V shapes trying to learn the differences and really it's pretty minor except for some of the special cuts I use.

I love my oldest U shaped no name gouge. I have a long left wing on that one and it's used for special pull cuts. The wings are very thin and have a very acute edge so it cuts really clean with the handle down really low using a pretty extreme angled cut. Still trying to figure out why or if that's an advantage. It has been good learning to hand sharpen that grind.

Hand sharpening improves your fixture sharpening skills. As Bill said the fixture only helps get the shape you still have to control the cuts to get an accurate properly shaped edge. Repeatability is what the fixtures help you get and as you said it's really really important. Repeatability not only improves the edge, it saves metal, and also makes the turner feel more comfortable about finding the bevel.

Early on my bevels looked more like a faceted diamond and I always felt like I was searching for the cut. It was probably me more than the edge at that time but after I made my copy of the Wolverine jig my edges were consistent and gave me the confidence to trust the edge and then try to solve the problem of the less than perfect turner.

I have another U shaped gouge that has a narrower U groove. The wings on that one are much less acute after sharpening and hold an edge longer when roughing. I have always referred to flute shapes as being more open or closed. I also have never understood the reference to flutes being open or closed when turning as it relates to orientation Reed I've just talked to a bunch of turners to find out and the best consensus is a closed flute means the tool isn't cutting.

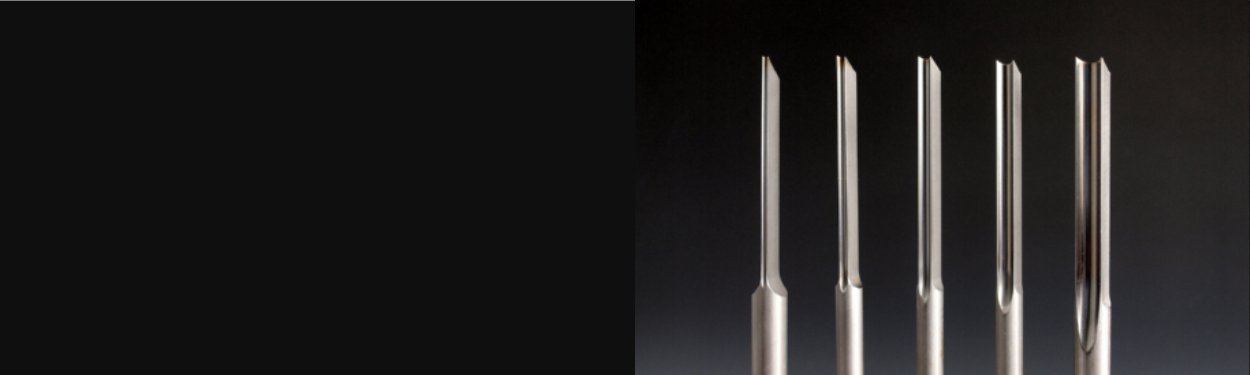

INside a bowl this would be with the flute at 3 oclock and outside with the flute at 9. Compare Now. Please wait Sign in or Create an account. Currency Displayed in. View Cart 0. Toggle Top Menu. Main Navigation. Add To Cart. Heat treating is accomplished with nitrogen in a vacuum chamber to prevent contamination. The steel is then triple tempered to achieve a hardness of 64 — 66 HRC, yielding a hard but not brittle material.

The result is an very durable edge that retains its sharpness. All flutes are individually inspected and hand polished to remove machine marks.

This extra step assures the sharpest cutting edge and smooth removal of shavings. All tools are shipped sharp and ready to make shavings. These tools are the perfect combination of durability and sharpen-ability, allowing me to hone all edges to razor sharp, raise a hook on my scrapers, or just simply use straight from the grinder. I have seen D-Way Tools evolve from their beginning and have absolutely everything positive to say about the quality, craftsmanship and user-friendly designs!

These American-made tools have continued to impress me and are the clear choice for partnering to create my E. Lofstrom signature tool series. As a professional woodturning instructor and demonstrator I have yet to find a tool line that compares. D-Way Tools are the highest caliber turning tool available! These are the very best I have ever used.

The 80 grit reshapes tools so quickly with no clogging or dressing up. The grit gives a superb cutting edge. I have over 60 tools to sharpen before a Masterclass and now can do it in record time.

|

Pull Out Pantry Drawer Slides Python Best Rap Topics Year 2 |

JAGUAR

03.01.2021 at 16:52:17

polad_8_km

03.01.2021 at 22:42:21

Samira

03.01.2021 at 18:23:22

ALINDA

03.01.2021 at 12:11:24

kisa

03.01.2021 at 12:56:37