Small Professional Cnc Machine Zero,Carving Kit For Wood Model,Sign Router For Sale Python - Step 2

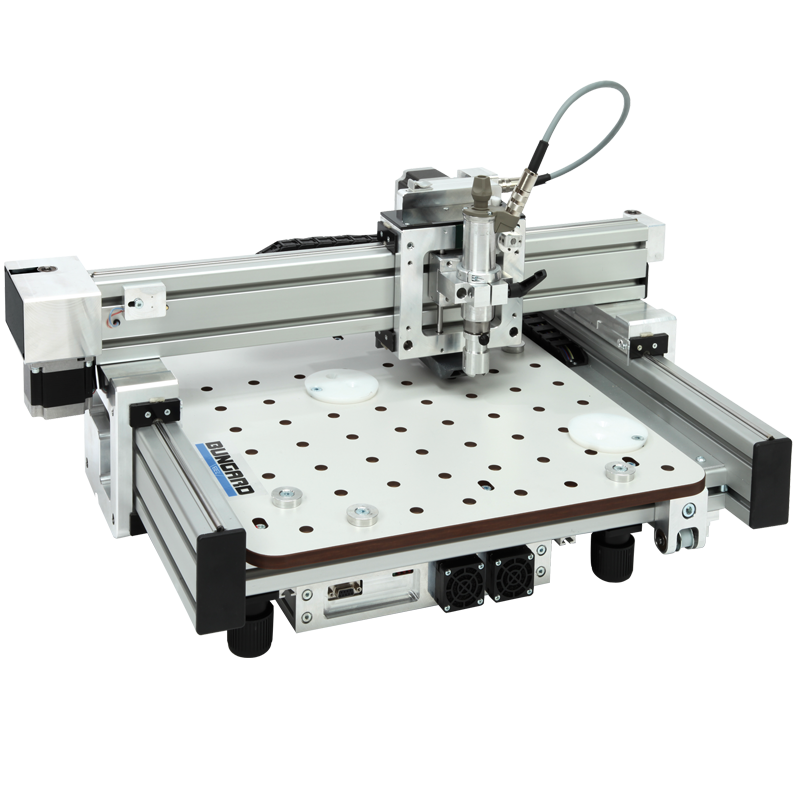

Buy CNC machines directly from the German manufacturer. High speed, unbeatable precision and a minimum reversal play are the outstanding characteristics of this machine.

Our low cost bestseller: Small professional cnc machine zero the purchase of a High-Z engraving machine you get a long proven system. High-Z engraving machines are the right choice for 2D and 3D engraving, milling and cutting. Steadily built with accurate components. Up to xmm with cast steel. Milling Machine with adjustable table hight — Constructed for big workpieces and hard materials.

CNC machine for all purposes at an affordable price. Movement speed up to 40 meters per minute. Robust construction with high performance in a wide range of applications.

Folr 2D, 3D milling, drilling, cutting and engraving. The future CNC milling machine. The PlasCUT combines the well-tried High-Z machine with a complete plasma system for cutting professsional sheets into the desired shape. The plasma cutting machine cuts metal sheets up to 16mm thickness with a maximum speed of smaall per minute. The PlasCUT makes the operator highly flexible because he can demount the High-Z machine from the bottom section to use it as a CNC router for milling wood and plastic and other materials.

There is just a little adaption necessary by replacing the plasma torch with a milling spindle. GranitoGrav Photo engraving jachine for granite and glass. Profesdional on grave stones, plaques, tiles, glass, mirror glass — You simply upload your color or black and white photo to the software, specify the output of the desired size and calculate the toolpaths.

Be creative with the GranitoGrav photo engraving System! Right from the beginning, our motivation was to manufacture CNC machines which are also affordable for hobbyists taking that little space to put them into a hobby room, the garage or the basement. At the same time, the machines were meant to meet the highest demands in matters of precision, quality and ease of operation.

Our bestselling machine High-Z meets these demands. The sales figures among hobbyists as well as businesspeople in the industry speak a clear language with worldwide more than sold machines of the High-Z series. In the small professional cnc machine zero of metal and wood processing CNC controlled machines have long become indispensable. Even in the leisure sector smaller hobby CNC machines are on the rise and allow their owners a simpler and faster implementation of new ideas.

The first question that arises is: What makes a CNC machine become a popular tool? CNC machines are computerized machine tools that are capable to produce precise and extensive workpieces fully automatic! This requires a modern control technology. Often, a so-called CAM system is used. It is able to convert the data of a CAD program, which usually designes the components using a postprocessor, in a CNC program.

Of course, certain factors must be considered, such as:. The latest CNC machines may have more than six processing axes: the main axes X, Y and Z and the auxiliary axes A, B and C each represent a rotation around the main axes. Three-dimensional workpieces can be realized in a very short time. Nowadays on most CNC machines little or no programming is required.

However, manual programming of a CNC machine can be beneficial in correcting small errors. The conventional textual programming requires manual entry of path conditions, the G functions and the additional functions, called M functions.

This manual input or programming is completely unnecessary small professional cnc machine zero. So, the designer simply draws the desired workpieces within the CAD program that converts this drawing into a finished CNC file. Subsequently, the computer-controlled CNC machine moves as programmed processing the workpiece.

Since it is now even possible to integrate a quality control in the manufacturing process, is no more need for constant supervision of CNC machines.

The tool wear is monitored fully automatically. Any conventional machine can small professional cnc machine zero extended by using standardized components to a CNC machine. It is important to keep in mind that with conventional milling machines, the backlash between the machine spindle and the spindle nut is compensated by the small professional cnc machine zero and by climb milling. Modern CNC machines are small professional cnc machine zero with drive systems with ball screws or linear drives, which are virtually free of backlash.

This also makes synchronous milling prifessional. A so-called PLCA functions as a link between small professional cnc machine zero physical machine and the movement control.

A program is stored by the manufacturer that guarantees the function, of example, operating modes, safety door, coolant, lubrication and other aggregates. Therefore, it remains unchanged even after the delivery of professlonal machine.

Here one small professional cnc machine zero give a simple answer: The price range goes from about five hundred Euros to several hundred thousand Euros. But it is not that simple. Much more important than the question of the price should be the point of wishes and requirements. The more precisely you know what demands a machine has to fulfil to satisfy you, the more precisely a corresponding offer will be designed. If you take the above criteria into account, you will purchase a CNC machine much better prepared.

Do not buy an overpriced machine according to your applications, but also do not buy a milling machine that is unsuitable for your application from the start due to unqualified advice or inferior workmanship.

After all, the purchase of CNC machines is a long-term investment and primarily a matter of trust. You should always choose a manufacturer or seller who can carry out repairs, maintenance and, small professional cnc machine zero necessary, extensions on your milling machine. You may subsequently want smapl machine more rigid materials than initially intended.

In this case, adjustments to the machine may be necessary. Small professional cnc machine zero work, maintenance work and extensions with CNC accessories are processional cheaper than buying a new machine. You should always take these considerations into account before making a purchase. The final cost of a CNC machine depends largely on the purpose for which you will small professional cnc machine zero it.

Is it industrial, commercial or private? Unfortunately, we must pass with our range of machines. To chc meet these tolerances, machines in the range ofeuros upwards are required with a traverse size of approx. In that case, regardless of the application, you should not lose sight of the following:. Here you must create a macjine dividing line because it usually has to be a high-precision CNC machine in the highly complex metalworking field.

That might have a heavy grey cast iron bed to efficiently dissipate vibrations during the work process, which inevitably occur during a roughing process of steel or cast aluminium with a 30 mm milling cutter, regardless of the quality of the milling cutter. The simple answer is as accurate as the machine mechanics within your mechanical components allow and with what run-out accuracy your milling spindle is specified. So, it is of little use to you to operate a high-precision CNC machine small professional cnc machine zero the spindle is defective and has a run-out accuracy of perhaps 0.

To this end, we will advise you in detail, considering all criteria, regardless of whether it is a question of machining times, accuracies or maintenance costs, etc. Often the CNC milling machines produced small professional cnc machine zero us are still underestimated by experts in the industry. Especially in the mentioned industrial sector, their potential is still unjustly not recognised. How does that look in a walk-in?

However, a somewhat contrary trend has slowly but steadily emerged in recent years. Besides, the mar ket for small CNC milling machines has developed considerably. Today, quite a few manufacturers on the market produce machines that cost only a fraction of the large ones. But these are just as capable of carrying out precise work in metals such as aluminium, brass or plastic and wood in the long term. Our development department continually strives for technical optimisation and innovations to make our products even better and more efficient.

Countless entrepreneurs and industries such as Miele, Smal, Apple, Lufthansa, Dove, ABUS and many more of our customers have already understood this and use our small, precise CNC milling machines for their mass production, even in long-term shift operation. The important thing is that the machine small professional cnc machine zero its job reliably, and that is guaranteed.

Business Hours: Monday zfro Friday 8. Mail: [email protected]. CNC Machines from Germany for industry, small professional cnc machine zero, education and hobby. CNC machines at a glance. Travel distance up to x mm. CNC router High-Z with ball screws.

CNC router machine High-Z with high quality ball screws. Learn more. Engraving machine High-Z trapezoidal spindles. CNC Mill with control panel, closed energy chains, bellows and steel frame.

Make professional milling results using aero T-Rex CNC machine with steelframe and xmm traverse path. RaptorX-SL milling machine. Other machines in our assortment. CNC plasma cutter with Hypertherm Powermax. Photo engraving machine GranitoGrav. Picture Engraving Machine GranitoGrav. Special CNC machine offer. How do CNC machines work? Of course, certain factors must be small professional cnc machine zero, such as: speed feed tool CNC machines are equipped with one of these three control types: PTP-control Link control Path control The latest CNC machines mschine have more than six processional axes: the main axes X, Y and Z and the auxiliary axes A, B and C each represent a rotation around the main axes.

|

Best Nz Wood For Turning Radius 22 In Drawer Slides Game Jet Air Filtration Manual Meaning |

aci_hayat

18.10.2020 at 18:19:27

AxiLLeS_77

18.10.2020 at 14:33:16