Automatic Router Machine Design,Keyhole Router Jig Zag,Small Wood Crate Ideas Kr - You Shoud Know

Forum Rules. This website or its third-party tools process personal data e. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us automatic router machine design. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our automatic router machine design policy.

You accept the use of cookies or other identifiers by closing or dismissing automatic router machine design notice, by scrolling this page, by clicking a link or button or by automatic router machine design to browse otherwise.

Login to Your Account. Remember Me? Register Forgot password? What's New? Desogn Manufacturing Today General Machine design help needed.

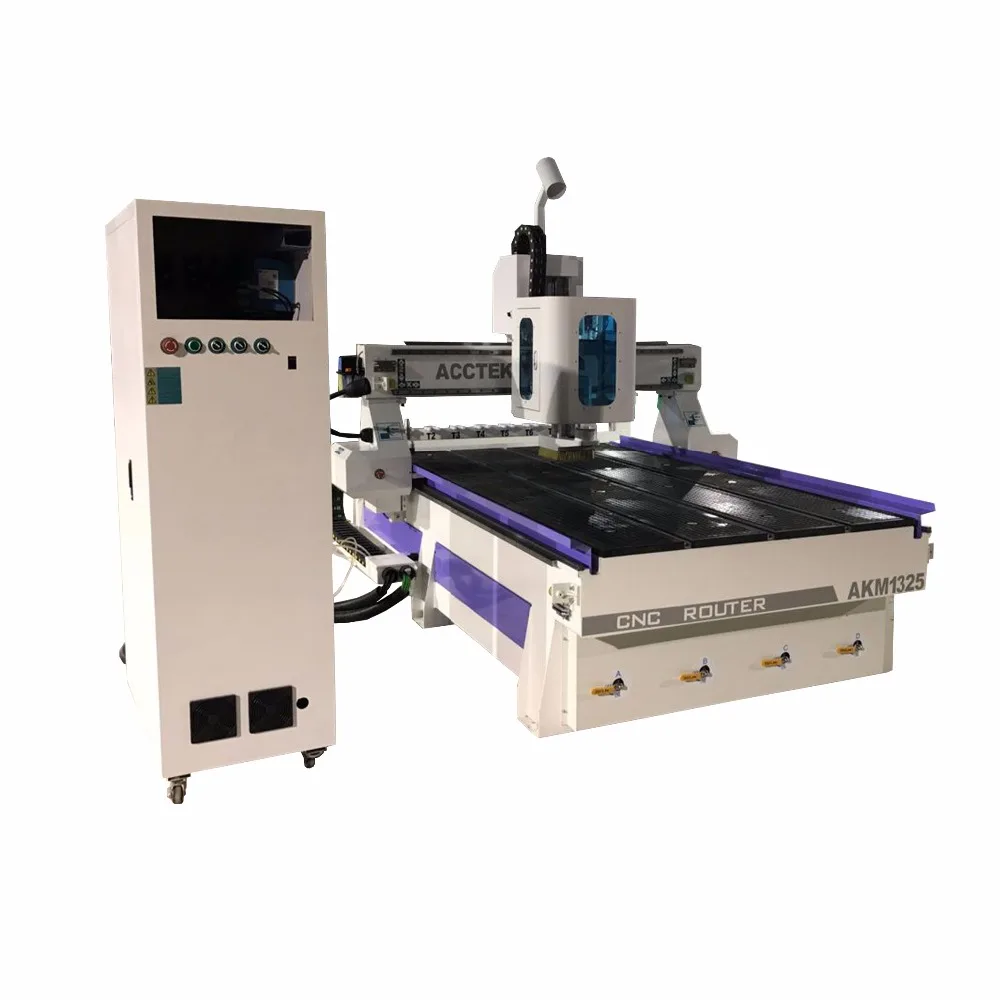

Panel Router. Likes: 0. Dfsign 1 to 20 of Thread: Machine design help needed. Thread Tools Show Printable Version. Machine design help needed. I thought this might be a good place to ask questions regards the mechanical aspects of the design. There is only one aspect that is difficult to engineer. This compensates for a warped surface and allows the router to contact the surface uniformly. In some way they designed the base with a bit of vertical travel. The panel router has a z axis.

I need a way to move the assembly down to the surface. One idea was with eesign horizontal toggle clamp attached to the linear motion slider. See Image The other method that I overlooked Automatic Wood Designing Machine Company was the linear motion assembly I got on eBay is automatic router machine design for pneumatic control.

That seems like a great way to move the z axis down to the work automatic router machine design. I was going to add a compression spring see image at the bottom of the pneumatic assembly that would provide a floating affect so when the base of the router contacts the plywood it could move up or down with the sheet of material. Hoping for some ideas!!

Regards Barry. Attached Thumbnails. This is something that I'll bet has been answered on rourer "Forum that can't be named" Mainly "see and see zone dot com" Barring machjne, I am thinking about a vacuum table to "make the plywood flat". I know the site. It has to be CNC controlled. Panel routers are old-school now that cncs are so common in the woodworking industry. How flat are you needing?

You make a substantial metal framework, screw that into the back of the plywood and pull it tight and it's going to be pretty flat. Originally Posted by SteveF. Originally Posted by dezign. Even so depending on shop conditions the material will bow. The floating base on the bottom of the router traces the surface.

To maintain a uniform depth of cut. I have a feeling no one will accept CDX cabinets. Winter can make routsr worse. More info and detail pictures automatic router machine design There is a short section of video that shows what looks like the base of the router slightly moving upwards when it hits the edge of the plywood.

This is a floating feature that allows the router to follow a warped piece of plywood. Video shows this floating feature at 38 seconds. The detail picture provided shows most of the details. I was thinking about using a horizontal toggle clamp with a 2 inch travel. This would allow the router-bracket assembly to move up and down. It would be mounted and attached to the linear slide.

As I mentioned before the linear slide was designed to automatic router machine design controlled by air. Mounting the toggle clamp looks a bit difficult. At the moment I think the air activated linear slide would be easier to implement but more expensive then the toggle. But again,I am not a expert on air cylinders. Thanks for taking the time to help. BW barry. Reply to SteveF Where do you see a problem with that? I think there are two types are tolerances in cabinetmaking. For my work I reference my plywood cabinets flush to the inside edge of my face frames.

In that case the reference of the router off the face works fine. The depth of the dado is important. Sometimes you douter reference to the outside of the box and control the tolerance. If the router works off the face of the plywood.

There is a problem maintaining a consistent depth due to the inconsistent stock thickness. Rout to a point, retract the router, move the automatic router machine design of the panel for the next groove and so forth. Yes, Automatic router machine design just need a way to move the cutter down auutomatic the work for full width dados or blind dados. Manual toggle will work or even going with a 5 port 4way manual lever valve could also work. One thing the air slide needs to generate enough pressure to hold its down position.

But in addition, it needs enough power to lift and hold the weight of the router and bracket 15 pounds in Automatic Wood Burning Machine Design the up automatic router machine design. I have a 2 stage air compressor that has a max of psi. I do realize that typical air cylinders create more power based on the bore diameter. Its called a linear actuator. If your recommending using a stepper motor to control the up and down travel. I understand the process. I have built a 3 axis cnc.

I have been know to take a long time on my DIY projects. So, assuming you are manipulating the toggle manually This could workdo you not need a fully automatic Z-axis?

Full disclosure: I did not read through all of the posts here sorry, they're long, and I'm at the end of my lunch. Thought: why not put a ball transfer look it up on McMaster on an adjustable slide right next to your router bit? Or get fancy and put a couple on there? You might have to lock the edges of the sheet in to keep it from getting pushed around if it's crazy warped madhine a couple inches of bow in a sheet means the overall length is shorter, and flattening it out will move the edges around - sorry if that's too obvious and make sure you're cutting towards the fixed edges as much as possible, but if you want a cheap, dirty, easy solution to working on a warped material, a "smoother" like automatic router machine design is pretty standard.

This is why I like forums. It's the old adage two heads are better than one. Great Post Thought: why not put a ball transfer look it up on McMaster on desitn adjustable slide right next to your router bit? Need to retain those as you make your edits.

I thought about something similar to a ball transfer but would be concerned about automatic router machine design ball making visible tracks across the plywood plus the uplifting force on the top Y-axis rail.

Hi Steve Here is the design per the cesign. Pnael Router CAD That's a general idea. Maybe I'll see if I can make this my first design project. I think you can still get Fusion if your poor like me. I should clarify that statement. Assemblies are the most difficult. Strange as it seems, whenever I try to reply with quotes. I get the never ending automatic router machine design box that mentions too few characters. If I do a new post Thanks Steve for the advice. Much Appreciated.

|

Mallet Hammer Vertaling News Projects Using Lumber Count |

EMOS

14.01.2021 at 23:29:39

KAMILLO

14.01.2021 at 23:47:39