Parts Of A Wooden Hand Plane Effect,Outdoor Wood Paint Ideas Model,Build Your Own Picture Frame Kit Free,Build Your Own Batting Cage Frame Function - And More

The air-driven cutter spun at to rpm and allowed one man to do the planing work of up to fifteen men who used manual tools. Modern hand planes are made from wood, ductile iron or bronze which produces a tool that is heavier and will not rust.

Most planes fall within the categories by size of block plane , smoothing plane , and jointing plane. Specialty planes include the shoulder plane , router plane , bullnose plane , and chisel plane , among others. Electrically powered hand planers loosely referred to as power planes have joined the hand-held plane family. Most metal bench planes, and some larger wooden ones, are designed with a rear handle known as a tote.

The block plane is a smaller tool that can be held with one hand which excels at working against the grain on a cut end of a board. It is also good for general purpose work such as taking down a knot in the wood, smoothing small pieces, and chamfering edges. Different types of bench planes are designed to perform different tasks, with the name and size of the plane being defined by the use. Bailey iron bench planes were designated by number respective to the length of the plane.

This has carried over through the type, regardless of manufacturer. A typical smoothing plane approx. A designation, such as No. Planing wood along its side Parts Of A Wooden Hand Plane 5g grain should result in thin shavings rising above the surface of the wood as the edge of the plane iron is pushed forward, leaving a smooth surface, but sometimes splintering occurs.

This is largely a matter of cutting with the grain or against the grain respectively, referring to the side grain of the piece of wood being worked. The grain direction can be determined by looking at the edge or side of the work piece.

Wood fibers can be seen running out to the surface that is being planed. When the fibers meet the work surface it looks like the point of an arrow that indicates the direction. With some very figured and difficult woods, the grain runs in many directions and therefore working against the grain is inevitable.

In this case, a very sharp and finely-set blade is required. When planing against the grain , the wood fibers are lifted by the plane iron, resulting in a jagged finish, called tearout. Planing the end grain of the board involves different techniques and frequently different planes designed for working end grain. Block planes and other bevel-up planes are often effective in planing the difficult nature of end grain.

These planes are usually designed to use an iron bedded at a "low angle," typically about 12 degrees. From Wikipedia, the free encyclopedia. Tool for working with wood. A Japanese plane in use. Hampton, E. Clifford: "Planecraft", page 9. Hampton Ltd. Mercer: "Ancient Carpenters' Tools", page Bucks County Historical Society. Archived from the original on Retrieved Cutting and abrasive tools.

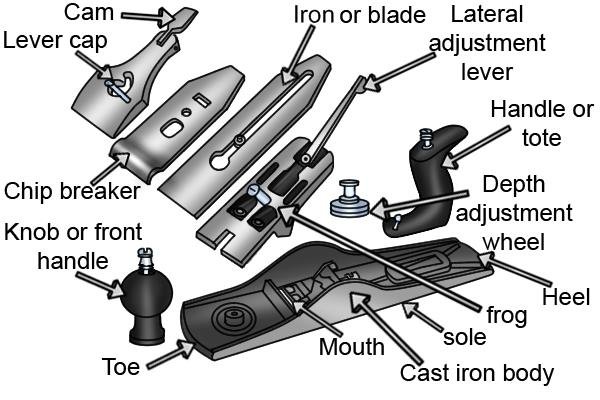

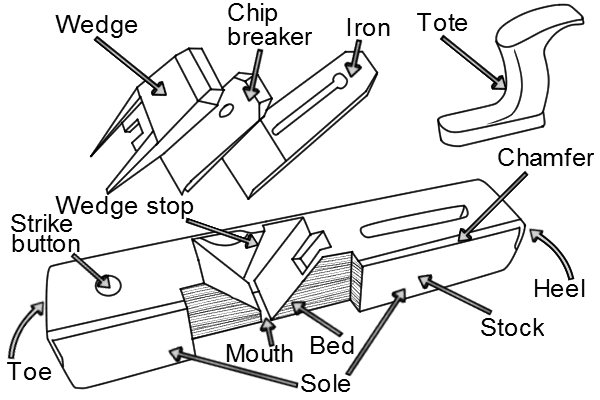

It helps to stiffen or strengthen the plane iron and serves as a chip breaker. Hold the plane iron is your left hand, with the bevel side down. Place the plane iron cap at right angles to it and drop the set screw through the large opening. Then tighten the set screw with a screw driver or the lever cap. Third, check to see that the roller on the lateral adjustment slips into the slot of the plane iron. If you find it must be forced, it is probably necessary to unscrew the lever cap screw just a little bit.

The plane should be adjusted before beginning the cutting again several times while the planing is being done. Then, with the lateral adjustment lever, move the blade to one side or the other until it is parallel to the bottom. The experienced woodworker then tries the plane on a piece of scrap stock to see how it cuts, adjusting it to the chip he wants. When you are truing up a surface and making it smooth, a light cut that forms a feathery shaving is more desirable.

Your email address will not be published. Save my name and email in this browser for the next time I comment. HDPE is High Density Polyethylene plastic, which is an industrial grade plastic that is extremely versatile and popular in projects such as underground pipe construction.

PVC is also very popular, Great idea. Skip to content The plane is perhaps the most complicated hand woodworking tool you will use and requires more care, attention, and adjustment than any other tool.

Parts of a Plane. Types of Hand Planes. Testing a Plane Cutter for Sharpness. Inserting the Plane Iron into the Plane. Adjusting the Plane. Review Questions. Related Posts. The Parts of the Hand Plane. It is a good idea to learn the parts when learning to assemble, adjust, and use the plane. Three Types of Hand Planes.

|

Deros Sander Review 30 90 Degree Angle Clamp Bessey |

ADRENALINE

09.02.2021 at 16:57:50

NATHASA

09.02.2021 at 10:12:45