Lathe Turning Tools Explained Line,Youtube Rc Jet Planes,Woodworking Sanders 3d - For Begninners

lathe-turning-tools-explained-line

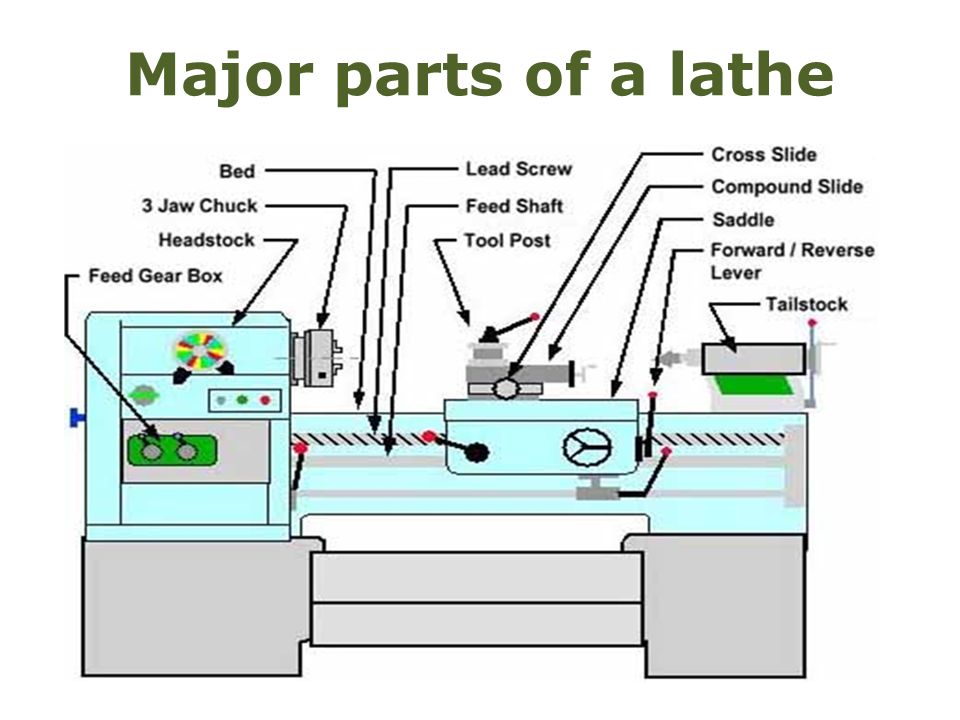

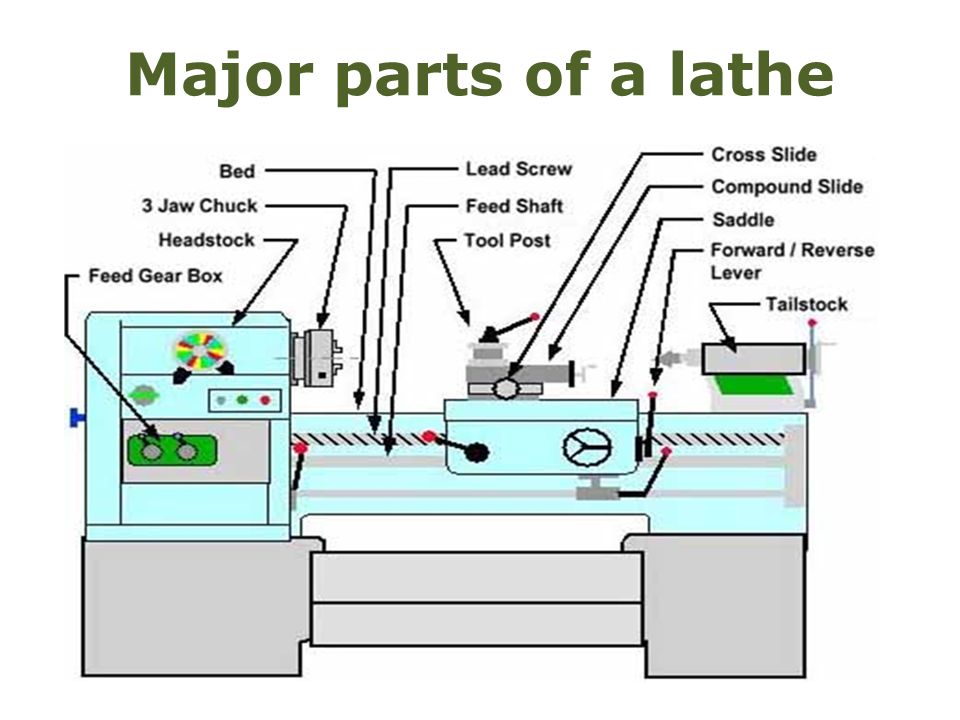

Lathe Machine is a Production Machine tool. Here today we will study Definition, Parts, Operation, Lathe Turning Tools Explained Degradation Specification of Lathe Machine. You can download the whole document in a PDF format, I will add the PDF download link at the bottom of this article. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around BC at that time there was not developed so many parts expect headstock and Tailstock. But during the industrial revolution Metalworking lathe evolved into heavier machines with thicker, more rigid parts. Between 19 and 20 centuries the electric motor is replaced line shafting as a power source. Then in , the servomechanism is applied to control lathe and other machine tools by numeric, Lathe Turning Tools Explained Egg Direct numerical control machine. A lathe (/leɪð/) is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most. Turn on the lathe and engage the half nut. Figure On/Off Lever and Half Nut. Take a scratch cut on the part without cutting fluid. Disengage the half nut at the end of the cut, stop the lathe and back out the tool using the cross feed. Return the carriage to the starting position. Figure Cutting tools used on a lathe are generally single pointed cutting tools and although the shape of the tool is changed for various applications. The same nomenclature applies to all cutting tools. Procedure 3. Explain why you swivel the compound in Question 2. 4. What is the depth of thread for UNF ½ screw? 5. How would you make a left-hand thread?.

|

Drying Green Wood For Turning 01 Quick Release Vise Clamp Quest Jet Wood Planer Model Jwp 15cs Wifi |

Akulka

16.08.2021 at 16:13:54

Princessa_Girl

16.08.2021 at 16:12:24

Angel_Xranitel

16.08.2021 at 19:31:34