Lathe Tool Height University,King Canada Belt And Disc Sander Facility,Joe Woodworker Veneer Supplies Kit,Carpentry Shop Practical File Template - And More

Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website. For the best site experience please disable your AdBlocker. Home What's new Latest activity Authors.

Photo Gallery New media New comments. Downloads Latest reviews. Groups Public Events. Log in Register. What's new. New posts. What's new New media New media comments New downloads Latest activity. Log in.

Install the app. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser. The "why" Of Lathe Tool Height.

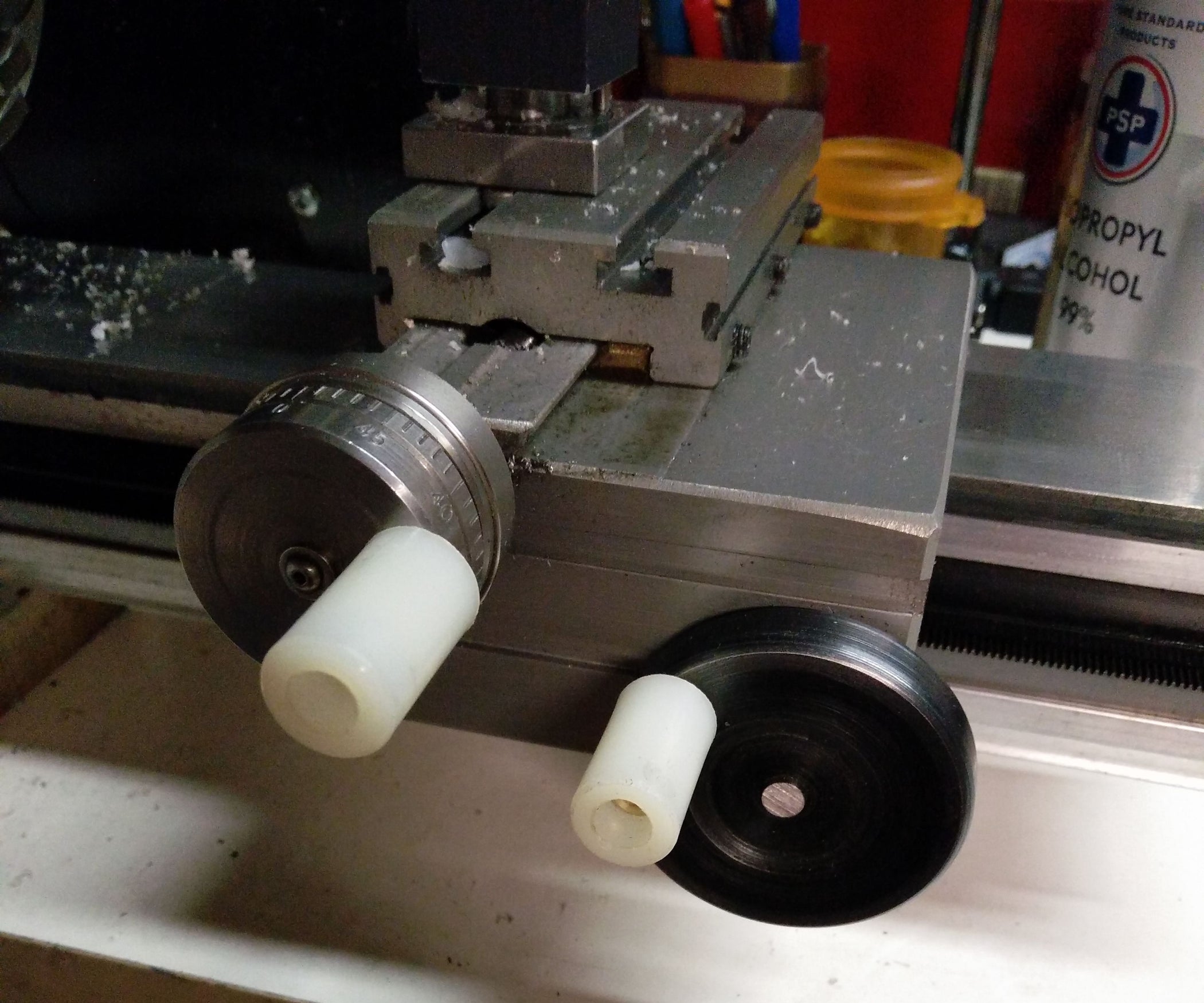

Thread starter dogma Start date May 1, Tags lathe tool height. Joined Apr 28, Messages I started lathe tool height university to use a manual lathe towards the end of the last year and I have seen conflicting advise for the proper height of lathe tools. Often, I see a forum post with advise along the lines of "at center or slightly above" but I have also seen lathe tool height university opposite of "at center or slightly below".

I'm curious as to what the technical basis is for the tool height to be above or below center? Is there an authoritative reference for this information, Eg.

Joined May 2, Messages Well you are right that there are conflicting reports, but IMHO the right one is "at centre, or VERY slightly below" In this position the tool will cut well, if too far below it will tend lathe tool height university dig in.

Above centre will have a tendency to cause the tool to drag on the work below the cutting edge, and make a right mess! Imagine a tool ground with very little front face clearance in order to give maximum support to the cutting edge. If you go even slightly above centre you are presenting the front face of the tool to the work rather than the cutting edge. Joined Dec 2, Messages 1, If it's a form tool like a threading tool the angle changes if it's above or below centre.

Od turning the tool will rub if it's above centre. Id turning the tool will rub if it's below centre. Joined Nov 4, Messages I'm a "dead center" guy.

It seems to me if it is above, it pulls into lathe tool height university larger diameter as it deflects downward, effectively increasing the depth of cut. But someone once told me it depends on the geometry of the tool holding system too - downward deflection COULD move the tool away from the work in which case slightly above would make sense. All I know is that for me, on two different lathes, dead center results in the best performance for parting and turning.

JimDawson Global Moderator Staff member. H-M Lifetime Diamond Member. Joined Feb 8, Messages 10, You asked why do we set lathe tool as we do. I still don't really have an answer but I am lathe tool height university center and below guy. Seems to work well for me. Here a couple of threads that have a lot of discussion about this subject.

Joined Dec 20, Messages 8, Dogma, there is no authoritative source I know of that will tell you axiomatically that the tool must be set at center height. Most will recommend it, though. I can remember wondering the same thing about 25 years ago. As there was no internet like we know it today, I experimented myself and came to my own conclusions. Rather than take someone's advice, why not try it yourself and see what results? I'm sure the experience will prove which setting is best.

If you must go beyond the experiential, look up the Merchant Equation and read to your heart's content about why tool geometry is what it is and why the tip must be on center height. If you do this then maybe you can help me understand how that ol' fox Jim Dawson can get away with setting a tool significantly below center and getting good results!

I'm afraid to try it on my 11" lathe for fear of breaking the compound right off! Years ago during my apprenticeship I had two mentors. One advocated above center, the other below center.

I tried in vain to prove which lathe tool height university the better setting only to lathe tool height university out the truth. If lathe tool height university correctly above or below, neither is better than the other.

I practiced till I found which was better for me. I have no problems with this for most purposes. Yes, I lathe tool height university go below center to find the better cut, but not often.

Below center gives you a slight shaving effect IMHO. Center or above does no. Your choice. Use what you are comfortable with. Joined Mar 19, Messages 2, I use mostly certain grades of HSS.

I typically do not grind the top of the tool bit. And I really do not fuss about tool position relative to the work. I try and eye ball it to center and call it good enough. All this fuss I read about the cutter being high, center lathe tool height university low thing and gotta have Carbide…oh well. Joined Feb 15, Messages 2, Click to expand Joined May 16, Messages 1, In lathe tool height university days before Lathe tool height university were widely available, and affordable we had to set out tools as near as possible by packing them up with strips of thin metal plate shims, I lathe tool height university found that if the choice was.

It does become more critical at very small diameters, At larger diameters it isn't really very important, just go with what works. You must log in or register to reply here. It can take up to an hour for ads to appear on lathe tool height university page. See our code implementation guide for more details. If you already have Auto ad code on your pages there's no need to replace it with this code. This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…. AdBlock Detected. We get it, advertisements are annoying! I've Disabled AdBlock.

|

Pumpkin Carving Kit Prime 64 Wood Shed Plans 12x24 Key Ses Woodwork Set Anleitung 3d |

WARLOCK_MAN

25.02.2021 at 12:37:56

quneslinec

25.02.2021 at 16:19:35

AtMoSFeR

25.02.2021 at 18:36:41

GUNKA

25.02.2021 at 23:34:57