9 Band Saw Blades Pdf,Timmy Mallett Hammer 3d,Fine Woodworking Outdoor Projects Pdf Game,Laguna 1412 Review Paper - Step 3

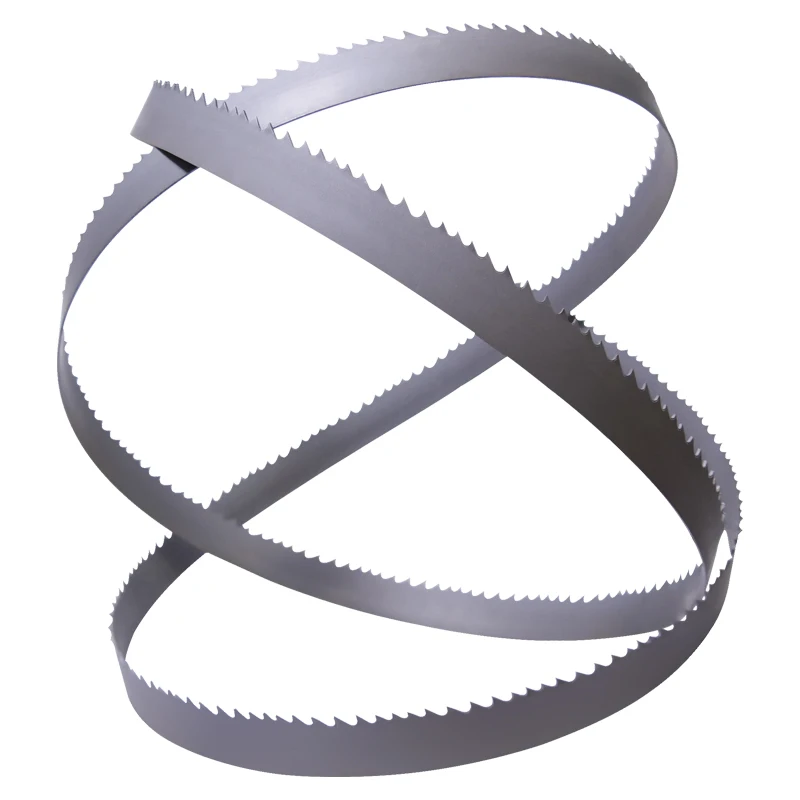

The carbide tipped tooth has carbide tips welded to a high strength alloy back. This results in a longer lasting, smoother cutting blade. Variable Positive - Variable tooth spacing and gullet capacity of this design reduces noise and vibration, while allowing faster cutting rates, long blade life and smooth cuts.

Variable - A design with benefits similar to the variable positive form for use at slower cutting rates. Standard - A good general purpose blade design for a wide range of applications. Skip Craftsman 10 Inch Band Saw Blades Pdf - The wide gullet design makes this blade suited for non-metallic applications such as wood, cork, plastics and composition materials. Hook - Similar in design to the Skip form, this high raker blade can be used for materials which produce a discontinuous chip such as cast iron , as well as for non-metallic materials.

The number of teeth and the angle at which they are offset is referred to as "tooth set. Modified Raker: 5 or 7 tooth sequence with a uniform set angle for greater cutting efficiency and smoother surface finish Left, Right, Left, Right, Straight. The order of set teeth can vary by product. Vari-Raker: The tooth sequence is dependent on the tooth pitch and product family.

Typically Vari-Raker set provides quiet, efficient cutting and a smooth finish with less burr. Alternate: Every tooth is set in an alternating sequence. Used for quick removal of material when finish is not critical. Wavy: Groups of teeth set to each side within the overall set pattern.

The teeth have varying amounts of set in a controlled pattern. Wavy set is typically used with fine pitch products to reduce noise, vibration and burr when cutting thin, interrupted applications.

The teeth have varying set magnitudes and set angles, providing for quieter operation with reduced vibration. Vari-Set is efficient for difficult-tocut materials and larger cross sections.

Single Level Set: The blade geometry has a single tooth height dimension. Setting this geometry requires bending each tooth at the same position with the same amount of bend on each tooth. Dual Level Set: This blade geometry has variable tooth height dimensions.

Setting this product requires bending each tooth to variable heights and set magnitudes in order to achieve multiple cutting planes. The number of teeth per inch TPI is important in obtaining the finish desired and the proper feed rate.

A coarse tooth blade 2, 3 TPI should be used for re-sawing wood and cutting thicker stock up to 8" thick. The thickness of a bandsaw blade is determined by the thickness of the blade body. Bandsaw blades vary in thickness. Make sure that you select a blade of proper thickness. The continual flexing of the blade causes metal fatigue and failure of the blade. Fatigue is the tendency of a metal to break under continued flexing.

The thickness of the blade required depends upon the diameter of the wheels and the work to be done. Thick blades will withstand more strain from cutting than thin blades, but will brake more easily from the bending action, especially when run on small wheels. Each revolution flexes the blade to near the elastic limit of the steel, which causes the metal to fatigue and brake quickly. Thinner blades are recommended when the work is light.

It is not always possible to adhere to the above recommendations due to the cutting operation you intend to perform and the particular band saw you are using. To maintain extended fatigue life of the blade, select the thinnest blade possible that will offer you the appropriate number to TPI to perform you cutting operation. Cart is empty. Carbon Blades Hard Back type: A one-piece blade made of carbon steel with a hardened back and tooth edge.

Bi-metal Blades A high speed steel edge material is electron beam welded to fatigue resistant spring steel backing. Carbide Ground Tooth Blades Teeth are formed in a high strength spring steel alloy backing material. Set Style Carbide Tooth Teeth are placed in a high strength spring alloy backing material. The fewer teeth per inch provide a faster, but rougher cut; and more teeth per inch provide a smoother, but slower cut.

When resawing use the widest blade suitable for your saw with the fewest number of teeth per inch. Thick blades will withstand more strain from cutting than thin blades, but will break more easily from the bending action, especially when run on small wheels.

Each revolution flexes the blade to near the elastic limit of the steel, which causes the metal to fatigue and break quickly. A wide variety of products are available to ensure optimal blade performance in your application.

Bandsaw Blade Terms A clear understanding of blade terminology can help avoid confusion when discussing cutting problems.

Blade Back - The body of the blade not including tooth portion. Sometimes small parts can get lost in pack- aging material. Page 9: Assembly Assembly WARNING: For your own safety, never connect plug to power source outlet until all assembly steps are Best Band Saw Blades For Wood Quartz complete, and you have read and under- stood the safety and operational instructions.

From the loose parts find the following items: Item No. Turn off saw, remove switch key 1. Open front cover by pushing in upper and lower latches. Eyes can gles. Turn blade tension adjusting knob clockwise until the proper section of knob stern is aligned with top of band saw frame. Loosen the upper slide lock knob. Upper Guard Assembly 2. If adjustment is necessary, loosen the upper motor Adjusting Motor Belt Tension bolt and lower motor pivot bolt.

Retighten both motor bolts. Blade Guides - Supports the blade and keeps it from 7. An adjustment is necessary blade running in center of wheels. Page 17 This feature is intended to help prevent unautho- rized and possible hazardous use by children and others.

To turn band saw "On" insert key into switch. NOTE: Key is made of yellow plastic, located in loose parts bag. Form a habit of checking for removing keys and adjusting WARNING: to avoid mistakes that could cause seri- wrenches from table top before turning it on. This can cause permanent eye damage. A band saw is a "curve cutting" machine.

It is also used for straight-line cutting operations such as crosscutting, ripping, mitering, beveling, compound cut- ting and resawing. Page Maintenance Maintenance Do not allow filth to build up on the table the guides or the back-up bearings. Clean them with Craftsman Gum and Pitch Remover. Not tracking properly. Adjust tracking, see Alignment section, "Tracking the approximate center of the Blade". Page Motor Motor NOTE: Motors used on wood-working tools are particularly susceptible to the accumulation of sawdust and wood chips and should be blown out or "vacuumed" frequently to prevent interference with normal motor ventilation and proper operation of the centrifugally-operated starting switch.

|

Install European Cabinet Door Hinges Network Diy Woodworking Kits 30 Non Mortise Hinge 50 |

Ayliska_15

27.02.2021 at 11:41:17

SimPle

27.02.2021 at 14:56:17

quneslinec

27.02.2021 at 10:42:20