Rockler Cabinet Doors Inc,Fein Turbo Ii Review 05,652 Oak Road Barrington Europe - Step 1

Full overlay, partial overlay or inset? Do you want to make the doors yourself, or would a ready-made option be more convenient? Drawings: Reliable measurements are critical, and sketching out your project can help you visualize whether your plan is coming together. Whether you use pencil and paper or CAD software, be sure to account for appliances, plumbing and any other elements that could affect your cabinet configuration.

Materials and cut lists: Figure out what you'll need before you go to the store, and make a list that the final dimensions and number of project parts. You'll save time, money and material.

Hardware: Think about the types of hinges and drawer slides you want. These can affect construction details of doors and drawers. Rockler offers a variety of tools and products to help you plan your project, including the online Woodshop Calculator for designing cabinet doors, how-to books and videos and our custom cabinet door and drawer services.

Once you've got your materials, it's time to make some sawdust. You'll need to transform those sheets of plywood and boards of solid wood into the final pieces of your project. Here are a few important considerations as you cut and shape the parts for your cabinets. Get organized: Follow your cut list, checking off items as you go, and machine parts in groups to minimize the number of setups. Straight cuts: If you're using a table saw, make sure the fence and miter gauge are calibrated.

If you don't have a table saw, use a track saw system or a circular saw with a straight-edge guide to make sure the cut doesn't wander when dimensioning plywood. Door-making router bits: You'll need these specialty bits and a table-mounted router to cut the profiles on the rails and stiles of your doors and to shape the center panel.

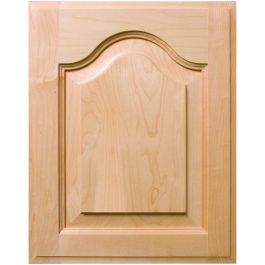

A variety of profiles is available, so you can get the look you want. Door templates: If you're making doors with arched or cathedral-style panels, you'll need to use some sort of template to guide the router bit when shaping the curves.

You'll find everything you need to machine and rout your cabinet parts at Rockler: table saws; track saw and other cutting systems; a wide selection of rail-and-stile and panel-raising bits; ready-made templates for arched and cathedral-style doors; and bits and jigs for making trim and crown moldings. Now's when you can really see your project begin to take shape.

And, no, you can never have too many clamps. It's the moment of truth, time to assemble all the different pieces you've machined into the cases and doors and drawers that make up your new cabinets. Here's what you need to think about for this step:. Glue: Different types of glue are available with different drying times, from traditional yellow wood glues to specially formulated cyanoacrylate super glues to polyurethane glues.

Pick the glue best suited to your application. Glue applicators: You've got to spread that bead of glue you lay down.

Some folks use "acid" brushes, but some prefer new silicone glue brushes because dried glue peels right off, making cleanup easier. Specially designed glue paddles are available for getting glue into tight spots, such as dovetails or box joints. Fasteners: How are you going to secure the pieces together? Pockets screws? Floating tenons? Choose the joinery method that fits your skills and application. Clamps: You'll need a good number and variety of clamps while gluing up your cabinet components — parallel or bar clamps for the case and doors along with clamping blocks to hold door assemblies square ; three-way face clamps for attaching a face frame to the case; pocket-hole clamps for assembling a face frame with pocket-hole joinery; edge clamps; and maybe even band clamps, depending on how you make your drawers.

Rockler has a full selection of products in these categories, including a line of easy-to-clean silicone glue tools; a wide variety of fasteners; doweling and BeadLOCK joinery jigs; and many clamping innovations like our award-winning Sure Foot Bar Clamps.

Advances in technology make it possible for most do-it-yourselfers to achieve a professional-quality finish. The right finish can make your cabinets really pop.

For many people, though sanding and finishing can seem like a complicated, scary process. Here are a few things that can make it go more smoothly and successfully:. Sanding tools: Power sanders especially random-orbit sanders can speed up your surface prep, but there also are sanding blocks and profiled sanding guides for those who prefer elbow grease to electricity. Specialty sanding products are available for detail work and hard-to-reach areas. Sandpaper: You need high-quality sandpaper in grits ranging from or up through or Sand with the grain; don't skip grits; and be sure to clear the surface of dust between grits.

Stains, paints and topcoats: You've got a few choices to make beyond color. Paint, dye or stain? Waterborne or oil-based? Should you apply a sanding sealer first to avoid blotching? What kind of protective topcoat do you want? They can spray a variety of finish types and leave an even surface free of brush strokes. Building your own cabinets also gives you the design control to create a kitchen that will work best for your needs. The type of cabinets that you build will depend on your style preferences, the tools you have and your skill level.

No matter what type or style of cabinet you choose to build, the rewarding process of building your new kitchen cabinets is sure to involve many interesting woodworking techniques and tools. Learn a brief history of modern cabinet construction and the benefits of designing and building your own cabinets. Learn how to install most types of side-mounted drawer slides using the Universal Drawer Slide Jig. Building Kitchen Cabinets.

Building Kitchen Cabinets Building kitchen cabinets is a great opportunity to apply your woodworking skills, learn new techniques, add value to your home and make the time your family spends in the kitchen more enjoyable.

|

Best Rap Songs 1999 Qt Cnc Machine Bits 20 |

Samurai_0505

21.02.2021 at 19:50:52

elcan_444

21.02.2021 at 22:48:10

karizmati4ka1

21.02.2021 at 10:51:44

454

21.02.2021 at 16:57:24

sevgi

21.02.2021 at 13:36:44