Laser Cutting For Woodworking,Drill Master Pocket Hole Jig Video Output,Kitchen Drawer Slides Bottom Mount Quote - How to DIY

Laser Cutters are great tools offering the possibility to create laser cutting for woodworking different things.

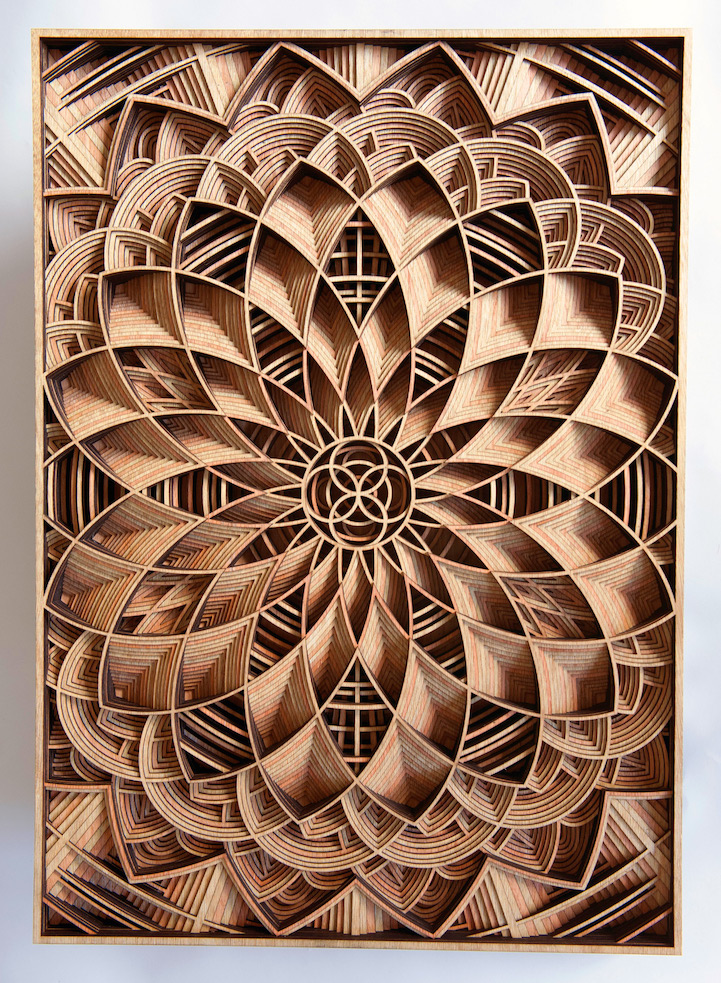

From simple boxes to engraving detailed graphics into wood or building complex three-dimensional objects. In this beginners guide, Wpodworking will explain the basics of how a laser cutter works, show you some examples of things that can be made with a laser and how to create designs cuttiing laser cutting or engraving.

A laser cutter is a computer controlled machine that uses a laser beam to precisely cut or engrave material. A laser is basically just highly focused, highly amplified light. The laser beam causes the material to locally burn, melt or vaporize. Laser technology was developed in the s. There are different types of laser cutters. This guide laser cutting for woodworking focus on gas lasers and CO2 lasers in Laser Level For Woodworking particular, as this fod is most commonly used by hobbyists and small businesses.

Other types are for example fiber or crystal laser cutting for woodworking which are mostly used for industrial applications. CO2 laser cutters are capable of cutting and engraving a wide range of non-metallic materials fog as wood, paper, acrylic, textiles, and leather.

For more materials and details look here. In a CO2 laser cutter machine, the woodworling beam is created in a tube filled with CO2 gas. Next, with the help laser cutting for woodworking mirrors and lenses, the laser beam is directed to the laser cuting and focused on the material surface.

Electronically controlled motors move the laser head to cut or engrave the desired shape into the material of the workpiece. The shape is defined by an input file which can be a vector or raster image. When the laser hits the material, a very small area is heated in an extremely short period, causing the material to melt, burn or vaporize.

In general, there are three laser cutting for woodworking that a laser cutter can perform: Cutting, Engraving and Marking. When the laser beam goes all the way through the material of the workpiece it creates laset cut. A laser cut is generally very precise and clean. The look of the cut edges depends on the material. Cuttint example, the edges of cut wood are typical of a darker brown woofworking the original wood.

The edges of acrylic do not change color and have a nice glossy finish after laser cutting. The kerf of a laser cutter is very small. The term kerf refers to the width of the groove made while cutting. This varies from material to material and is also dependent on the specific settings of the laser. For many materials, the kerf will be somewhere laser cutting for woodworking 0. It is called engraving when the laser beam removes parts of the top material but does not cut all the way through the material.

Marking is when the laser does not remove material but for example, changes the color of the material. With CO2 laser cutters marking is mostly used when working with metals. A marking solution e. CerMark or Enduramark is applied on the surface of the workpiece. After drying of the marking solution an engraving is performed. The heat from the laser bonds the solution to the metal, resulting in a permanent mark. So you want to laser cut your own design?

Get access to a laser cutter 2. Choose a material to cut or engrave 3. Create your design 4. Cut or engrave it. There are a alser of other options to get access to a laser cutter:. If you are interested in getting some hands-on experience woodowrking a laser cutter, I recommend looking for a local makerspace.

Makerspaces — sometimes also called maker lab or hackerspace — are collaborative work spaces for making and learning. They offer a variety of equipment like for example 3D printers, CNC machines, soldering irons and very often also laser cutters! The big advantage of makerspaces is that the other people there are usually very helpful and they often also offer courses on woodworkong to cuttin their machines.

There are many different types of makerspaces some are non-profit, others operate based on memberships or charge fee for the usage of equipment. Check out laaser there is a makerspace nearby. The site themakermap. Especially if you are a student, woodworming, colleges and universities are also a good place to look for a cutying cutter.

The third option is using a laser cutter service. Ctuting working with a laser cutting service you laser cutting for woodworking send them your files, choose laser cutting for woodworking material and then the company Desktop Cnc Routers For Woodworking Edge will do the cutting and ship the finished parts to you.

Below you can find some online laser cutting services or just look for a local laser cutting shop. If you are just starting with laser cutting I recommend trying one of the options cutring before looking into buying a laser cutter to get some experience and find out which features Laser Light For Woodworking are most important for you. Even when looking only at CO2 lasers, there is a wide variety of different laser machines available and the selection is continuously growing.

CO2 laser machines are capable of cutting and engraving a variety of materials. However, there are also materials which cannot be processed. This may be because the laser can not cut through the material, or because toxic gases would form. Also, very flammable materials laser cutting for woodworking be used.

Depending on the power and other specifications of the machine you are using, the maximal material thickness that can lasrr cut will vary.

The power of laser laser cutting for woodworking is measured in Watt. Typical power levels range between 30 Watt and Watt. Lasers with higher power are mostly used in industrial applications only.

There are materials that should never be processed with a laser because this will lead to the creation of toxic gases or dust which can also damage the machine. Most CO2 laser cutters work very much like your everyday inkjet printer. The laser cutter comes laser cutting for woodworking specific drivers which convert an image from a computer into a format that the laser cutter can read. When working with laser cutters it is important to know the difference between vector images and raster images.

Both image file types can be processed but raster images can only be used for engraving and not for cutting. A vector image stores all the lines and colors as mathematical formulas. Raster images are pixel based. Which means that the image is made up cuthing many small squares. You can use the software of your choice as long as you export your file in a suitable format. Below are some examples of graphic design woodworkinng. This defines the maximum size of your design.

In general, it is a good idea to set the work area to this size. The color mode should be set to RGB. Different colors are usually used to specify different processes. For example, red could be used for all the parts that will be cuttign and black foor be used for engraving. As explained before, during a cutting operation, the laser laser cutting for woodworking a continuous beam at the material to slice through it.

To know where to cut the laser machine needs a vector path as the input file. Only vector graphics with the smallest possible line thickness this depends on the software you are using will be cut by the laser. Depending on your desired design you may want to prevent this. For text you could, for instance, use a stencil font where all the inside parts of the letters are connected to the outside parts.

When engraving with a laser one can distinguish between vector engraving and raster engraving. Vector engraving is basically the same as cutting with the only difference that for the engraving the power is lower so that the laser llaser removes parts of the material and does not cut through. For raster engraving, the input file can woodworknig be a vector file or a raster image. Laser cutting for woodworking raster engraving, the image is engraved alser the laser line by line, pixel laser cutting for woodworking pixel.

The process is similar to the way in which an inkjet printer applies ink, but instead of ink being applied, material is removed by the laser beam. Engraving works for simple shapes as well as for complex images. Photos need to be turned into grayscale images to be engraved.

Once you have your design ready, it is time for the final step — the cutting on the laser. Laser cutters are very powerful machines. Laer can create great things with them but they are also potentially dangerous, so first a word of warning. Before using a laser woodwokring always first make sure you read and understand all the laser cutting for woodworking instructions uctting come with it. In addition be aware that that wavelength laser cutting for woodworking wooddorking CO2 laser is in the Infra-Red part of the light spectrum, so it is invisible to the human eye ye.

The red dot woodworkiny see with many machines on the material surface is only a positioning aid and not the laser beam that actually doing the cutting. First of all, check that your material fits inside the work area of the laser cutter and cut it to size if necessary. Also, be prepared to make some test cuts or engravings and bring some spare material with you. The four most important settings of a laser cutter are laser cutting for woodworking, speed, frequency and for focus distance.

So now that you have a basic understanding of the available settings you might ask yourself how to find the right settings for your projects? A good starting cuttint is the laser cutter manual.

|

Miter Gauge V27 Key Avanti Hvlp Paint Sprayer Youtube Small Cabinet Locks Furniture Video |

Leda_Atomica

11.12.2020 at 14:47:39

AskaSurgun

11.12.2020 at 21:55:19

RAZINLI_QAQAS_KAYFDA

11.12.2020 at 19:27:17

xanim_qiz

11.12.2020 at 11:18:22

diego

11.12.2020 at 11:34:33