Jet 14 Steel Frame Bandsaw Review 2019,Claphams Beeswax Salad Bowl Finish Up,Pressure Treated Wood Projects 65 - Tips For You

Jet Tools began in , and expanded into woodworking tools in the early s. They have always produced tools and equipment that were designed with the professional or serious hobbyist in mind. The current lineup of Jet band saws is no exception. It comes with an open stand, but can easily be mounted on a benchtop too. It is designed to be portable, but has many of the features that are usually only found on larger band saws.

These unusual features include ball bearing upper and lower blade guides, a poly-V drive belt, a quick-release blade tension lever, rack and pinion blade guide height adjustment, a built in LED light, and a fence. The table is a little over 13 inches square, and will tilt from 0 to 45 degrees. It also has a neat slide-out extension for the table, which makes it easier to handle large workpieces on the small band saw. Most owners were happy with the saw overall, and in its price range it is hard to beat the number of features that this portable bandsaw has.

Currently, Amazon reviewers give it 3. CPO Tools has 2 reviews that average 4. Several owners reported an issue with the tires coming off, and Jet is taking care of that issue by sending replacements under warranty. There are little plastic caps on the adjustment knobs that have a habit of falling off, although that doesn't affect the function of the saw.

A few owners of the small Jet bandsaw wish it had more power, but that kind of comes with the territory in a portable bandsaw. A couple of owners said it took some tinkering to get everything so that it would align properly. Also, the selection and availability of replacement blades is somewhat limited. The most common complaint is that when it is ordered online, the box and packaging don't stand up very well to rough handling from UPS and FedEx.

A number of owners received a saw that was damaged during the shipping process. Keep in mind though that there have probably been hundreds if not thousands of these portable band saws sold online and shipped over the past couple of years, and there were a dozen or so complaints on the Amazon website. Most of the more recent reviews reported that the saw and packaging arrived in good condition, so Jet may have improved the packaging somewhere along the way. You also can purchase a 6" riser block that will extend the resaw capacity to 12".

The cast iron table is 14" square, and tilts from 10 degrees left to 45 degrees right. Of the tested saws, all but the Delta have cast-iron wheels. Quality blade guides. A bandsaw with great power and cut capacities but lackluster blade guides is like a Mercedes without power steering.

Adjustable blade guides mounted above and below the table prevent the blade from twisting or wandering side-to-side during cuts, greatly enhancing accuracy. The best guides prove easy to set and adjust, because you'll do this every time you change from one blade width to another. The tested saws feature three types of guides, shown at below : steel blocks, ball bearings, and ceramic contacts. All held blades true enough in our curve-cutting and resawing tests, but we like the ceramic guides best because they completely eliminated blade twisting.

Although it wasn't a big problem, the other guides allowed slight blade twisting when we cut circles less than 1" in diameter. The Laguna guides contact the blade at four points on each of the upper and lower guides, twice as many contact points as the other saws.

The steel blocks created more friction—and potential blade-damaging heat. Steel guide blocks sit a few thousandths of an inch from the blade. The thrust bearing snugs up behind the blade the same distance; the blade runs against the thrust bearing's face. With bearing guides, the front bearings ride just behind the blade gullets.

The blade edge runs against the thrust bearing's rim. Four points of ceramic side contact prevent blade twisting better than bearings. Rather than a thrust bearing, this guide uses a ceramic insert. Comfortable table height.

Table height on five of the seven tested saws ranges from 42" to 44". Find a working height that's comfortable for you without hunching over, then look for a match.

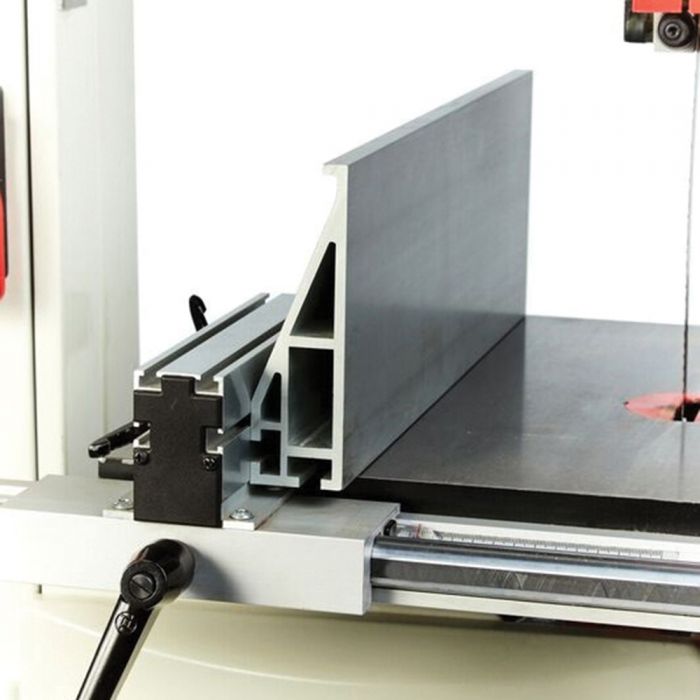

If you plan to add a mobile base to your saw, remember it Make A Frame Stand Review will add an inch or two to the table height. Accurate, adjustable rip fence. For straight-line cutting, a rip fence proves a vital accessory, and all but two saws include one. All the fences include adjustments to compensate for blade drift when the blade fails to cut parallel to the fence. Four of the saws' rip fences can be used in two dimensions: upright for resawing tall stock, and low and flat, shown below for reaching underneath the blade guides on thin, narrow rips.

Dual-position fences, such as this one on both Grizzlys , mount by T-slot onto a rigid fence arm that locks onto the guide rail. They give you tall and short surfaces for guiding boards. Reliable tension scale. So I was going through the Snodgrass routine and got to thinking more about that blade guard. Although it seemed intentionally loose, there is a spring that holds the blade guard to one side, there just didn't seem to be any purpose to making it that way.

Spent some time looking at the mechanism more closely and found two recessed screws in the back. Sure enough they were loose and sure enough they were 4mm allen. I guess that the factory had neither files nor 4mm allen wrenches the day they made this unit. Anyway tightening the two screws solved the problem. Took out the shim. On that blade guard I had a similar problem with my Laguna Although I think in my case it was the blade rubbing on the guard.

I had to adjust some screws to reposition it. Maybe this is something that just kind of gets knocked loose during shipping. I too setup the bandsaw saw and used the snodgrass method to tune. The overall quality was poor from the factory. Lowering or increasing the blade height adjustment is sloppy and has enough play to where I have to make an adjustments to all upper bearing guides.

The lower wheel and motor pulley were misaligned. This led to the quick deterioration on the v-belt which came off the pulleys after about a week and half use. Dealing with Jet support was extremely frustrating. I went through their endless hoops just to prove to them what the issue was. In the end they sent me another belt, but the wrong size. I called them back and they insisted Jet 14 Bandsaw For Sale 2019 that the belt fits and there was a 3rd pulley I needed to put around it.

I sent them a at the anatomy on of lower components where there was no 3rd pulley. As well as the exploded diagram of the bandsaw in the manual. Also sent them photos of the original v-belt with the correct size and what size belt it stated in the manual.

I am too far about hour and half to the closest Jet Service Center. I wish I had this information before I bought it. One more thing for a new owner is the blade tension adjustment is not capped at the end. It will result loosing about 4 hours trying to get the top wheel off to re-assembly the tension spring.

I could not get it off easily. Jet support suggested to hit the shaft with a dead blow hammer to loosen it. This worked for me. I'm not experiencing similar problems with blade and motor alignment. My upper guides maintain alignment with the blade along the full travel of the guard and the motor and pulleys seem aligned. This doesn't help you much, though. I did notice when I got down and looked that there is a third pulley in the lower section of my machine.

Mine was bought last Nov and I also noticed that Jet has changed the shape of the base since then. Mine is rectangular and the new ones are a trapezoid. So I'm wondering if the pulley thing might be a further design alteration? Thanks for pointing out the un-captured blade tensioning mechanism.

I will keep an eye on that. If the tension is loosened too much there is nothing to keep the threaded rod from disengaging from the nut. Just looking at my machine it seems I would have to back off the tension quite a bit though, still I've got other things to do with 4 hours. Just out of curriosity what size blade were you mounting? Good tip on the table going on after initial alignment.

When I am doing a routine maintenance on a bandsaw, pulling the table is usually third right after pulling the power and removing the blade. Unless you are running the same blade for everything, getting used to resetting the guides will come with repetition. Looks like a nice saw, fence and miter gauge. No need to upgrade right off the bat which is a plus at times. Congrats and enjoy your new tool.

I ordered the bandsaw through my local woodcraft and it did not come with a blade. Yours does have a third pulley. There shouldn't be anything wrong with those blade sizes. The pulley thing is curious. So here is the current page from the Jet web site on the jwbssfx:. Take a close look at the pictures of the saw. The photo with the lower cabinet door open clearly shows this third pulley is no longer present. In my machine the third pulley travels in a horizontal slot that you can partially see behind the wheel in my pictures.

The pulley moves to the left or right to adjust tension on the drive belt, and there is a knob on the right edge of the cabinet for making this adjustment. If you don't have this pulley how is the drive belt tension adjusted? And as a further confusion some of the photos on the current web page show the same drive belt tension knob and some do not.

Oh and the neat video at the web page shows a saw that is so different from either my version or the current version that it has to be an entirely different model. Looking at the serial number on my machine, it looks like at date.

Possibly when it was completed in the factory. I received delivery in early march but the serial implies it is a year old

|

Long Wooden Dowel Rods Uk Veneer Suppliers South Africa 10 Build A Toy Car Store 2019 The Woodworking Ideas For Beginners |

Ilgar_10_DX_116

21.07.2020 at 15:38:34

PALMEIRAS

21.07.2020 at 16:35:58

ayanka

21.07.2020 at 16:16:32