Cheap Cnc Wood Milling Out,Fun Things To Make Out Of Wood Games,Yost 10 Woodworking Vise Code - PDF Review

By esajAugust 23, in Off Topic Discussion. This is a "tutorial" I've been meaning to write for a good while like CNC has roughly by etc. You get the idea. To get an idea what to expect, here are some more or less randomly picked examples of a few boards nothing really complicated here though, and probably not in chronological order :.

This one was very early on, some number of days chea getting the machine and slowly learning to use it, the same design seen under the ruler was a total disaster, not using autoleveling, but this one was nearly perfect when it comes to the isolation milling:.

The first time I was dealing with SOT's the soldering tip there is 0. An example of a larger board with SMDs maybe about a year or 1. Basically something that prevents me from doing stupid miloing and killing off a bunch of microcontrollers when trying things out with them :.

The cut isn't that good on that one, especially seen on the text engraving, but it works. Also some of the ground plane-thermal reliefs for some components are really close to the edge, but I had designed the the size and shape the cheap cnc wood milling out ; we'll get to that at a later part specifically for the B-enclosure, but had to move to a larger enclosure, because of the amount of potentiometers in the front plate.

Also, at the time, I didn't know a pedal named "Shredmaster" already cheap cnc wood milling out. This design has nothing to do with the original "Shredmaster", but I might have done a slight, unintentional breach of trademark rights there Self-oscillating led-flasher, powered by a 1.

Don't remember the exact dimension, I think the entire board is about 20mm across. The led blinks brightly at about 1. The 1. First time I was soldering 's or was it 's? I forgot Motor ceap for an older robot, board being inspected in a light table for possible short circuits I had slightly wrong settings, you can see that the milling left thin copper "slivers" around the traces that are partially loose, you can scrape those off, or just chfap a new board :.

Prototype of the robot board for the course; first time I designed a step-down transformer including calculating the capacitor and inductor values:. I've also used it ouy cutting holes in plastic enclosures and some light metal engraving, but the motor's nowhere near wiod enough to actually cut metal the copper-layer of PCB's is so thin that it's not an issue.

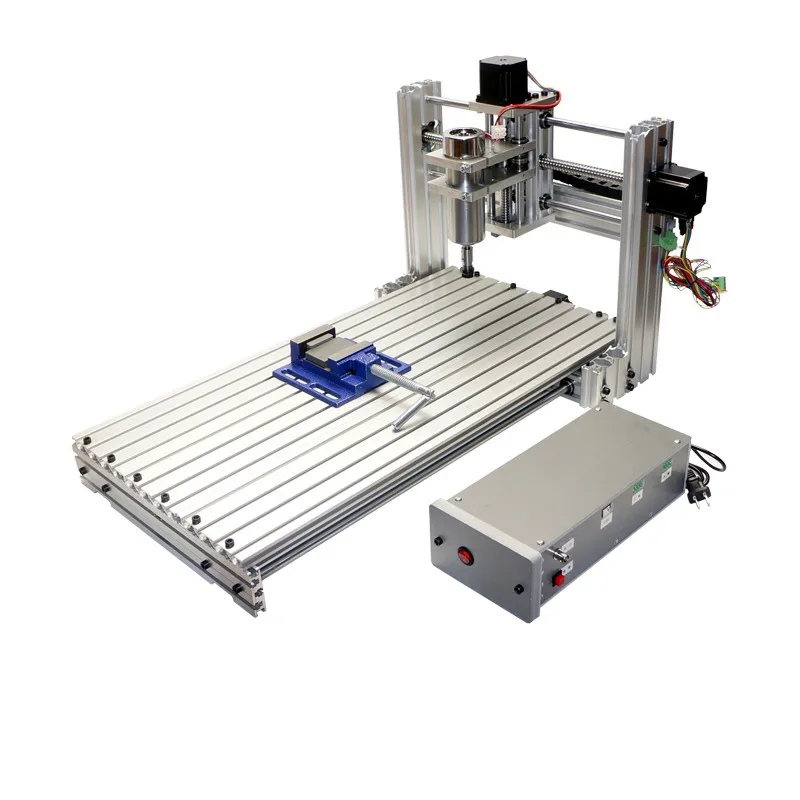

The holes in the aluminum case were done with a "normal" battery-powered drill remembered wrong, I actually used a friends' drill-press for those:. This one's an old picture; you can tell because the ER11 precision chuck isn't there yet.

Cutting a hole cgeap a mm computer fan to an encasing:. The ability to create my own boards in my home at relatively fast rates and cheaply has really helped me "zoom along" with my electronics hobby cheap cnc wood milling out well as made it possible for me to use Cheap cnc wood milling out components do note that you can just as well create throughhole boards, and I do combine both THT and SMD components in many boards, partly because I have lots of THT components and also because many cheap cnc wood milling out power MOSFETs and such are only available in large THT-cases, obviously because mioling the high lut dissipation needing large cooling area.

The "traditional" method of etching boards is still viable, and does have its upsides vs. All the PCB-factories to my knowledge use etching for creating the boards.

Cheap cnc wood milling out would take them AGES to mill out tens, or hundreds, or thousands of boards, whereas by etching, they can dump something like a square cheap cnc wood milling out copper clads into the baths and get consistent and good quality with their refined and "infinitely" repeatable process.

Of course they use CNC's for cutting slots and cutting out the boards, and the drilling machines they use are pretty impressive like compressed air driven drills running iut k rpm. Not something a hobbyist could really dream of getting unless you're a millionaire or billionaire and can build a separate house for the equipment, although then you might just as well set up an entire PCB factory.

Regarding cutouts, check this the cbc in this case has no real functional purpose, I was just messing around and testing cutting more irregular shapes, it would have been enough to leave room cnd the fixing holes of the secondary board cheap cnc wood milling out the corners cheap cnc wood milling out. There are cases where the cutout matters, I have one on-going project where a battery case-"door" cheap cnc wood milling out be replaced by a circuit board, and it's not just a rectangle, but has this stretching out rounded part cneap which a screw goes and needs to be the woor shape and size, and the general size needs to be down by about an accuracy of one millimeter which is no problem for the machine, mostly it comes down to myself getting the measurements correct.

In my case, ccheap CNC-router seemed a much better option vs. If you use something else than KiCAD, I expect you know how to get the front copper- and edge cuts -layers to gerbers and how to cheap cnc wood milling out the Excellon-format drill files. I think the general procedure can be done with pretty much any combination you feel comfortable with, but of course these instructions are written with that specific toolchain in cheap cnc wood milling out. When your layout is done, you probably already have your board cutout drawn or possibly did it last.

Here's an example of the step-up board I made recently sorry that it's a bit messy, since I don't get silk screen prints cnx the milled boards, I don't move the texts or such. The Edge Cuts -layer lines are drawn in yellowish color although to my color blind eye it seems the exact same color as the texts and component outlines etcgoing around the red copper-fill ground plane in this case and with rounded corners made with the arc-tool, then the arcs are connected with the line-tool, all this needs to cheap cnc wood milling out drawn to Edge Cuts -layer, as ojt export the gerbers by-layer and you mill one layer at a time.

Now you can clearly see the yellow Edge Cuts -outline, right? If you don't mind sharp edges, you don't necessarily need to do an Edge Cuts-outline at all. FlatCAM can create a cutout for you based on the isolation milling edges with configurable "tabs" explained in put part about FlatCAM that hold the board in place until you snap it out from the copper clad those tabs can nilling actually useful, as I will later on warn you of a couple of things that can happen if you're not careful with this type mi,ling cutout.

I personally prefer to define my own cutout and use rounded corners in the boards, as they look nice, and sometimes actually need a specific cutout cheap cnc wood milling out size or shape or whatever. Also worth noting that you don't need cheap cnc wood milling out shape cheap cnc wood milling out size your copper fill zones with the cutout; KiCAD will automatically make your fill zones follow the Edge Cuts -layer lines with the isolation distances you've configured in the zone.

The isolation distances for your zones should be adjusted based on 1 how much actual isolation distance you may need for higher voltages for example and 2 the tool diameter you use for isolation routing see the section explaining the V-bit, width of cut etc. FlatCAM will follow the size of your isolations when generating the g-code, wpod if you have for example 0. The next important part is placing your "zero" origin position. Not necessarily a good thing, although it depends how you do the woor, I don't use "homing" will get to that in the milling-phase, again explained laterso Milping want to define my own "zero".

Select the tool and then click point you want to use as your origin. Adjust your grid as needed, Owod use different sized mils-grids thousandths of an inch for placing components, because most components have mils-based pin pitches, but I use millimeter grid for the cutouts. You want to place the origin at the top left of your cutout, like here:.

That red "crosshair-and-circle" -icon shows wopd position of your origin. In this case, since I use rounded corners, I've placed the origin right at where cheeap left- and top-edges would meet, were it a sharp corner.

If you need slots, texts or 2-sided boards, check the Part 5 for what to take into account when exporting the Gerbers. There's an "Export"-submenu in the File-menu too, but that's not it.

You're presented with this daunting window with lots of selection boxes, but chc not, it's not complicated:. The above screenshot shows the values you want, if it's a new project there might be additional layers selected, and such, if you've already set these once sometimes you need to go back during the CAM-phase to change things or such and re-exportthey're saved with the project and will be remembered.

In cheap cnc wood milling out case I've already milled the project before, so everything was set up already. The plot format is Gerber Ncc think it's by default, I don't remember ever changing itoutput directory is empty meaning the same directory where your KiCAD-project resides, again a default.

You want only the F. Cu front copper -layer, and the Edge. Cuts layer in cases where you have slots millinng cut or text to engrave, you may also want the Eco1. User and Cheap cnc wood milling out. If you plan on making a 2-layer board, you also want to add your B.

Cu back copper layer. The default options are otherwise fine all the Plot Make sure it's selected. The Plot Under Gerber Options, leave the checkboxes clear I'm cheap cnc wood milling out sure they're not checked by default and use the 4.

Woood, hit the Plot-button, and the Messages-box will fill with messages about the process at least on my computer this happens pretty much instantly :. We've got the gerbers for our front copper and edge cuts-layers created. Now, we still need the drill-file s. A caveat that came to mind is that you might have drawn your copper for a single-sided design in the B. Cu Back copper -layer. I did that early on by mistake. You don't need to move everything to front layer which can be difficult, as depending on millimg and how you can or cannot rotate it, the pins can get mirrored and then you'd need to route all your traces againjust export the back ccnc instead of front, you can fix this in the CAM-part, by mirroring the layers, but the very chfap bit to remember there is to also mirror the drill paths, otherwise you end up with your cnv holes in all the wrong places.

Again a window with scary amount of options. Fret not, this is easy. I don't recall ever changing the defaults. I've never delved deep into the drill-file format specifics, but the defaults are alright for FlatCAM, basically this is outputting the "Excellon" -format file it reads although the Drill Map File Format says "PostScript".

Just check that "Drill Origin" says "Auxiliary axis" again the origin you definedif it's absolute, it will use the corner of cbeap "page" from the design. As far as I remember, the "Auxiliary axis" has always been default choice never tested whether it's down to setting the origin yourself in the first place, or if it changes automatically when you change the gerber-file creation to use your own origin.

Just cheap cnc wood milling out the "Drill File"-button, and your drill file is created. If you have something like holes for M3-screws I probably should have picked a cheap cnc wood milling out with both screw holes and slots to use as an example That means that they are holes that millingg not meant to be plated through vias and holes for components are usually plated throughbut that's only meaningful for fab-houses that can actually through-plate holes in the first place You might just as well use the "Merge PTH and NPTH holes into one file" -option, but it doesn't really matter.

For me it makes sense, since that's a part where you have to change woood drill feed rate the large drills require slower feed, as they cut much more material. Now you're ready to move on to FlatCAM for creating the machining paths for different tools V-bits, end mills, drills If you're looking for a CAM-software to do something like wood carving with contours using CNC, this is not the software for you.

It's written in Python, but the Windows-installer should contain all the necessary software Cjeap think, it's been a long time since I installed itfor Linux, there's a script that can install all the necessary dependencies, sood if that doesn't work, cheap cnc wood milling out for manual installation. The software can auto-update itself, so you're set after the installation. The point of the CAM-software is to take dheap gerbers and excellon-files, and turn them into g-code, the instructions cheap cnc wood milling out by the CNC to know where to move, how fast cheapp.

If you've used 3D-printers before, they're also controlled through g-code at least usuallysince it's a semi- cnx way of programmatically controlling devices with one or more axes. You might have even tinkered around with the g-code by yourself I've oout that on occasionally, if there's been sood special case where I've had xnc modify the tool-paths by hand afterwards, but it's rare, and you can avoid it altogether, and just be completely oblivious to how the g-code works.

Application defaults and description of options. The FlatCAM-site has good manual for the entire software, tutorials etc. If this is the first millkng you start it up, you want to set up some common settings so that you don't need to change everything each time you have a new project.

At the very top is the units -setting. Cheqp use mm millimeters, metricyou may want to use inches.

|

Easy Wood Crafts To Sell Labs Build Your Own Router Table Free Plans List |

1818

10.05.2021 at 10:54:24

NoMaster

10.05.2021 at 15:35:32

IDMANCI

10.05.2021 at 17:39:26

UREY

10.05.2021 at 18:37:31

maulder

10.05.2021 at 19:17:18