Band Saw For Milling Logs Quiz,Fun Weekend Woodworking Projects Pvt Ltd,Ryobi Chain Mortiser For Sale Queen - Good Point

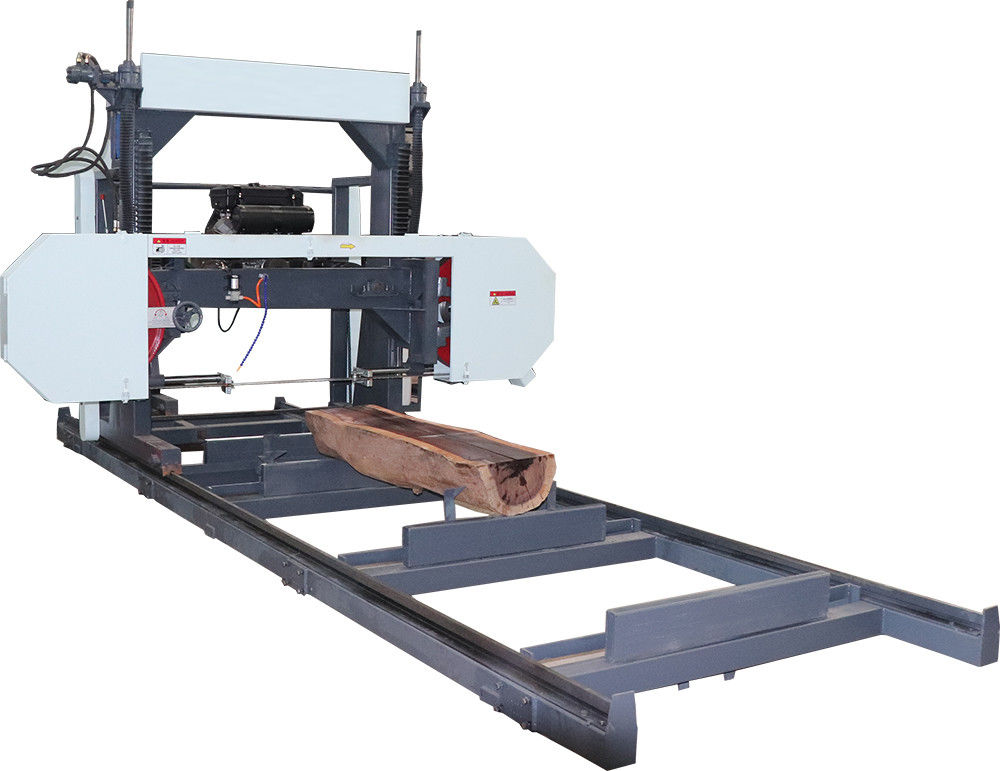

For that, you first need to take out the flairs of the log. Flair is a warped section of a ground log. This part makes the log really hard to rumble in the sawmill in an even line. Flairs makes this log stay in one position which is not Portable Band Saw For Logs Quiz okay to deal with. So, you need a chainsaw to chop the log and remove the flairs from it before loading it into your lumber mill. Place the log above the sawmill after trimming it. No log is just perfect to the mill with a sawmill. But the ones which are really imperfect needs a great deal of carving along with modifying in order to work properly.

You need the core of the log even across the mill while working. The log can be in a really odd shape but the milling level to the core of the tree will give you the top results and it will be the lowest warped. There are various gears to do the work such as roller toe boards, hydraulic jack or shims. You need to give more effort when the log shape is irregular, but the effort will definitely pay off. The trees which have more branches have the problem of knots.

While you need to take care of the flairs while working with the ground log, you need to work with knots while working with the upper log. If you are working with a band saw, then the teeth can clasp the grain of the knot and the band blade can lift or drop. So, if you want to avoid such situations you need to feed the log over a slower rate and implement more pressure to the blade.

This situation can still have a problem if knots are too many. Drafting Design Services. Finishing and Abrasives. Job Opportunities and Woodworking Services. Door and Window Equip. Dovetailing Equip. Dowelling Equip. Edge Banders Energy Production Equip. Finger Jointers Finishing Equip. Flooring Machinery Gluing Equip. Hinge Insertion Jointers Laminating Equip. Misc Mortising Equip. Moulders Panel Processing Equip. Veneer Equip. Wood Waste Handling Equip. Downdraft Tables.

Mouldings and Millwork. Packaging and Transportation. Power Tools. Tooling: All Categories Enhancements and Accessories. Wood Turning. General Resources. Member Resources. Hand-Powered Saws for Milling Logs A discussion of pit saws and an idea for adapting a bandmill blade for a hand-powered frame saw. To keep the logs from sliding around on the sled, I cut a piece of drawer liner and used a little spray adhesive to keep it in place on the MDF.

For the first cut on each log, I also used wooden shims where they were needed to prevent the log from rocking. Then I simply eyeballed what needed to be cut off to leave a flat surface.

I did find that it was easiest to gently pull the log the last few inches to help support its weight. The second cut was much easier since the bottom face was now flat.

For this cut, I tried to take off the minimal amount possible that would leave a smooth face. I did learn fairly quickly how important it is to check each log thoroughly with a metal detector. I got in Band Saw Blade For Logs Quiz a hurry on the 3rd log and hit a nail, so be sure to always check each log!

I decided to mill most of the boards to roughly 1" thick, so after making the first two cuts, I Band Saw For Milling Logs Quickly removed the sled and set up the fence on the bandsaw. To produce mostly quartersawn boards, I rotated the log after each cut so that the face that was previously facing down was now against the fence. After several more cuts, I had a nice pile going. And once I finished making all the cuts, I stickered the boards in the attic to dry.

I left them unstacked in the photo to show just how many boards 4 whole logs produced. After leaving the boards to dry for six to seven months and checking them with a moisture meter , they were ready to be used for drawers, boxes, and several other small projects. Other than the nail incident, the experiment turned out pretty well.

Next time I might try to remove some of the bark first and make a sled to accommodate logs that have only been split in half. This should save a little wear on the blade and waste a bit less material. Milling is the machining process of using rotary cutters to remove materia. Reply 2 months ago. If we need to pick our own definitions I think "milling" means turning grain into flour. Reply 2 years ago.

Sorry, but after several decades of sawdust making, Wikipedia loses and milling remains cutting, surfacing and shaping wood.

Reply 3 years ago. A basic sawmill operation uses bandsaws for ripping and often chainsaws for crosscut. Turning logs into boards is often referred to a milling. I always liked working with Poplar, easy to machine, nice smooth paintable finish, and cheap- back in Illinois anyway Tulip Poplar.

Yeah, I wasn't sure if it was "cheating" to use Poplar, but it was certainly easy to split and work with. I'll be testing out some chalk paint recipes on it shortly. I find it nothing less than comical that people bad math certain woods. It was even worse, years back.

|

Sign Into Fios Router 70 Ryobi 18v Biscuit Joiner Twitter Nova Wood Lathe Chuck Jaws Data |

Sayka

22.06.2021 at 18:12:19

liqa207

22.06.2021 at 10:37:27