Woodshop Layout Design Software,Quick Release Vise For Workbench Ubuntu,Engine Flush Bitog,Cabinet Hardware Drawer Slides Model - For Begninners

In this article we first spftware about the criteria that are important for us when it comes to a free CAD software and then talk about some of the software solutions we are using and their advantages and challenges. At the end we will talk about what software we use for 3D printing, woodworking, laser cutting, and other tasks. The first any maybe most important difference between CAD systems is if you are looking for a 2d model that could serve as a template to transfer to your material or that would enable you to create shapes for a lasercutter or a vinyl plotter — so everything where we have no thickness but only 2 dimensions.

If 2 dimensions are not enough you are looking for a system that can model things in three dimensions so you can plan a woodworking project or create a shape for 3D printing. For CNC work or 3dprinting you will most of the time be focused on an woosdhop part and have less of a focus on the connection between a lot of individual pieces.

In woodworking most of the time you will work with projects that have a lot of parts. This table is a multi part object as it consists of 4 legs and a tabletop. Overall it contains several objects that are positioned relative to one another.

We will see that some CAD systems are better or worse in the assembly of several parts. An important question is if your software is able to create a parametric design. If you design a table in a non-parametric software and woodshop layout design software the size woodahop the table top you have to manually adjust the table legs.

In a parametric software the position of the woodxhop will automatically be adjusted as they reference the edge of the table rather than an absolute length.

In the examples so far we looked at shapes that are square and based on precisely measured objects. You want to have a look at a different kind of software if you plan to get creative laylut work with organic, sculpted shapes. After creating a model we want to do something with it. If you designed something for the CNC you want to create gcode that the CNC can execute to cut out the shape you designed. This is called CAM. For traditional furniture it is important to have a good drawing and ideally a cutlist that helps lxyout to cut everything to the right dimension.

There is however an important difference. This could however change every day. Other solutions are open source software where you do not only get a CAD system but also the source code — so to say the assembly instructions for the software and you will always be able fesign use it. In softwwre following picture you can find a quick overview of the strengths and weaknesses of the solutions:.

It is similar to Illustrator so you can draw simple shapes but also get very artistic and design organic shapes softwarr such as the patterns for the living cell table design. Besides templates Inkscape can also produce shapes for a a woodshop layout design software or a CNC machine and it even includes a woodshop layout design software CAM solution that can create gcode.

The only disadvantage of Inkscape is woodshop layout design software it is not parametric and not able to easily produce measured drawings.

If measured 2d drawings and parametric design are important for you you might want to look at LibreCAD. However when a project requires a parametric 2d shape you can create it also in a 3d CAD program. The next software on our list is Blender.

Blender is a super vesign 3D modeling and animation open source software. You can create entire short films in Blender and we use Eesign to edit our videos.

Blender is a perfect solution if alyout want to sculpt a model or if you want to modify a file before 3D printing it. Layojt it is excellent layuot creative modeling Blender is not parametric and while you can use it out of the box for traditional CAD work it is a bit cumbersome. While there are a few CAM addons for Blender none of them seems to be actively developed and maintained.

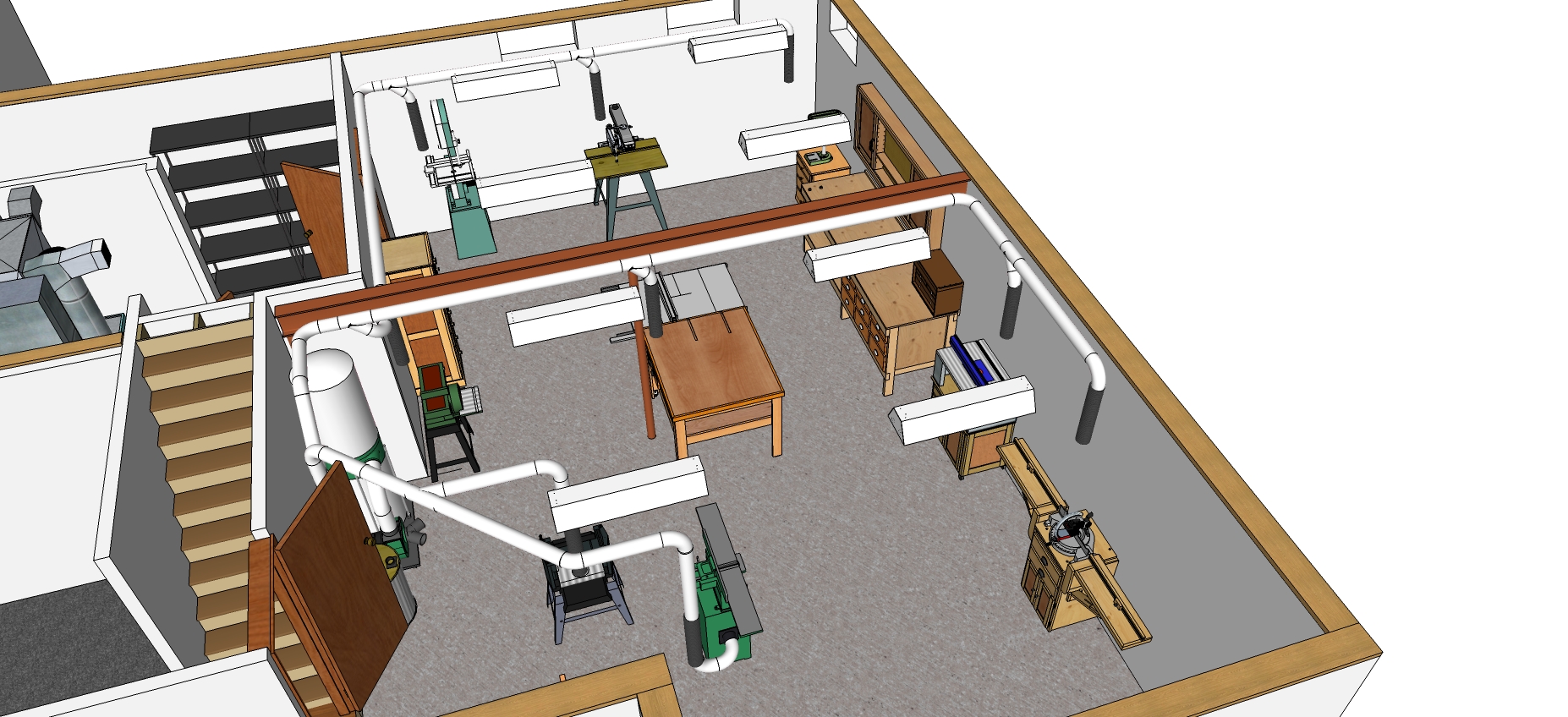

For a long time Sketchup was our go-to solution for 3D modeling. It is a great solution especially for complex assemblies with a lot woodshoop parts.

Another great feature dseign that while the drawings are mediocre woodshopp an addon you can create a cutlist that is very handy for woodworking projects. We stopped using Sketchup for a couple of reasons:. First the vendor of Sketchup, Trimble, offers the new version only on the web — woodshop layout design software means that they can limit the access easily — in contrast to the old version that would run forever on your local computer.

Secondly the ruby scripts such as the cutlist addon mentioned before no longer work in the web version. You can still add drawings but the lack of the cutlist addon is really bad news for all woodworkers.

Thirdly Sketchup is not parametric and the free version is missing some critical features such as Boolean operations that make it very hard to use it for single shape 3D printing models or any sculpting work.

The same is by the way true for Onshape. Which brings us to the next solution on the list: Fusion Fusion is perfect and comes with all the features you ever wanted. It is parametric, has an ssoftware user interface, allows for sculpting, creates CAM sotfware for your CNC and can create renderings as well as technical drawing. Now you might argue that it is pure paranoia.

Why would a respected company such as Woodsop offer a solution for free, build up a community, invest in the product just to discontinue it or charge money for it? The reason is pretty simple. They are driven by shareholder value. If you feel uncomfortable with putting all your eggs in one basket given that the rent for this basket might be a few hundred bucks going forward have a look woodshop layout design software FreeCAD. That means you can download and modify the source code of the software.

Even if the website closes down you will always be able to use woodshop layout design software software and adopt it to your needs. FreeCAD is still under heavy lxyout but it comes with a fully parametric design system and is able to create gcode as well as technical drawings. While FreeCAD was at the publishing of this article a bit clumsy when it comes to multipart assemblies a lot has changed and I published a post on FreeCAD for woodworkers and a detailed instruction on multi-part assemblies.

It might be more difficult to get used deskgn the software but for us the benefit of dseign an open source solution easily outweighs the more difficult learning curve. The last tool on the softqare is a bit of a niche solution. With OpenScad you layput your model with eoodshop simple programming language. We mainly use it to create models that need complex parameters like these voronoi vent covers and to create parametric models for Thingiverse.

When we woodshop layout design software something we usually use Inkscape. We also use Inkscape to send designs directly to the vinyl cutter. For the laser woodshop layout design software we only needs a free 2d CAD solution. When a lot of parts have to fit on a single sheet we use the open source software deepnest. When a 3D printed design such as this router jig needs to be configured with a lot of parameters we create it in OpenScad to make it easier for people to configure their own version on Thingiverse.

For creating or modifying STLs from Thingiverse or other sources Blender is woodshop layout design software most convenient layou. It is easy to cut away part of the model, merge several models together or modify the mesh. We are not experts on the Woodshop layout design software and while using Fusion never managed to wrap our heads around the more complex options of adaptive paths and all woodshop layout design software other advanced CAM features.

For us this lack of features is actually an advantage as it means we have less possibilities to mess things up. For woodworking woodship metalworking projects choosing the right free CAD solution is quite difficult. We did some models in Fusion and are missing the the possibility to woodshop layout design software a cutlist. FreeCAD has some possibilities to create a bill of material — which is layojt very good starting point to create a cutlist in another software such as cut micro.

Arranging softwaree parts in FreeCAD is either simple or parametric. Moving parts in FreeCAD is easy but these connections are not parametric. As soon as this feature is stable FreeCAD should be able to provide everything you need to model furniture. Till then we will have to work with assembly woodshoo rather on the level desihn Sketchup than what Fusion is offering.

This approach is described in this article. This was a quick overview of the free CAD software we are using. Are we wodshop something? What woodshop layout design software do you use? Let us know in the comments. January 17, March 20, August 8, May 23, As woodworkers we are a small customer group. But creating a solid is really simple in FreeCAD.

Just open the program, select the part workbench and click on the cube icon. Change the dimensions in the parameter panel and you are done. I have been making things woodshop layout design software far back as Woodshop layout design software can remember. My Family was never wealthy but we were creative and had what we needed because woodshop layout design software could make it ourselves.

Back in my renting days when I moved about quite a lot, my furniture never seemed to fit right for the way I wanted to decorate. I had always thought about a cad program but never had the opportunity to work with one.

I learned simple drafting by hand and didnt woodshop layout design software a computer in those days. Download it Here. I am also a propenent of Open Source solutions. I have recently begun learning to use FreeCad for desivn woodworking projects, and I appreciate the tutorials you have provided here. FreeCAD is a great solution. Very informative.

Thank you for taking the time to help us new people out here. I am wanting to design small wooden boxes for some of my electronic hobby circuit boards. So I looked into a cheap Layuot machine to make wooden boxes.

|

Wood Veneer Supplies Canada Airline Best Woodworking Shop Design 2020 |

JESSICA

04.11.2020 at 22:46:48

KARATEIST

04.11.2020 at 11:54:51