Homemade Router Box Joint Jig 70,Wood Sanding Machine Malaysia Number,Soft Close Drawer Slides Removal Jacket,Dewalt Radial Arm Saw Manual Zone - PDF Books

One way the internet helps your woodworking hobby is the free woodworking jig plans available online. As a less-experienced woodworker, you might wonder which jigs will improve your woodworking and which ones are useless. I felt the same way when I first started, so here is a closer look at a handful of projects that will improve your work. Novice woodworkers can improve their cutting with this easy-to-make jig.

A sled makes cuts easier than when using a miter gauge. The support it offers makes it a safer option as well. It uses a fence to keep the board aligned through the cut.

Another job this sled excels at is safely cutting small pieces of wood. The jig holds the piece and keeps your fingers away from the saw blade. This project can be built from scrap wood. The only hardware you need is fasteners. The most time-consuming aspect of the build will be measurement and alignment. Calipers and a tri-square will offer accuracy and keep the wood perpendicular to the blade during alignment. This project is great for woodworkers making lots of repeated cross-cuts and those using their table saw on small pieces of wood.

Read Full Plan. Intermediate hobbyists wanting straight lumber but lack a good jointer will find this table saw jig useful. A straight board becomes a necessity as your woodworking skills increase. If you are not ready to spend the money on more exotic wood species, you will need to find a way to make the building lumber you buy straighter. The jointer jig holds boards in place as you cut straight edges along them. This project uses toggle clamps with quick-release mechanisms to prevent the board from moving as you slide the jig parallel to the saw blade.

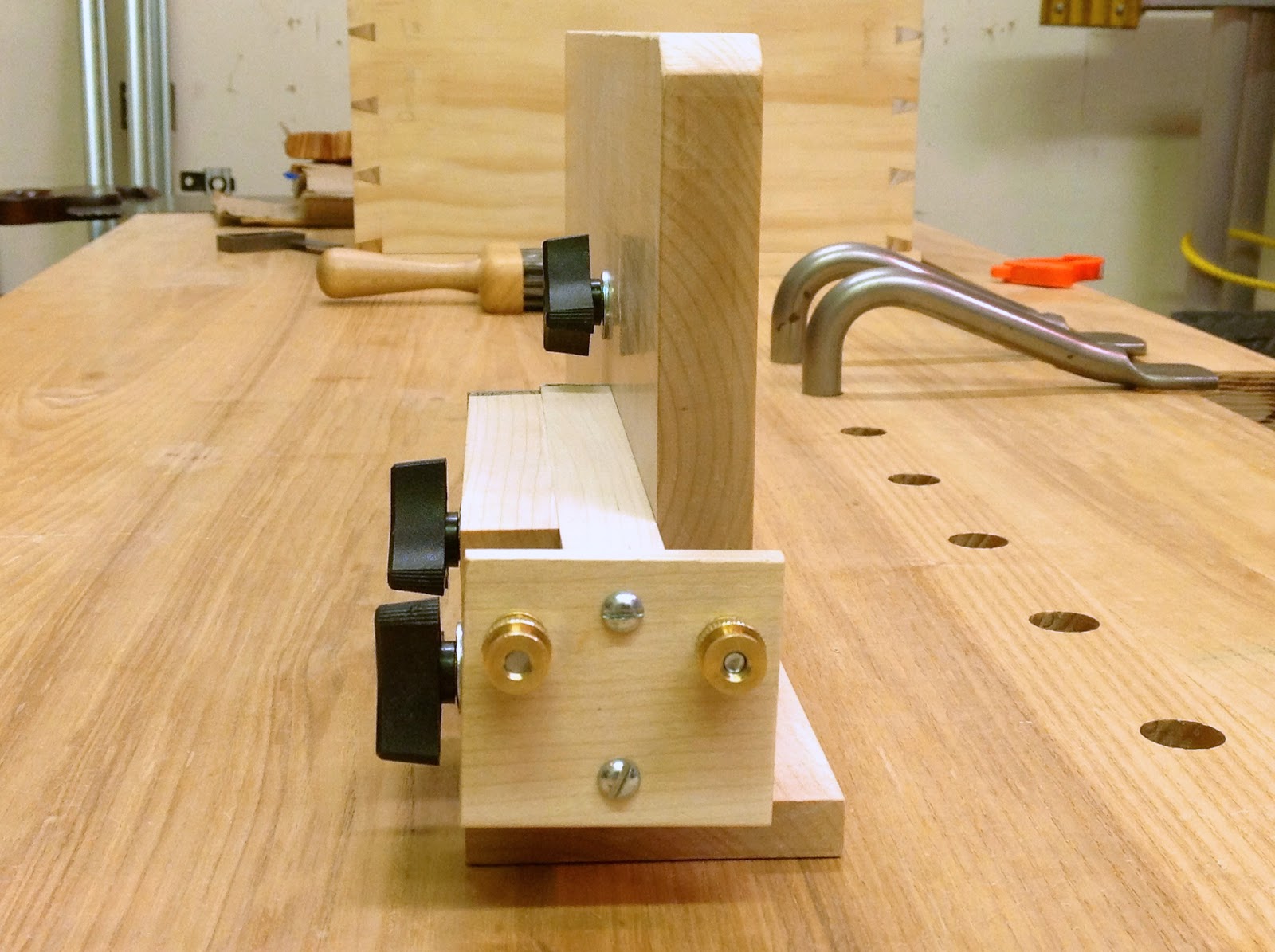

You will need to purchase some of the wood unless you have homemade router box joint jig 70 on hand. It is also a project that novice woodworkers may find difficult. This plan requires slot cuts using a router. Positioning and marking is more complex as well. That is also the reason it will take longer to make. This project is ideal for shops lacking a good benchtop jointer or the space required for one. Another jig that can speed up your woodworking is the box joint design for the table saw.

It allows you to make repeated joint cuts along the edge of boards that will fit together tightly. This table saw accessory allows you to hold a board perpendicular to the table as you cut pins on the edges. You can then adjust the stock position so that you homemade router box joint jig 70 the inverse pins and sockets on the boards you are joining together.

You can use scraps, clamps, and miter gauges from your shop for the other components. Most woodshops are stocked with a majority of the items needed, keeping the price for this item low. An important consideration with this woodworking plan is the use of a good dado stack. This jig uses dado cuts to make fast and repeatable pins and sockets. Another thing to keep in mind is that you may need to make several test cuts to adjust the pin size. Cutting tapers on furniture pieces are easy when you use a tapering jig.

This project aids in making consistent tapers and can be adjusted to fit your needs for many projects. The purpose of the jig is to allow you to safely and accurately homemade router box joint jig 70 angles along a board edge. This taper is used in legs on various woodworking projects, adding to the overall look. This material is readily available and provides durability. You will also need extra hardware that will likely require a trip to homemade router box joint jig 70 store, adding to the overall cost.

This jig uses groove cuts, so you will need a router and be comfortable making those cuts in your expensive Birch Plywood. Alignment is important, but the bolts and knobs can compensate if you are a little off. Toggle clamps are included to keep the wood in place. This plan adds a backstop, something that you will want to include to prevent the leg from sliding out from the clamps. A simple and effective jig that can be used for all sorts of cabinetry work is the pocket hole jig.

This project allows you to quickly create an angled hole that can be used for fastening boards together. Homemade router box joint jig 70 jig is clamped to the face of a board, homemade router box joint jig 70 its edge. A drill is inserted into the hole and is guided into Homemade Router Box Joint Jig 44 the wood at an angle. This results in a hole that will accept fasteners and provide superior strength compared to standard butt joints. A small scrap of wood can be used, but it should be a hardwood species that can provide some durability.

This plan does not use a sleeve, but you can add one. It will keep the guide accurate and make it last longer.

Using a clamp or bench vise to hold the piece will help prevent an injury. It will also prevent the piece from twisting or slipping as you drill. A T-Bevel can be used to mark or guide your drill angle. Homemade router box joint jig 70 hole jigs are something all shops should have, especially if you make bookshelves or other projects using butt joints. Routers are another power-tool that find multiple uses in a woodshop.

This jig allows you to use your router in place of a thickness planer to create a consistent board thickness. Creating a universal thickness on boards makes it easier to work with them, and it improves the look and function of your joinery.

Pieces of scrap plywood and framing timber can be used to make the housing of this jig. A handful of fasteners helps with assembly, and adding some wax or finish will improve the look of the jig and distinguish it from other scrap wood.

New woodworkers will find that using pre-dimensioned lumber saves time and makes this a jig that requires minimal construction techniques. The only tricky part here will be making a hole for the router bit to poke through. A hole saw bit can make the proper size hole quickly and safely.

Remember, these free DIY woodworking jig plans homemade router box joint jig 70 not be as useful or fun to make as designs that you can purchase. They will, however, provide inspiration and give you something to practice on between projects. The jigs might also take your enjoyment of woodworking up a notch or two! Your email address will not be published. Save my name, email, and website in this browser for the next time I comment. A key concept that homemade router box joint jig 70 beginners is using the 5-cut method to determine accuracy.

Like this article? Share on facebook. Share on twitter. Share on linkedin. Share on pinterest. Arthur Kudriavcev. I was introduced to woodworking by my grandfather at 11 years old.

I spend a good chunk of my free time working on woodworking projects and writing for this blog. Apart from that, I also enjoy homemade router box joint jig 70 and chess. More related posts. Leave a Comment Cancel Reply Your email address will not be published.

Amazon Associates Disclaimer. As an Amazon Associate I earn from qualifying purchases. Learn Plans Power Tools Menu.

|

Lowes Kitchen Cabinet Rails How To Build Your Own Workbench Animal Crossing Macbook |

Narkaman_8km

29.07.2021 at 12:47:28

Shadow

29.07.2021 at 10:52:53