Different Types Of Hand Planes Queen,Matt Estlea Marking Knife Uk,Cheap Table Saws Near Me Youtube - Reviews

These planes work where other planes fail, but they take some practice to operate correctly. The finger plane is a small device used for detail work on small objects like instruments and is often used to remove excess glue. These are not adjustable, so you may need to buy more than one to cover every task. Fore planes are larger and can be 14 to 20 inches long. You use these planes to smooth rough board. It quickly removes wood to prepare it for finer tools.

You can also use it to smooth some boards slightly. Jack planes are another larger plane that can be 12 to 17 inches long. Many woodworkers consider the Jack plane the Jack of all trades when it comes to wood planes.

This tool is for removing warps and truing longboards. Jointer planes are the longest planes. This tool can be between 22 and 30 inches long, and because they are so long, you can use them to straighten curved boards. The Kanna is one of the most popular planes in Japan, and many woodworkers consider it one of the best hand planers you can purchase. This tool is a little harder to set up than many others, but its wooden body is more responsive than metal.

The leveling plane is the second most common planer in most workshops and nearly identical to the jointer plane. This plane is slightly wider than others, allowing it to cover more area with each pass.

The wide surface also allows for a straighter cut. Other planes considered leveling planes are the fore plane and the jointer plane. Pictured above is a vintage leveling planer. The molding plane, as the name suggests, is for working on molding and trim. These planes are extremely durable and often made of wood. Molding planes are also essential furniture crafting tools because of the fine detail work you can do with them.

Plough planes have a fence and depth gauge, which allow you to cut grooves into your wood as well as rabbets along the edge. The plough plane is the tool you need for tongue and groove projects. The rabbit plane is specifically for cutting rabbet grooves along the edges of boards. These planes are usually around 10 inches long, and the blade Is slightly wider than the tool to allow for a square cut.

The router plane can get into corners and flatten the bottoms of divets. Modern hand tools are quickly making this plane obsolete, but you can still find them in many workshops. The scrub plane is for removing material quickly. It features a large handle and a sharp blade to prepare large boards for other types of planes. Shoulder planes are like bullnose planes but are larger and can reach up to 8 inches long.

They have a similar use as well, but the larger size helps keep them flat. Smoothing planes are often the last tool used before applying a finish. They are usually 5 to 10 inches long and provide you with a smooth, flat surface.

We hope you have enjoyed our look at the many different hand planes and how they work. If you are looking to purchase one for your workshop, we recommend a jack plane followed by a leveling plane.

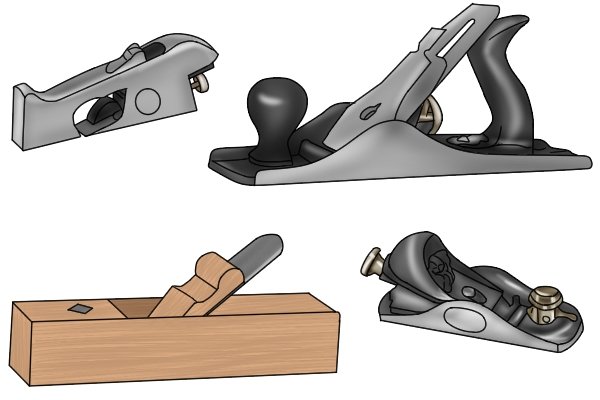

There are some tools that are so different in both form and function that choosing between them is an obvious no-brainer think a saw vs. Ed Malaker Last updated: January 13, Types of Hand Planes These are the 19 different types of hand planes. Bench Plane Image: Pexels Bench planes are the workhorse of hand planes, but unlike most of the other planes on this list, it is not a single tool but is more of a category where several hand planes get lumped.

Block Planes A block plane is the first type of plane that many people get because of its low cost, small size, and versatility. Bull Nose Planes Bull nose planes are small and usually measure between 3 and 4.

Combination Plane Combination planes have an interchangeable cutting blade that you can change to do the tasks of other planes. Compass Plane The compass plane also known as a circular plane has an adjustable curved sole, which allows you to use the plane on a curved surface.

Finger Plane The finger plane is a small device used for detail work on small objects like instruments and is often used to remove excess glue. Fore Planes Fore planes are larger and can be 14 to 20 inches long. Jack Planes Image: Pixabay Jack planes are another larger plane that can be 12 to 17 inches long.

Jointer Planes Jointer planes are the longest planes. Kanna Japanese Planes The Kanna is one of the most popular planes in Japan, and many woodworkers consider it one of the best hand planers you can purchase. Leveling Plane The leveling plane is the second most common planer in most workshops and nearly identical to the jointer plane. Molding Plane Image: Pixabay The molding plane, as the name suggests, is for working on molding and trim.

Plough Planes Plough planes have a fence and depth gauge, which allow you to cut grooves into your wood as well as rabbets along the edge.

Rabbet Planes The rabbit plane is specifically for cutting rabbet grooves along the edges of boards. Router Planes The router plane can get into corners and flatten the bottoms of divets. Shoulder Planes Shoulder planes are like bullnose planes but are larger and can reach up to 8 inches long. Smoothing Planes Smoothing planes are often the last tool used before applying a finish. Parts of a Hand Plane. Blade — The blade handles the cutting.

In the mean time, anyone else have some tips? Depending on where you order the plane from and where you live, it stands a very good chance of cracking, warping, twisting, or suffering from any number of other side-effects of acclimating old, dry wood to a new climate.

I myself have seen this with my own eyes, and there is little that can be done once it has started to happen.

But the reverse can have negative effects as well. Even if the plane has lived in a basement and now you bring it to your unheated garage, bad things can happen. Not to mention many, many of the old wooden planes on EBay have truly seen better days. Most need new irons, are missing wedges, or have already begun to crack, split and twist or are starting to dry-rot. Your best bet is to find a nice old iron plane such as a trusty old Stanley 7 and work with it.

These planes really hold up to the test of time better than the wooden planes that were made a century ago. As well replacement parts are available from a number of sources, and they can be upgraded with better irons and chip-breakers to make them truly exceptional tools.

Very, very good deals can be had on older iron planes. You can get very, very good deals if you keep your eyes open and are willing to spend some time cleaning them up and refurbing them. Just beware of anything too rusted or heavily pitted, as deep pits are something that should be avoided. But, in my experience, planes usually appear to be worse than they really are in the photos, and are often just really dirty.

You will need to learn to flatten soles and tune them up, but there are tons of videos and articles showing this. Keith, I am curious about the ECE jointing plane you show in the video on the 5 top hand planes. I myself am planning on buying an ECE joint plane, as I already have a block plane from them which I love dearly, as well as a toothing plane. I was wondering if you could tell me which model you have?

I know they make a Also, if you could expound a bit on your thoughts and feelings about the plane, I would much appreciate that. There is nothing like a long plane like this one achieve the final flattening of a board. I use mine for bench-top flattening and much more. Kenny makes a good point about timber planes…. Metal bases were often a reflection of a well used plane needing refinishing and the tradesman then fixing a machined steel or brass plate, expertly fixed to the sole.

It added uniform weight to the plane as well. One of the things seeming to be glaring lacking…to me…in this series is reinforced by every example.. I really think, Keith, unless I have missed it…. Choosing cutting direction can be as critical in a small job as a larger one and in fact the whole of the job should be in the mind of the tradesman as he chooses and turns the timber around to see if the grain will aid or disrupt his processes….

How about it Keith…? Like so many things in life, the truth is revealed only over time — by exploring, learning, and experience. So we are on the road anyways towards that goal. Thanks for your enthusiastic contribution here and a great story.

|

Free Woodworking Plans To Build A Baby Cradle Im Rustic Wood Projects That Sell Knit |

XoD_GedeN_909

28.07.2020 at 20:18:29

NERGIZ_132

28.07.2020 at 14:25:17

54

28.07.2020 at 16:14:43

Sex_manyak

28.07.2020 at 20:39:27