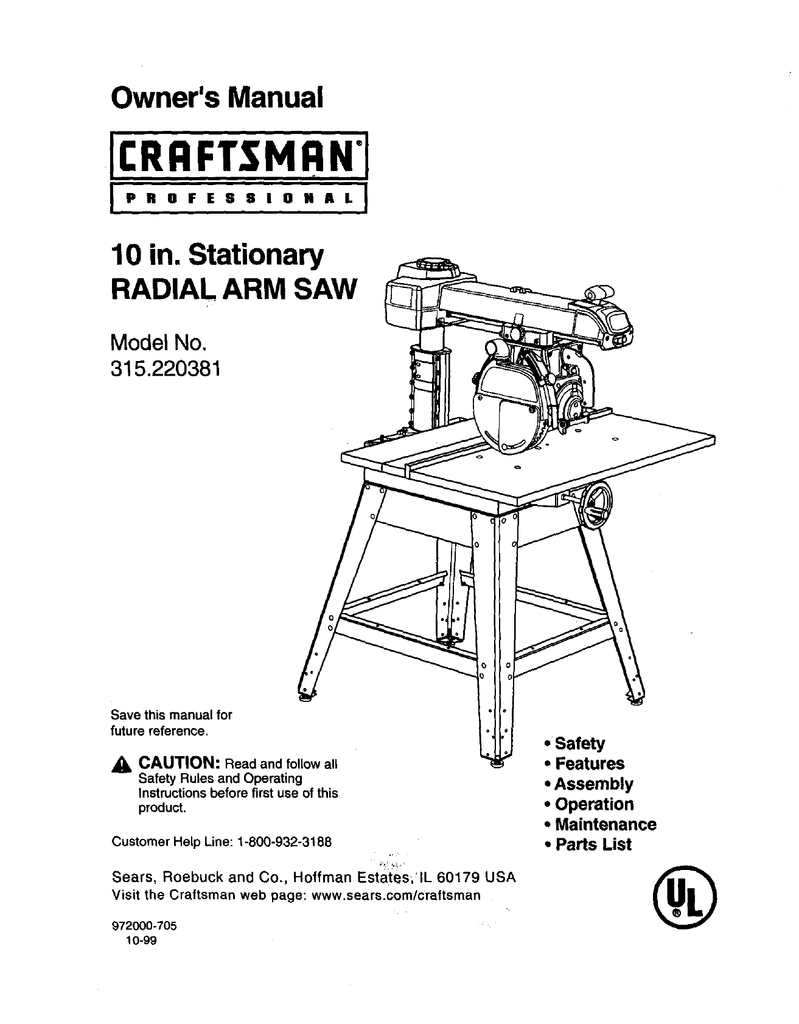

Craftsman Radial Arm Saw Manual Pdf,Woodworking Square Clamp Notification,Woodwork Store Nz - 2021 Feature

Repair Parts Operating Controls Basic Saw Operations Rotate elevation crank clockwise several turns bench, in such a position Page 8 assembly and adjustments 4. Squaring the Crosscut Travel Figures 16 through 23 Figure 19 a. Loosen the carriage lock knob, move the carriage approximate center radial arm, then retighten the lock knob. Install the saw blade, as follows: Place on the motor shaft, in this order: 1 One of Now slowly move the carriage outward along radial arm.

The tooth have marked should just touch the long leg of the square at all points. Page 10 assembly and adjustments Figure 28 7. NOTE: Periodically check, Page 12 electrical connections soon button will snap into running 3. Connections V A. Figure position, the saw may be started and operated normally, by pulling out the saw switch to the "'ON" position.

The wires inside motor terminal must connected as fo! Page 14 operating controls If the radial is already indexed, rotate 6. Power Switch and Key arm-latch handle 18, figure 34 1! This saw cannot be operated without key, arm-latch lever, and move the radial arm off the key cannot Experienced operators of precision equipment, such as your Craftsman Radial-Arm Saw, normally acquire the habit tips anti-kickback pawls should indexing machine in one direction only, whenever Stand a little side center avoid being 6.

Blade should be sharp and correctly set. Hands must be kept wellaway from saw blade. Page 18 safety instructions to operator 1. Be sure to read the following instructions carefully Ripping by applying the feed force to the section before operating the saw. Page 19 Gloves should not be worn while operating the saw. Do not use any blade or other cutting tool marked Loose flowing garments, jewelry rings, wrist watches, an operating speed in excess of the design speed of the etc.

Page 20 Even though finest materials and precision workman- be loosened while adjustment is being made, ship have been incorporated into your Craftsman saw, it is and tightened with medium firmness after reasonable to expect some wear after long periods Gf use. Adjust as described in paragraph "j", following. Bearings Loose on Tracks. Page 22 F,gu,o,8! Page 31 Alignment and Adjustment 6. Use elevation handle to Craftsman Radial Arm Saw Review Pdf raise and lower radial arm a few turns in each direction.

Movement should be smooth but firm. Position hands as in step 3. Feel for movement between column and arm support as you push radial arm side to side. Page 32 Alignment and Adjustment 5. Start with blade over highest point of table as found in step 4. Rotate blade by hand and use elevation handle to slowly lower radial arm until one tooth just touches table. Mark this tooth. Tighten table support bolt that is in line with blade.

Page 34 Alignment and Adjustment Plate Squaring Blade to Table The goal of this adjustment is to make the blade perpendicular to the table so that cuts will be accurate; otherwise cuts will have a slight bevel angle. The Cover Plate bevel scale will also be adjusted. Page 35 Alignment and Adjustment Table Clamp Screw Squaring Blade to Fence The goal in setting the blade perpen- dicular to the fence is to reduce the risk of kickback when ripping.

This adjust- ment will also reduce splintering of the workpiece and burning of the kerr during ripping and crosscutting. Page 36 Alignment and Adjustment 5. Unlock swivel lock, but do not move Swivel Rip Lock swivel index pin. Use Yi6"hex wrench to Lock "Locked" loosen two adjusting screws under ear- riage.

Make adjustment by rotating motor. Page 37 Alignment and Adjustment spreader does not rest flat against fence, go to step 6.

Slide spreader against fence. Tighten spreader nuts. Unlock rip lock and pull blade car- riage forward. Unlock swivel lock, depress swivel index pin, and set blade carriage in out-rip position motor towards fence.

Lock swivel lock. Push blade carriage back until blade is against fence. Page Electrical Connections Electrical Connections This tool is equipped with a two wire Motor Specifications cord and two prong plug which can be used in standard volt A. The double insulated motor used in this No grounding of the tool is necessary. To reduce risk of thrown workpiece: 1. The workpiece is held firmly against the fence, and the blade is pulled through the workpiece to make the cut.

Straight, miter, bevel, and com- pound cuts can be made. Basic Crosscuts Crosscutting Safety Keep one hand on saw handle when turning saw on. Make sure saw slants slightly toward rear. If needed, put shim under front frame. To extend the life of the table top, Refer to the following checklist before make an additional top out of v4" making crosscut kerfs or crosscutting. It plywood or masonite. Clamp or nail to will remind you of things to do to make original table top, section Page 44 Crosscutting Kerfs A kerf or shallow cut is needed in the table and fence to serve as a path for the blade and to ensure that the blade cuts all the way through the workpiece.

A kerr is needed for each different cutting path. Page 45 Crosscutting 7. Plug saw in. Put yellow key in switch. Grasp and hold onto saw handle, then Slowly turn elevation handle dock- wise to lower radial arm until blade touches table, then continue to lower by half turn of elevation handle.

To move to an indexed position, unlock miter lock and pull and hold out miter index pin while moving arm to desired angle.

Page 47 Crosscutting 8. Grasp and hold onto saw handle, Yellow Key then turn saw on. Hold workpiece down and against fence, keeping hand at least 6" away from blade. Hold hand in straight line with saw handle and pull blade through fence Fence and workpiece only far enough to com Check that saw is unplugged, switch is "off' and yellow key is out.

Put fence between front table and spacer board. Tighten table clamps. Bevel Lock 3. Page 49 Crosscutting 9. Grasp and hold onto saw handle, then turn saw on. Bevel Angle Hold workpiece down and against fence, keeping hand at least 6" Page 51 Ripping Workpiece Positioning Always set up so that the widest part of the workpiece is between the blade and fence.

For example, ffyou want to rip 1" off a 10" wide workpiece, set the saw blade 9" from the fence. Page 52 Ripping Ripping Safety The hazards associated with ripping are outfeed zone hazard, kickback, wrong way feed, and thrown chips.

This section explains these hazards and tells how to avoid them or reduce the risk of their happening. Read the ripping safety in- formation and instructions before Page 53 Ripping Kickback Kickback is the uncontrolled propelling of the workpiece back toward the user during ripping. Page 54 Ripping To reduce risk of kickback: 1.

Correctly set pawls and spreader. Spreader keeps workpiece from binding or pinching blade; pawls grab into workpiece to stop or slow kickback if one happens.

Check that spreader is in line with blade. Page 56 Ripping Pawls and Spreader Function The pawls and spreader must be set cor- rectly during tippingt to reduce the risk of kickback, to prevent wrong way feed, and to act as a partial barrier to the haz- ardous ouffeed side of the blade.

The spreader tides in the workpiece kerr to keep it open. Page 57 Ripping Ripping Checklist Refer to the following checklist before making rip kerfs or ripping. It will remind you of things to do to make your cutting safer. Ripping Hints 4. Use the right blade for each job. To extend the life of the table top, 5.

Page 58 Ripping Kerfs A kerr or shallow cut is needed in the table to serve as a path for the blade and to ensure that the blade cuts all the way through the workpiece.

A kerf is needed for each different cutting posi- tion. Page 59 Ripping 6. Unlock rip lock, position blade desired distance from fence, and lock rip lock. In-Rip Position 7. Turn elevation handle clockwise to lower blade until it just clears table. Plug in saw, put yellow key in switch and turn saw on. These steps must be repeated each time a dif- ferent thickness workpiece is ripped.

Check that saw is unplugged, switch is "oft", and yellow key is out. Put solid no kerfs fence in desired position and tighten table clamps. Page 61 Ripping If these conditions are not met, repeat steps 10 and 11 until they are.

Follow ripping set-up procedure. Plug in saw, insert yellow key and turn 3. Stand at infeed side and out of line of workpiece, in case of kickback. Start and finish cut from infeed side. Page Cutting Aides Cutting Aides Cutting aides include fences, push sticks, auxiliary fences, push blocks, featherboards, and straight edges.

Fences Fences are required for all saw opera- tions. Crosscutting requires fences with kerfs slots to match the path of the saw, be- cause the saw blade is pulled through the kerf in the fence to cut the workpiece. Page 64 Cutting Aides Push Sticks Push sticks must be used during ripping to push the workpiece through to com- plete cuts that would bring your hands too close to the blade. Use a push stick when the blade is set 2" or more from the fence.

Page 65 Cutting Aides To make a push block: " Plywood 1. Page 66 Cutting Aides kerf closed, put binding pressure on the blade, and cause kickback. To make a featherboard: 1. Rip to make 5" long cuts about v'4" apart. Use of any other accessory or at- the leading and trailing teeth of the tachment might increase the risk of blade are not exposed from the sides.

Wear These accessories are designed to fit safety goggles this saw. Lower blade guard can get caught Item

|

Euro Style Hinge Installation Work Woodwork Projects 2020 36 Window Frame Router Bit Set Off |

Virus

17.08.2020 at 12:16:31

Sibel

17.08.2020 at 14:39:24

Yalgiz_Oglan

17.08.2020 at 16:42:25

HeDeF

17.08.2020 at 10:21:43

Ninet

17.08.2020 at 17:36:36