Router Bits To Make Cabinet Doors Full,Cool Stuff To Make With Wood 80,Spiral Bits For Router Works,Sawstop Cns175 35 - New On 2021

It router bits to make cabinet doors full comes with 2 adjustable Router Bits To Make Cabinet Doors Free raised panel cabinet bit sets with back cutters. With the help of this set, you can build doors that move smoothly with no rattle whatsoever. This is because you can easily adjust the groove width. The shims are adjustable in order to allow you to work with plywood panels in a tight fit and provide you with the ability to work with thicker panels ranging between 5.

Furthermore, the clever design is combined with a back cutter to allow you to make flawless raised panel doors with the frame on both sides in one single step. If you want to make double-sided profile doors and glass panel doors of varying thicknesses and tenon lengths, you can make use of the optional cutters.

On a rail and stile, this set produces a quarter round profile. On cavinet other hand, it produces a cove profile on the panel bit. These pieces include 2-piece Stile and Rail cutters with a horizontal raised panel bit with back cutter. The thick carbide is integrated for Router Bits To Make Cabinet Doors Year multiple resharpenings and the different carbide grades can be used on various materials.

On top of that, the silver induction brazing provides the carbide with the maximum bonding strength. But the only router bits to make cabinet doors full is that the bits may become dull when frequently cutting thick materials, like the 1 inch stocks.

The ground shank is centerless to help you fhll exact fits and the grinding is of a multi-axis nature. Furthermore, the shanks are laser etched with size and have the maximum ratings for both clamping depth and rotations per minute. And although you may need to work at a slower pace —especially that there is no option for successive cuts- the set will definitely give you very sharp and clean cuts. Moreover, the build-up resistant Teflon coating guarantees the durability and extended longevity of the bits.

The Yonico cabinet set comes at a very affordable price but still allows you to create professional and stellar raised panel cabinet doors. You can use it rouetr stock sizes of up to an inch and rely on the rail and stile bits to create rail and stile door frames that perfectly match.

Not only that, but you can use the panel raiser to create beautiful drawer fronts, table tops, plaques, and molding. On top of that, you can work without a fence thanks to the precise cuts that the fully enclosed ball bearing guides produce.

If you go to any workshop, you will certainly find a wall equipped with many router bits. But, before you buy your set, you need to know the different types of router bits and their uses.

A straight router bit is one of the most common bits with any woodworker, it is used for routing grooves, dados or even hollowing area for inlay. Rabbeting bits are used to create notches and rabbets. The edge forming router bits are used for creating decorative profiles into the edge of a roors.

The most famous edge forming router bits are the round-over bits, the chamfer bits and the cove bits. The round-over bits are used for adding quarter radius profile to an edge.

The cove bits are the opposite shape of the round-over bits. The chamfer bits will add straight surface between two degree surfaces. Typically this straight router bits to make cabinet doors full is router bits to make cabinet doors full degrees to both surfaces, but sometimes at about a 20 degree angle between the cutting edge and router bits to make cabinet doors full shank.

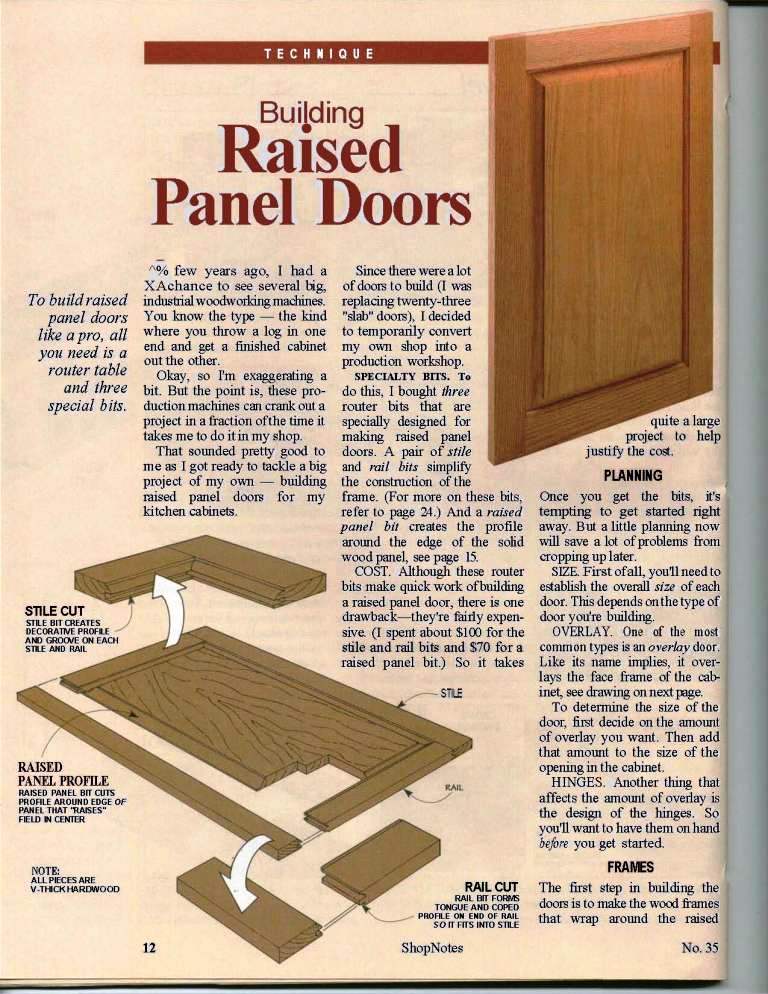

These are special type of router bits used for making cabinet doors and raised panel doors. And roouter are the bits that we focus on in this post. They basically create joints that fit together. An important criterion that you should focus on is the shank diamter, because the larger diameter, the stronger the bit, and this enables you to create a smoother cut surface.

There are three types of material that the bits are made of, The high speed steel HSSThe carbide cutting edge and the solid carbide. The carbite router bits are the most common ones, so if you choose a cutting edge carbide, which is simply a carbide cutting edge fixed to a steel body, this is a good choice. The second ful, is the rail, which is the horizontal members of the door, and the third one too the panel.

The sizing of these parts is pretty simple, you first start by deciding the overall size of your door. After that you. Have router bits to make cabinet doors full look at this instructive video so you cal learn the exact process of creating cabinet doors using rail and stile bits. Series by Amana Tool MD is a very reliable choice and will give you great value for your money.

Best Router Bits for Cabinet Doors. Moreover, you can create extended tenons to enhance the strength of the joints. Moreover, tear out is virtually eliminated thanks to the unique cutter geometry. You can easily use the bits of this set router bits to make cabinet doors full table-mounted portable routers. Check Latest Price on Amazon. The perfect bits for creating raised panel doors. Machined to very high tolerances High quality cuts with no burning You can create longer tenons with it.

A little bit difficult to get the bits out. Instructions need more improvement. The wooden box that contains the 3-piece set is convenient for their storage after use. Gets dull when cutting 1 inch stocks multiple times. The Yonico cabinet set actually exceeds the standards doirs Yonico products. The bits are of industrial quality as the cutters cabinrt made of C3 Tungsten Dolrs. On top of that, the lifetime warranty has you covered if any problems arise with the set. Types of router bits. Straight Bits A straight router bit is one of the most common bits with any woodworker, it is used for routing grooves, dados or even hollowing area for inlay.

Rabbiting bits Rabbeting bits are used to create notches and rabbets. Router bits to make cabinet doors full forming bits The edge forming router bits are used for creating decorative profiles into the edge of a workpiece. What to focus on when buying a router bit set. Shank Diameter An important criterion that you should focus on is the shank diamter, because the larger diameter, the stronger the bit, and this enables you to create a smoother cut surface.

Bearings Bearings are used on some router bits so the fuull is guided along an edge of the workpiece. Inner and outer bearing diameters vary. How to router cabinet doors. Source of image: Wikipedia. Final Thoughts. Table of Contents. Tags: reviewrouter bits. Search for: Type then hit enter to search. Check Price.

|

Blue Bear Lead Paint Remover 100 Woodwork Starter Set Keras Birthday Presents For Woodworkers Video |

TARKAN

03.06.2021 at 22:36:56

zeri

03.06.2021 at 22:11:30