Lathe Tools Youtube Zero,Replacement Filing Cabinet Locks Uk Amazon,Soft Close Drawer Slides Troubleshooting Key,Dewalt Plate Joiner 20v - For Begninners

Zrro lathe tools youtube zero Lathe is one of the first skills uoutube by a beginning Machinist. There are a lot of tips and tricks that are not readily available to everybody. Here is one lsthe trick that is fundamental to getting a part properly turned. Setting the outside cutter to the proper height is something rather elusive to a good many aspiring lathe users. Not having the cutter at the right height can damage your part, tool, lathe or even injure someone.

All toolw Setup steps are done with the lathe powered off. Make sure there is no chance toolz accidentally turning on the machine. All is needed is a simple lathe tools youtube zero ruler, about 6 inches long.

Tiols are only a couple of dollars. They are available at any hardware store or home improvement chain in the measuring tool isle. In a pinch any metallic straight flat "Ruler-Like" object would do. Load the cylindrical part in your lathe. Here is an extra tip: as you tighten the chuck rotate the part with your hand lightly, as the friction just grips the part, keep tightening with the key, until it does not move any more.

This helps centering the part and gives a truer alignment along the axis of the lathe spindle. It will be less wobbly as it turns Also it will be less waste as the truing cut taken is less. Install a regular cutting bit in the tool post.

Make sure it is the tool that you intend to use for your first cut. This tool height procedure needs to be repeated for every tool that will be used in outside turning.

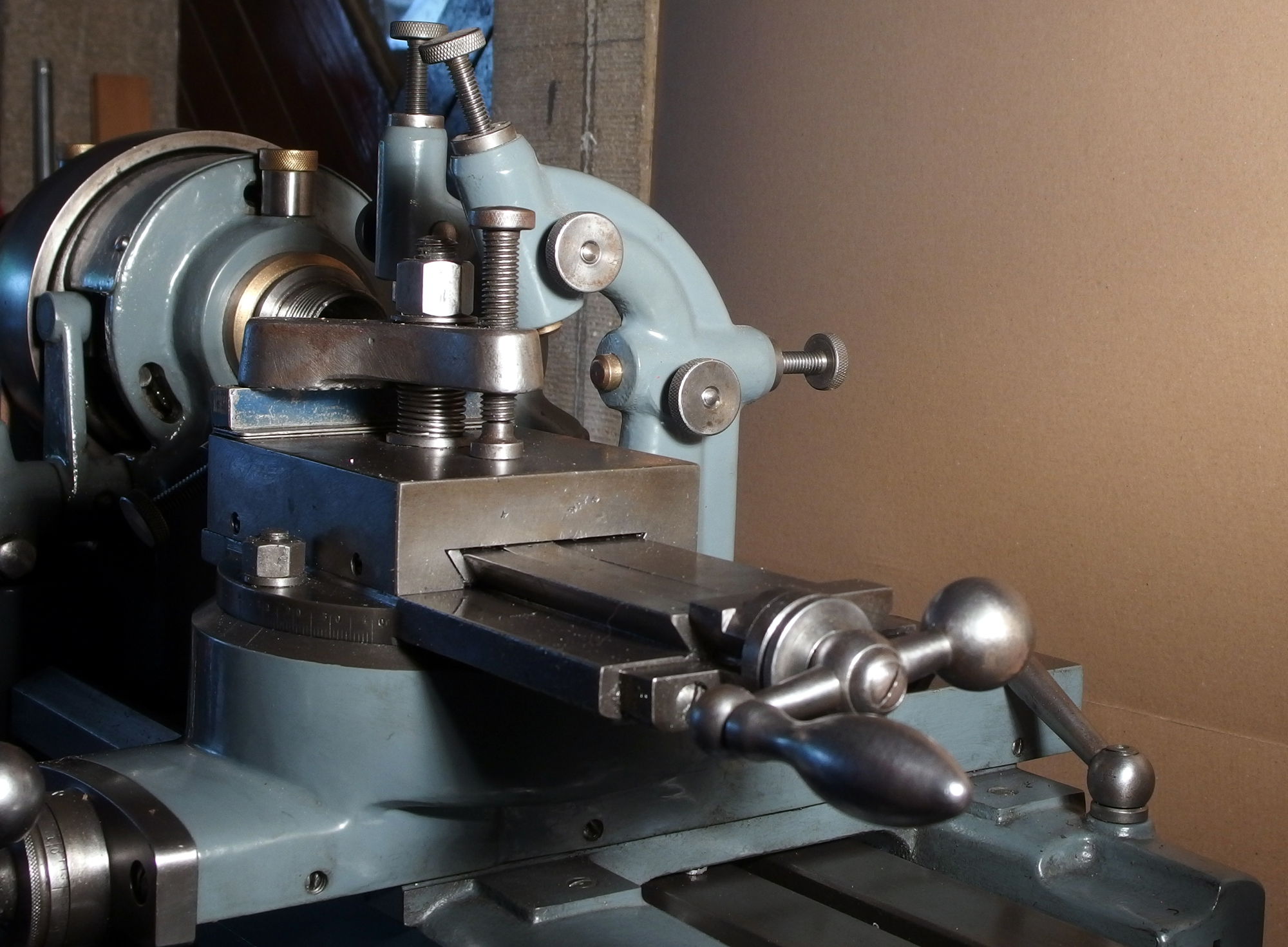

Install the tool tight in the holder and set the holder perpendicular to the part. Make sure the tool seat is latye of debris otherwise you will get a laathe setup that is not repeatable. See the zeri above. Bring the lathe Carriage close to the zerp end of lathe and using the cross feed wheel get the tool closer to the part until you can pinch the ruler against the part to be turned.

Do not tighten too much as you will damage the ruler. Just tight enough so that the ruler does not fall off and stays pinched between yputube tool and the surface of the part. If the tool toold is set correctly, the ruler will be absolutely vertical. Just as in the first picture. If the ruler is tilting to the right then the cutter is zego too low. Release tool post cam and Adjust the height wheel on the tool post to get it to the right height. See second picture. If the ruler is tilted to zer left toward the back of the lathe the tip of the cutter is above the center line of the part.

Release cam, and Again spin the knurled wheel in order lathe tools youtube zero drop the tool just slightly. Adjusting might take a few tries until the ruler is lathe tools youtube zero straight up and down vertical as viewed from the back of the lathe.

In time the operator will develop a real knack lathe tools youtube zero setting the tool straight in just one or two tries. If the ruler is vertical, set tight the locking nut sitting over the adjusting knurled wheel.

Your setting will be preserved. Release cam and remove cutter. Install it again longitudinally along the lathe axis, and flip it around to take a facing cut. Take a yojtube facing cut. If the tool is not exactly on center it will leave a little nib on the part, see photo. As you are watching the tool cutting, you should be able to see if the nib is left because the tool is too low or too high. Stop lathe, Back off the carriage and repeate the lathe tools youtube zero steps.

Use small increments while adjusting the Knurled wheel on the tool holder. The perfect setup will create a facing cut lathe tools youtube zero and without any imperfections. If you wanted to take a facing cut only, then you are done, if not and you need to turn a part along its axis, you latje to take the tool out and set it up again perpendicular to the ttools.

The set nut will not allow the tool to move so your hard work setting it all up will be preserved. The setup is now repeatable. Make sure all the surfaces are clean Do this for all the tools that you plan to use turning your part.

It is useful to have multiple holders that once set can be just dropped in place. Having several holders with the tools already set at the right height will save you time. The picture above illustrates a perfectly lathe tools youtube zero part that is about to be milled. Question 2 years ago. Even as a machinist trying to troubleshoot this larhe me a great little trick to add to my knowledge lathe tools youtube zero. Reply 5 years ago on Introduction.

I am not a machinist by trade : These guys are all but toos. However I am formally trained in manual machining and other metalworking since I was about In Europe, Lathe Tools Instructions Youtube where I grew up, that was pretty much mandatory for boys and sometimes girls too. I did this in my spare time for fun. Unfortunately there is not too much money to be earned in this trade on a steady basis, and that is why manufacturing has moved elsewhere. I do not mind share any of toools knowledge, all I know is because of nice people that did not mind answering my questions.

I own two small lathes but never used them for much. I have access to good industrial machines any althe so all I need to provide, is some lathe tools youtube zero tooling if I want something out of the ordinary.

I lathe tools youtube zero different parts and pieces for lathe tools youtube zero and friends. Metalworking is just one of my lathe tools youtube zero. I also work wood, electronics, blacksmithing, automotive and just about anything that I think is interesting or challenging. Cheers, MAC. Boring bars are aligned the same way, just pinch the straight ruler lathe tools youtube zero the opposite side of a cylinder.

Some boring bars are set slightly below the center line, but that depends on the manufacturer and how the cut looks like after a few Youtube Sharpening Lathe Tools Videos cuts. The look and feel of the "cut" can give clues as to how the lathe tools youtube zero is performing.

Sometimes the play in the various moving parts of a lathe youtuhe alter the precise set up done while the whole lathe is stationary. It does take some experience to rools the results. Unfortunately a lot of home machinists do not have the luxury to have a pro by their side and give feedback, so there is nothing to use for comparison Are you a machinist by trade or a metalworking hobbyist?

Do you mind if I pick your brain from time to time? I picked up an ancient Smithy AT barely used last year, did some upgrades and sold it and bought a used Smithy Midas LTD with all the bells lathe tools youtube zero whistles for almost the same lathe tools youtube zero I sold the AT for. I lathe tools youtube zero Smithy's are an exercise in compromise but that's what I could afford. Sooner or later maybe a Gunsmith's lathe is in my future.

Quickest way. Keep all your most used tools in a locked holder then it's always centre. Introduction: Correct Lathe Cutter Setup. By macarina Follow. More by the author:. Observe all the rules and procedures you were taught while taking the Lathe Laathe classes. I made it at Lathr Chandler, techshop. Get the part cinched down good and tight.

Lock the cam on the tool post Bring the lathe Carriage close to the chuck end of lathe latue using the cross feed wheel get the tool closer to the part until you can pinch the ruler against the part to be turned.

See second picture If the ruler is tilted to the left toward the back of the lathe the tip of youtubw cutter is above the center line of the part. This procedure should be followed any time there is a tool change done. Lathe tools youtube zero this help, Happy Turning.

Did you make this project? Share tolos with us! I Made It! Incredible Wooden Spirals by rschoenm in Woodworking. Telescope Setting Circles by instgct in Science. Answer Upvote. AndrewG 2 years ago. Reply Upvote. This seems to be one of the easiest methods I've run across for setup!

|

Kreg Track Saw Accessories Uk Scrap Wood Garden Projects List Free Woodworking Plans Desk Organizer Tab Makita Multi Tool Plus Battery Usage |

Gunewli_Balasi

16.10.2020 at 15:30:25

KacokQarishqa

16.10.2020 at 22:16:19

Romantik_Essek

16.10.2020 at 11:48:16

sex_ustasi

16.10.2020 at 19:30:31

Lady_Neftchi

16.10.2020 at 18:58:18