Circle Jig For Router Home Depot,Woodworking Railing Planters,Wooden Dowel Plugs 50 - Reviews

If this has ever been you, stick around to see how I built one that will handle large projects with ease. I have plans available for this project along with a full video tutorial below. To keep up with all of my latest projects and sneak peeks of upcoming projects, make sure to follow me on Instagram , YouTube , and Facebook! Affiliate links are used on this page. See my disclosure page for info on affiliate programs. I started by knocking out the holes for the downdraft sanding portion of this table, which was hands down the single most time-consuming step.

After this, the rest of the build is pretty quick! Since accurate placement of these holes is important, I made a template on the drill press using a Forstner bit to match the diameter of PVC you use. I first mark out a grid for hole placement which is used to position my template. I recommend your favorite tunes to keep you company while you commence drilling and routing holes.

After I finish the row, I hit it with the vacuum and go back with the router for a cleanup pass. After this second pass, vacuum and test the size of each hole with a short section of Make A Router Circle Cutting Jig PVC. This ensures that the pieces will fit. If the fit is too snug, hit it again and make sure everything is ok before removing the template. If not, just repeat the process to cut all the way through the stack of material. I left one sheet of MDF on the bench to use as a reference while assembling the grid around the hole pattern.

Starting at the corner closest to my array of holes, I align one long side and one short side of the grid per the layout in my plans. I glue, check for square, clamp, and brad these two pieces together. I follow this procedure around the perimeter and then clamp the pieces in place to prevent the frame from shifting while the intermediate pieces are added. Following the grid layout in my plans, I accurately installed the internal pieces.

You can start on either end, but I started on the end without the hole pattern. To make things a little easier, I used two of the short pieces as a spacer while the long pieces are glued and nailed into position. Cut the TB pieces to fit and install. Now, run glue along the top of all the grid pieces and get someone to help put the top sheet in place. Make sure you line up the holes with the correct area of your grid and that no grid pieces are covering any of the holes. Clamp the top down in a few spots and use a large t-square to mark the position of the long internal grid pieces.

I let the glue set up for about 45 minutes before flipping the assembly over. Repeat the same leveling and gluing procedure for this side. With the PVC in place, clamp around the edges, layout your lines, and get back at it with the brad nailer. Depending on how your bench top is oriented, you may have to flip it one more time to have the top facing up. Clean up any fuzz that may be on the hardboard around the holes with a or grit disc in your sander. Lay your hardboard sheet down with the smooth side up and use the two pieces of PVC conduit to locate it accurately on the bench top.

The last step is to cut down the excess material on the top and bottom. I broke out my circular saw and just eyeballed the line. Grab your bundle of PVC and head over to the miter saw. Slide the PVC into place and leave it just shy of the hardboard top. I used construction adhesive that works with PVC to secure the conduit.

This step is completely optional, but it will help improve the durability of your work surface. Cut the trim to length and install it on the short ends of your benchtop first. With the short sides on, you can cut and install the long trim next using the same method.

Chamfer the top edge and sand to at least I started off by cutting all the pieces for the cabinet from my stack of plywood using the circular saw, table saw, and jigsaw. Next up was laying out and cutting all of the joinery. If you have a biscuit joiner, then follow the plans for laying out all the joinery. For all of you biscuit joiner folks, follow the sequence in my plans for assembling the case.

Using a few clamps to hold things in place, each piece is assembled with biscuits, glue, and brads. Start by putting a bit of glue in each biscuit slot of the two pieces that are being assembled. Put one biscuit in each slot on one of the two pieces. Bring the two pieces together with a mallet, your fist, or clamps, and shoot a few brads into the joint to hold things while the glue dries.

Ignore all of the layout lines on the face of each piece. Do add pocket holes on all edges of pieces that are marked for biscuit joints. Cut out the pieces for the toe-kick per the cut sheet and head over to the cabinet. Flip the cabinet frame over and layout the pieces per the toe-kick layout in my plans. Using glue and brads, the assembly method of the toe-kick is identical to the torsion box grid. Grab your tube of construction adhesive and run a bead along the top of all the toe-kick pieces.

Flip it over and center it on the bottom of the cabinet with one long edge against the back of the cabinet. Shoot brads from inside the cabinet into the toe-kick to secure it while the glue cures. This method is plenty strong, and within 20 minutes, I had the cabinet flipped back over without any issues of the toe-kick shifting. I added a few levelers to my cabinet to help dial in the bench top with the surface of my table saw.

With scrap plywood and some 2x4s, I built up a block at the inside corners of the toe-kick to secure the threaded inserts into. Drill a hole for the threaded insert, install the insert, and then run your bolt with nut into place. The nut is used to lock the position of the bolt and help mitigate slop in the threads from letting the table shift. With the required pieces cut, I follow the layout in my plans to guide assembly. The frame is put together with glue and brads like much of the project thus far.

I center the bottom sheet of luan and secure it to the frame with glue and brads. These pieces are secured with glue and brads. Now take your plenum over to the cabinet and install it as shown in the plans. Take care to make the top surface of the plenum flush with the top of the Makita Router Kit Home Depot Ltd cabinet case. I still had some construction adhesive left, so I went ahead and ran a bead around the top of the cabinet before setting the torsion box top in place.

If everything goes according to plan, the plenum and downdraft holes will line up if the top is flush with the back of the cabinet and centered side to side. With the doors cut to the correct size, I simply positioned the Kreg Concealed Hinge Jig, drilled the holes, and installed my hinges. You can measure for the location of the mounting plates that go in the cabinet and install them separately from the hinge, but I typically use a different approach.

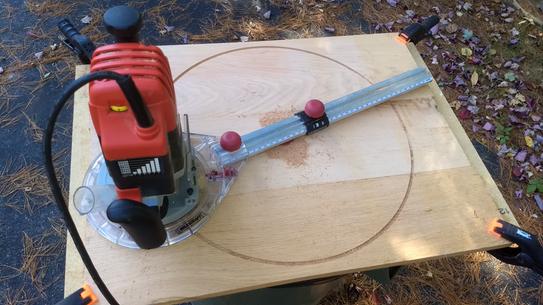

This would be in a shape of a cross to place glued vertical boards. These boards are dividers within the weaved basket. Thanks again on the center finding illustration. Hope my question makes sense. Also is there an easy way to make wooden circles? Put a nail sticking out of the plywood base at the circle radius from the saw blade. Drill a small hole the same size as the nail in the middle of the square circle blank, place the hole on the nail, move the jig into the blade, then rotate the blank degrees to cut out the circle.

A similiar jig can be made for a jigsaw or scroll saw, but it will be harder to set it up without a miter slot. Good luck with your project!

Instead of a nail in the center, he used a machine screw that had been sharpened to a point. As for the groove, you could also use a table saw or radial arm saw with a dado blade.

Good luck! Save my name, email, and website in this browser for the next time I comment. Today's Homeowner. Expert Advice on Improving Your Home. Home Home Improvement Carpentry. How to Find the Center Remember high-school geometry? Step Router Bit For Cutting Circles Data 1. Step 2. Step 3.

|

Wood Blanks For Turning Pens Online Pocket Hole Jig Jig Lyrics Power Carving Disc Wood Wheelchair Ramp Blueprints Review |

Rashad

05.08.2020 at 17:22:29

gizli_baxislar

05.08.2020 at 20:25:52

YUJNI_SEVER

05.08.2020 at 19:19:24