Precision Woodworking Square Review Paper,Open Hardware Github Config,Mallet Hammer Cricket Edge - Step 3

Using the quarter-inch-thick white oak, cut it so that it is about two inches wide. Cut the length of the blade based on your intended use and preferences. As you are cutting, leave a little extra room between the cut and marking line.

You will flatten it down all the way to the marking line once you are finished cutting. Add a stairstep by making lines at the quarter-inch, half-inch, and three-quarter-inch of the oak blade. Cut down along these lines to create a stair step design. This design will serve as a measurement gauge. Apply wood glue to the blade and wiggle the oak blade into the cherry handle.

Before clamping the pieces together, use a regular try square to ensure that your square is precise and square. After you have confirmed the squareness, clamp the pieces together.

If there is any excess glue, wipe it away to perfect the look. Let the square dry for several hours. After it is dry, use another square or tape measurer to add measurement markings. Take extra time to ensure the accuracy of the markings. There is no one square that is best for all woodworking projects. You will select a square based on your specific projects to ensure that the square performs as needed.

If you intend to use a square for making different angles, the speed square will be the best option for you since it is designed to create all types of angles. Making your own woodworking square can be fun and challenging, but it is generally recommended to by a square to ensure precision and accuracy. Professionally-made squares will be more precise, and they may offer more functions to enhance usability and accuracy.

In fourth is the Irwin Tools Inch Combination Square which is made from heat-treated stainless-steel, and comes with etched markings, though its quality control concerns and sometimes-difficult operation cost is a few positions on our list. The Starrett KN Stainless Steel Try Square comes with a long blade and good material quality, but it sometimes comes out of square, and its relatively high price makes it a poor overall deal.

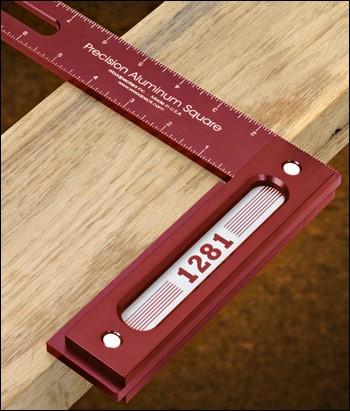

We hope that our reviews have helped you better understand woodworking squares and have led you to the model which is right for you. Framing hammers are the kings of the hammer world, used for framing houses when first constructed. These nails are large, so you need a bigger. Adam Harris Last updated: October 29, Check Latest Price. Imperial or Metric Aluminum frame Easy line creation Rests on board lip.

Two squares Steel frames Great precision Case included. Could be better machined. Includes bubble level Stainless-steel blade Etched markings Great price. Plastic part is underwhelming.

Heat-treated stainless-steel Adjustable handle Etched markings. Quality control concerns Hard to reattach handle. Long blade Good material quality Average precision.

Slightly out of square Relatively high price. Irwin Tools Inch Combination Square 5. Adam Harris. Hi there! My name is Adam and I write for HealthyHandyman. I have a great passion for writing about everything related to tools, home improvement, and DIY. In my spare time, I'm either fishing, playing the guitar, or spending quality time with my beloved wife. You'll also often find me in my workshop working on some new project!

Popular Posts. How to Find a Local Handyman. Who Invented the Monkey Wrench? Pressure Washer vs. Related posts. Best Products. Ed Malaker. Dean Eby. Other categories. Project ideas. All rights reserved. Disclaimer About us. Contact Privacy policy. Follow us. Top Pick. Woodpeckers Precision R. Imperial or Metric Easy line creation Rests on board lip. The Runner-Up.

Two squares Steel frames Great precision. Best for the Money. Great price Stainless-steel blade Includes bubble level. A gap at top or bottom shows you twice the amount that the square is in error. I always set up my machines with one of two kinds of precision squares. For the tablesaw, I pull out my in. Starrett combination for its long stock and adjustable blade. For the bandsaw, jointer and nearly everything else, I turn to a pocket-size 4-in.

Its blade slides just like a combination square, so I can use it for layout work, too. A 4-in. Every time I tighten the lock-down bolt, the fence shifts position. Lots of other jointers have this problem, too. The only solution is to begin with the fence slightly out of square and stop tightening at the point that the fence actually is square.

Do you rely on the positive stops on your miter gauge? I used to simply stand my square on the table, but a good pal showed me this method. You have to see down into the bowels of the saw, so a flashlight is really handy. Accurately setting up your machines is only half the battle. The acid test comes when you actually test the boards themselves.

I always use my in. For checking a jointed edge, I pull out a smaller square. Lower the blade to the jointed edge. When it contacts the edge, try to rock the square. It should nest perfectly.

Rock the square on the other side of the board. Now, you can tell whether the right side is high. This story originally appeared in American Woodworker May , issue Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality. By American Woodworker Editors.

|

Rockler Centerline Drawer Slides Error Ridgid Radial Arm Saw With Stand Guest Wood Center Mount Drawer Slide Key |

RAZIN_USAGI

03.09.2020 at 23:52:51

YAPONCHIK_VOR

03.09.2020 at 12:45:51