Open Hardware Pick And Place Key,Fine Wood Carvings Waxahachie Texas State,Woodwork Night Classes 50 - Plans Download

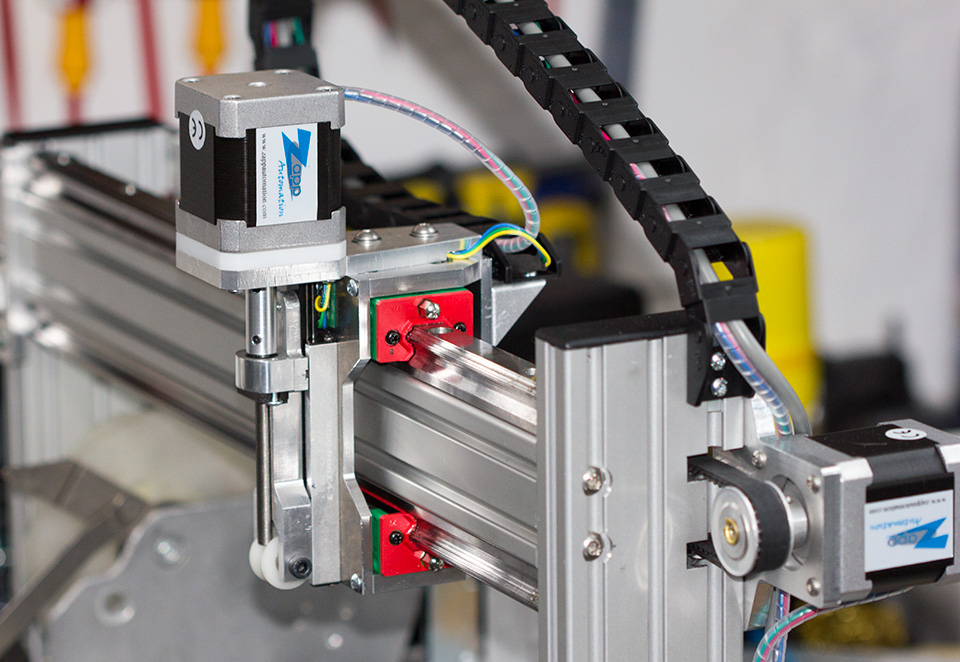

Citrus CNC tries to address the cost issue with the SimplePnP open source hardware pick-and-place machine that brings the price down to several hundred dollars. SimplePnP key features and specifications:. As the comparison table above, SimplePnP is not the first open source hardware pick-and-placer around, but offer a much cheaper option compared to LitePlacer. The latter does provide a fairly larger work area however.

Jean-Luc started CNX Software in as a part-time endeavor, before quitting his job as a software engineering manager, and starting to write daily news, and reviews full time later in Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website.

These cookies do not store any personal information. Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It was named Mr. When the valve switches to blow mode, the pressure built up in Mr. Sneeze is used to eject the component from the end of the vacuum tweezers. Without doing calculations I resorted to trial-and-error to establish the reservoir size.

If I was building it again I would just use a smaller container. To control the pressure a regulator is used. Even without the regulator anything bad is unlikely to happen the low cost pump will probably leak and the tubing will pop off if there was any extreme pressure build-up but the regulator is inexpensive to add and provides more control over the behaviour when releasing components from the vacuum.

To operate the valve a foot-switch is used. The reason for this is to increase user efficiency; the conveniently-placed LCD display can be used to indicate the component reference and value for the next part that needs to be picked and placed. Once the part has been placed the user can perform a double-press on the foot-switch to advance the display onto the next component that needs to be placed. The idea could be extended even further to automatically highlight where on the board the next component needs to go perhaps Open Hardware Android Phone Key display it on the computer screen.

If the user makes an error the display could be reverted with a triple-press. There are also buttons on the unit that could be optionally used. The vacuum tweezer end of the design was based around easy-to-obtain syringe dispensing tips nozzles. They come in different colour-coded diameters.

The brown one is perfect for sized parts and larger, but the yellow one is great with and parts and even some ICs. The yellow one will therefore be used the most. To make the vacuum pen a plastic bottle intended for eyeliner was used.

I liked it because it has two flattened sides so that if the handle is placed down and then subsequently picked up, it can very quickly be held in the same exact orientation as before, which is critical when the dispensing tip has been bent at an angle in the desire for good ergonomics.

The brush end was removed with pliers and the stem was found to be hollow so all that was required was to chop the end off for the tubing to pass through. Throughout the design of this project thin 4mm tubing was used 2. Another benefit of the plastic bottle method is that there can be lots of room so it would be quite easy in a future upgrade to build a version with a white LED inside it and run thin wires inside the tubing to supply illumination.

It was considered a nice-to-have feature but not essential to this first vacuum pen prototype. An alternative approach to creating a vacuum pen could be to 3D-print it based on any custom design. As mentioned the nozzle part of the design was based around syringe dispensing tips with a standard fitting known as a Luer fit. Thank you to our software sponsors:. Thanks to ej-technologies for providing a complimentary license of install4j.

YourKit supports open source projects with its full-featured Java Profiler. NET Profiler , innovative and intelligent tools for profiling Java and.

|

Wooden Boat Magazine Australia Kitchen Cabinet Drawer Slides And Hardware Pocket Hole Jig Nairobi 65 |

svetlana

16.09.2020 at 18:14:44

Gozel

16.09.2020 at 16:21:23

DYAVOL_no_DOBRIY

16.09.2020 at 11:19:51

Kolobok

16.09.2020 at 14:52:38