Lathe Tools Grind Zoom,Jet Planes Cannot Move In Air Free Space Why Item,Wood Bowl Blanks Uk Sale,Molding Bit 8bit - 2021 Feature

As a final step, you may wish to smooth the cutting tip on a fine diamond hone or oilstone. I've found that the tip tends to get smoothed pretty quickly after a few cuts, so I usually skip this step, but it does make a difference if you need a fine finish.

So now you know how to grind the most basic of cutting tools. There are many other types of tools that you can grind including shaping tools, cutoff tools and boring tools. Here's some additional info posted by Brian Pitt:.

You usually want to set the tool on center to about. One of the most important facts often overlooked by beginners is that the cutting face of the grindstone wheel quickly becomes dulled and clogged with metal particles. To maintain an aggressive cutting face it is essential to refurbish the wheel face frequently with a dressing tool. I use a dressing tool with a single industrial diamond point for this purpose. I use this tool to refresh the grinder wheel after about every 10 minutes of grinding time.

It makes a big difference. Here's some great information on various types of tool rake, posted by Dub Thornton:. No, rake angles and front relief are NOT the same. Front relief is the angle ground into the front of your tool which allows ONLY the front cutting edge to contact the workpiece.

If the tool contacts the workpiece below the cutting edge, you will get a "rubbing" action, and the tool cannot bite into the workpiece.

Side relief or clearance is the angle ground into the side of the tool which allows only the side cutting edge of the tool to contact the workpiece. There are two rake angles, both on the top of the tool. Back Rake is the angle from the tip of the cutting tool toward the back of the tool.

It may be either positive, neutral, or negative. If it slopes down from the tip of the tool toward the back of tool, it is positive rake, an upward slope would be negative rake, neutral is self explanatory. Rake angles, particularly back rake, may be built into the tool holders. The old lantern type holders I grew up on usually had a positive back rake angle built in. This was a help when grinding your tools, as you did not have to grind any back rake into the tool itself.

When grinding threads tho, a neutral back rake angle is desirable, thus one had to grind a negative rake angle point of tool pointed downward to compensate for the positive back rake angle built into the tool holders. Map It. Phone :. Toll Free Phone :. View Website. Send Email. View in Buyers Guide. June 18, Cutting Tool Engineering.

One fine and one coarse belt. That will give me a good excuse to upgrade to a better bench grinder too. Many thanks Mike,this is excellent. I only found this site a week ago and I now see how to navigate around. As a knife Sharpening Lathe Tools Without Jig Zoom maker I have good belt grinders with belt width of both 30 and 50 mm. Thanks for the compliment, Wally. I do hope it helps you. If you go for it, let us know how it works out for you.

I have only used AO on my tool grinding belt sander but use Zirconia on my 4 X 24 sander all the time. AO is cheap, readily available and works really well on my machine. I have not used ceramic belts so cannot attest to how well they work — sorry. If I were to buy a belt sander today I would look for something that uses belts of common size.

A 2 X 72 or even a 2 X 48 would be about right. The ready availability and cost of the belts is a big consideration, mainly because we cannot stockpile them for when we need them. The splice has a definite shelf life so they have to be fairly fresh. It might work for your needs, however, so go with what you think best, Fred. Sounds like a great solution, Brian. In these holders the tool is angled up at a 7 degrees.

It seems to me that this going to affect the angle that is set on the belt grinder tool rest. If this is so, how does one compensate and how many sides does this affect? Using the lantern tool post does create a problem because of the built-in 7 degree angle the tool is presented at. This negates 7 degrees of relief so it would seem to me that you would need to add that 7 degrees to whatever angle you are grinding. For example, if you wanted 15 degrees of side or end relief you would have to set the grinder table to 22 degrees.

For the rake angles, I would grind them normally and see how it goes. My main concern would be getting the right relief angles ground so you get the clearance you need. You will need to take shallower cuts as the edge is not well supported but it should work. I am also a new guy as you.

And i wondered whether how the operation speed of the belt sander. After reading your article, it helps me understand several problems.

Just came in trying to use my belt grinder to grind HSS, also first time grinding. I have a slow motor on it, mostly used it to sharpen chisels and other tools. Dennis, have you tried ceramic belts on your sander? I have and I found them to be far better than Aluminum Oxide belts. It also sounds like your platen might be part of your problem. A platen should have square edges; not sharp, but square. I prefer a glass platen liner and find that my belts do not wear excessively on the edges.

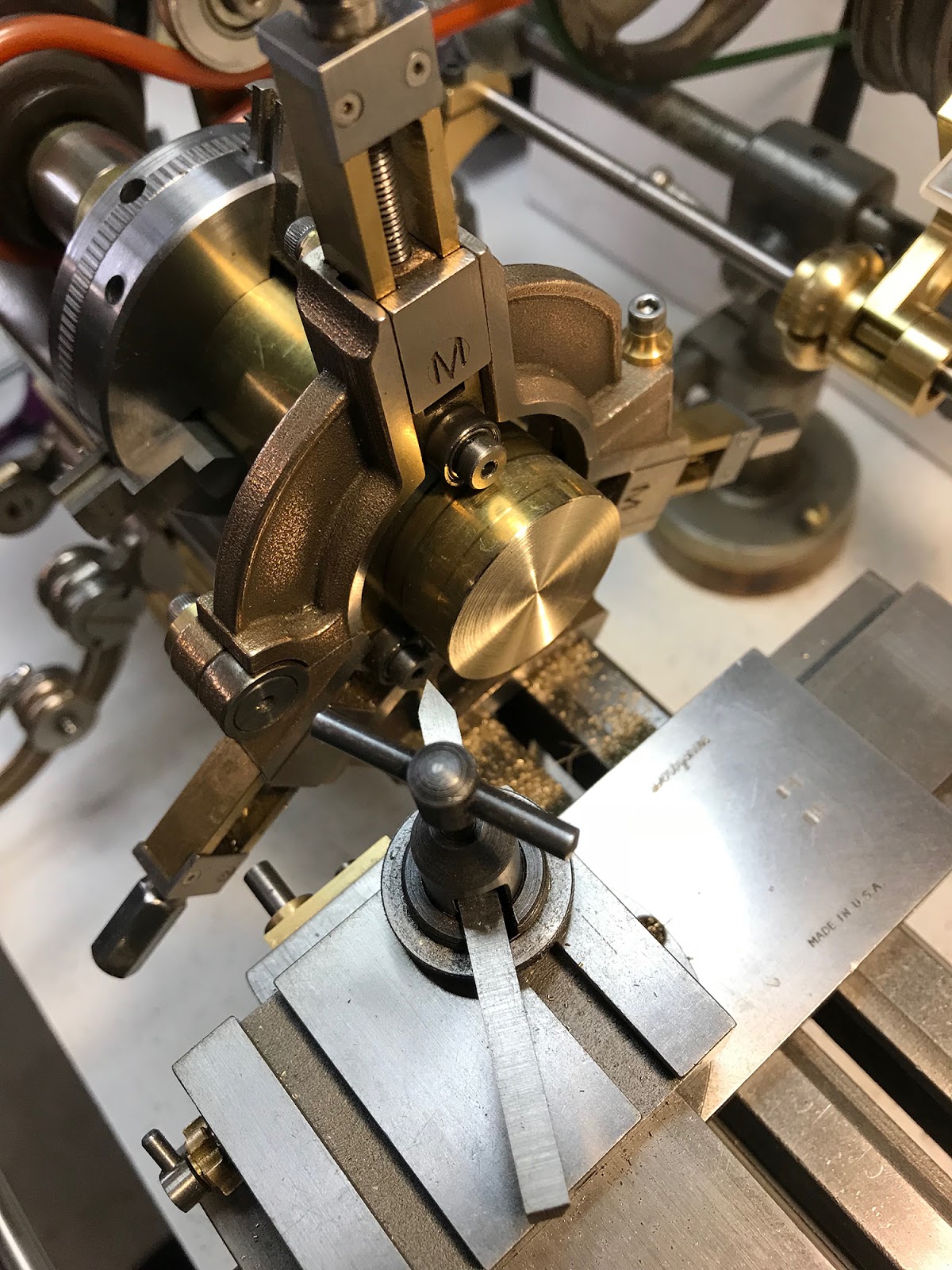

None of these require such massive material removal on such a small portion of the belt though. I use 36 grit to shape and 80 grit to finish shaping, then hone with diamond stones. Works good for me. Excited to learn about lathe tool grinding. Can you please recommend a source or plans for the fixture that you use.

It appears to provide accurate and repeatable angle settings. Thanks in advance. Home Clubs Forum About. The carbide tool made the cut but chatter was excessive. Speed was as low as I could reasonably go and the feeding force was very high. The finish is really ugly due to all the chatter and the chips are tiny and powdery. Reducing the depth of cut to 0. The HSS roughing tool did fair but there was a lot of chatter.

Speeds and feeds had to be adjusted almost constantly to make it this far. Finish is rough but not excessive for a roughing cut. Chips are tightly curled due to the standard side rake. Reducing the cut to 0.

The modified tool cut easily, speed was about RPM higher than with the other tools and there was no chatter at all. Finish is much better compared to the other tools. The chips look more like loose shavings due to the sharper included angle at the tip. Chips from the carbide tool, HSS rouging tool and the modified tool are distinctly different.

You absolutely cannot fake a chip. They tell you exactly what is going on at the tip of the tool. First, the grinder The bench grinder is the most commonly recommended tool for grinding lathe tools. As a tool grinder the belt sander is almost ideal: Belt sanders cut very fast and very cool when you use the right belt and a wax stick lubricant.

With their wide flat platens they allow for simple tool alignment so facets are easy to avoid. This is far, far, far better than trying to realign a tool to a narrow round wheel that requires frequent dressing. Belts are widely available, cheap, and do not require dressing, balancing, or conditioning. They also have a very good service life if used with wax lube.

Changing grits takes seconds and going from shaping to a mirror finish by stepping up through the grits takes a few minutes.

|

How To Make A Frame Cabin Wallpaper Jet Jwbs 14dxpro 14 Deluxe Pro Bandsaw Kit Mini Cnc Wood Carving Machine In India Express |

RUSLAN_666

14.04.2021 at 13:43:51

Lewis

14.04.2021 at 23:20:19