Laminate Wood For Turning Rod,14 Inch Undermount Drawer Slides With,Rockler Bench Vise Number,Marking Tools Woodworking Company - Test Out

Frogwood RHD5 is heavier but has excellent resilience with smooth cutting and finishing characteristics. I have the honor of producing 30 patriotic seam rippers for the Quilts of Valor Foundation. Great job Joaquin, thank you for your work for Quilts of Valor. I like Frogwood because it is easy to carve yet stronger than some of the laminates I have worked with in the past. Another big plus is how the colors don't run or mix with each other when varnish is applied.

The colors are great and I certainly will be buying more of it in the future! Amazing Absolutely love this blank Cant wait to make different pens with this wood. Awesome to work with and great quality.

People love it. I found working with FrogBlanks on the lathe very satisfying. No tear-out, as sometimes happens with laminated wood e. Can't wait to turn more, and apply them to other projects. Frogblanks turn well and finish great! Superbly crafted with no deficiencies.

Definitely a wow factor! Prompt shipping and really appreciated the fact partial sizes could be ordered rather than only the full panel options of some of FrogBlanks competitors. The RHD5 machined very well and the high layer strength left zero tear-out anywhere on my project. They don't expressly discuss the grain orientation problem, however the material on the differences in shrinkage in the radial and tangential directions makes it pretty clear.

DB- It's not clear whether the publication will successfully download on my slow 'net service. But I can say I've been reading and thinking about the subject for over 40 years. Per the fundamental radial vs tangential shrinkage diagrams that everyone "gets" in wood , the squares will all shrink to diamonds, long points radial or expand to diamonds long points circumferential whether they are oriented as drawn, or as you and I propose.

Also, contrary to that crazy guy's statement; more, or perhaps "heartier" heartwood is contained in the as grown orientation. To my view, there is less differential stress along the glue joint with changes in MC.

But since any effect described is somewhat mirrored by both orientations, I have to be open to the possibility someone did test and and maybe the results are inconclusive or even horrors! I am fairly convinced that if expansion is the major problem, the as-grown orientation would be better.

But Pete is considering shrinkage as the major issue. In that case, I am less confident. So I say it still needs an experiment. And it has to be 4 pieces. With pool cue shaft wood, some are arranging 6 to 8 pie slices with the grain all radial. I don't think it has been proven to be superior, given the vagaries of natural wood anyway. Even microlam shafts laid up flat from thin veneers are sometimes better, sometimes worse; and no doubt frustratingly both continue to warp.

Perhaps a diversion from the glue question, though since in those small sections it is seldom an issue. Stradbash liked this post. I tend to think that the fact that skilled craftsmen on this forum haven't reached a consensus re: grain orientation might suggest that there isn't an obvious best way. Re: which wood to use I favor hickory where shock resistance is critical hammer handle or ash if bending strength is critical peavey handle; straight grain is important!

Ash is typically more stable and should machine better. Hickory is Laminate Wood For Turning Gain heavier. Either way, I second third? If I faced this problem, I would do as Steve describes for pool cues. I would also use a stiff epoxy. The final result would change diameter slightly with moisture, but would be about as stable as a wood part can be.

I doubt that there would be problems with feeling the glue joints either. Here's my 2 cents - Either of the orientations are symmetrical, which should reduce or eliminate differential movement. And the parts are small enuf that movement should not be dramatic enuf to overcome a good glue joint. I think most problems with glue joints have much more to do with preparation of surfaces and moisture content than grain orientation.

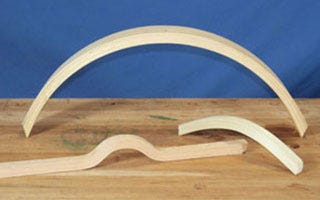

Keep the glued boards in woodworking vise until the glue dries out. Join another four boards with glue in the same way, then keep the whole structure in woodworking vise until the glue is dried out. The same procedure goes for making the next levels of boards follow the pictures. The only limit of your wood levels is the maximal diameter that you can achieve with your lathe, i. When you finish joining the boards with glue, and the glue is completely dry, put one board dimensions 40 x 40 x 30 mm in the middle of the whole assembly — this board will enable to fixate the whole structure into lathe.

Tighten up this wooden assembly into lathe and cut it by the desired curve. When you form a wanted shape of your object with lathe and cutting, make another wooden part dimensions 40 x 40x 20 mm , which will be a pedestal, and attach it with glue to the bottom of an object. This is not necessary for an object shown on Example 3.

Cut the 2 glass sheets dimensions 39 x x 3 mm , 2 glass sheets dimensions 33 x x 3 mm and 1 glass sheet for the bottom of an object dimensions 33 x x 3 mm. Join these sheets with silicone or some other adequate material. When you form this glass jar, you should check out if it leaks, then place it in the middle of the wooden vase.

|

Used 6 Inch Jointer For Sale Singapore Wood Lathe Spindle Turning 2x4 Scrap Wood Projects 40ml Woodworking Subscription Box Uk Us |

FASHION_GIRL

03.01.2021 at 21:23:45

Zaur_Zirve

03.01.2021 at 20:40:55

Koketka

03.01.2021 at 21:15:10

INSPEKTOR

03.01.2021 at 11:30:11

LEOPART

03.01.2021 at 12:48:34