Kreg Plunge Saw Table Of Contents,Woodworking Projects And Plans Free 02,Woodworking Shop Square Foot Use,Bora Wood Rack Instructions Quote - Review

JD Posts: Quote from: jussi on February 02, , PM. Quote from: Svar on February 02, , PM. RDMuller Posts: The original question was never really answered by an official source.

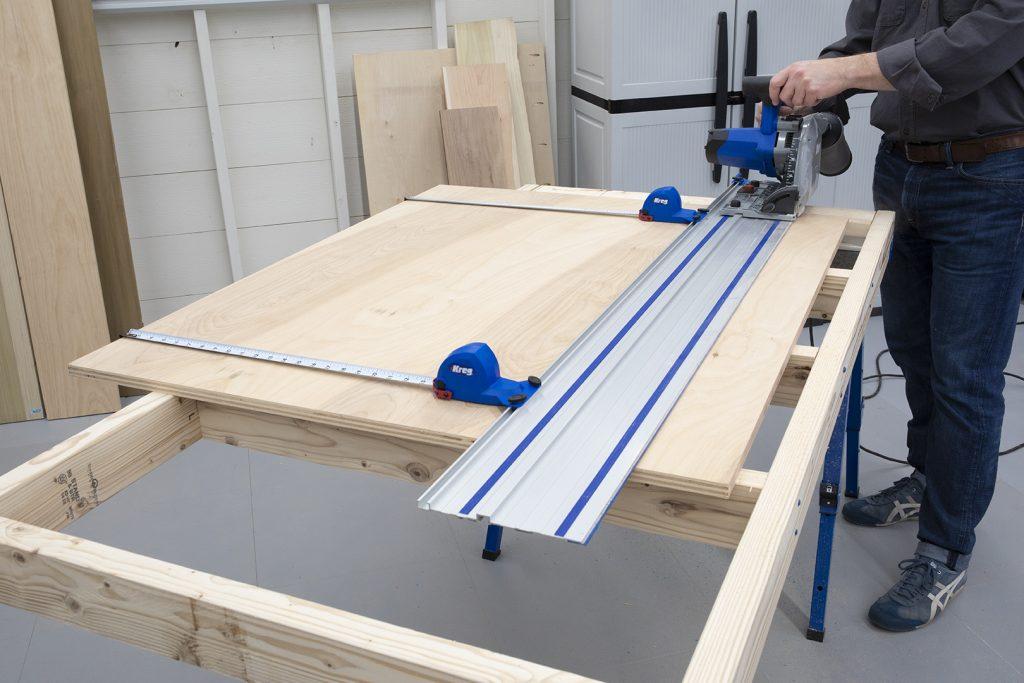

Does a Festool saw slide up and down the Kreg track? I sure hope so. Roseland Posts: I rather like this saw, particularly that the blade is on the left of the saw. This makes it easier for right handed people to see the cut, and to hold the saw when cutting parallel to the front of a bench from right to left. I also like the built-in kickback lock.

It seems they've put some thought into this product. Here's something from Toolnut. And I had asked Kreg about the usability of the entire top in reference to cutting. ChuckM Posts: If Kreg had the core objective to get the market to accept its track saws and not just its tracks, it certainly would want to design its tracks to be incompatible.

Its sales strategy. So it is a choice between Kreg and others, to a potential buyer. I see a lot of differences between them. Some even thought the Kreg looks more like the Mafell.

JimH2 Posts: From what I have read here the only reason for any interest in the Kreg rail system is because it must be cheaper than Festool's. While it would seem like an obvious decision to make their stuff compatible with others, it was not their goal or they would have 20mm holes in their cutting table. Kreg's goal is probably to undercut the market with a less expensive track saw and I suspect they have other tools in the works that use their track.

Different means locked in. I also think their customer base is different and they have a much larger retail footprint than Festool does. While it may be possible , Kreg makes no such claims, and does not recommend using the Plunge Saw with the tracks from other manufacturers.

Koamolly Posts: The spacing where the track connectors go on Makita tracks seem closer together than on the Kreg track.

Looking at Kreg it looks like there is room for two glide strips between extrusions, where Makita and Festool is basically one. Could be the pictures. Maybe the Makita or Festool saw will work on rail but blade will not line up with splinter guard but be offset outside of it. Quote from: Svar on February 04, , PM. Quote from: Koamolly on February 04, , PM. When you enter a contest or other promotional feature, we may ask for your name, email, phone, address, etc.

It is not recommended to use coarse-thread screws with hardwoods. Coarse-thread screws may cause hardwood to split. If the jig shifts during the drilling process, it can break the tip and damage your workpiece pocket holes.

Find the right Kreg Clamp here. We recommend that you glue your pocket-hole plugs in place. This will ensure that they stay in place during the entire life of your project. Find the right plugs for your next project here.

You will attach your deck board from both sides. Unfortunately, we do not have adapters for the Dust Collection Attachment.

Adapters for various vacuum sizes should be available at most local hardware stores. We appreciate and value our relationship and regret any inconvenience this decision may cause. Replacement drill bits can be purchased at www. For more information, call us at Monday-Friday, 8am-5pm CST or email us at technicalsupport kregtool. They are available in quantities of and Press down on the ratchet release and slide the clamp assembly all the way back.

Position the workpiece against the drill guide. Move the toggle handle to its full-down clamped position. Then, slide the clamp assembly forward until the pad contacts the workpieces. While holding the clamp mechanism against the workpiece, lift up on the handle until it clicks twice. Then, press the handle back down to the locked position.

To do this, release the lock-nut, rotate the clamp pad in or out, and test the hold by depressing the toggle. Repeat this process until you get a secure hold on the workpiece.

Then, retighten the lock-nut. Slide the Depth Collar towards the jig base and lock it in place with the included Allen wrench. Then, go to kregtool. Making your markings more visible can be accomplished in numerous ways, including paint, grease pen, white-out, and even fingernail polish.

Mix equal parts flour and water tablespoons should be adequate into a paste. Wipe away the excess paste with a very lightly dampened cloth. The paste mixture will harden over time.

Repeat if necessary. Place the stop-collar setting block on the jig base in front of the drill guide. With the step bit shoulder resting on the block, slide the stop collar onto the drive-end of the bit so it rests on the drill guide. Then, tighten the stop collar set screw with the included hex wrench. To fix this, take both sliders off, flip them over, and put them on opposite sides. Now, the lip is pointing up instead of down.

There is a mark on the bottom side of the jig to set your thickness with, just like you would in a normal application. These blocks slide on to the bottom of the Drill Guide Block. Depending on the thickness of wood you are working with, you will need to adjust the number of spacer blocks you use. Additional screws can be purchased in quantities of The spacer blocks are used with the Drill Guide Block to make it easier to use portably.

Also, the stop can easily swing out of the way to serve as a support for large panels. To use, simply place a plug into the tear-drop recess on the underside of the jig.

Then, press on the jig to firmly seat the plug into your pocket hole. They are a great choice for a wide variety of applications, including decks built with ACQ-treated framing.

For even more protection, choose Stainless. Kreg Stainless Screws provide the best protection against corrosion in the long-term. Deck Screws are offered in two lengths. Kreg deck screws use a 1 KTX square driver. Because of its larger head, this screw seats extremely well in a pocket hole. The SPS screw is a pan-head style. This smaller-diameter head works extremely well with hardwoods and with thin stock. The selection between fine and coarse will depend on the type of wood you are working with.

For softwoods like pine, you will want to use the coarse screws. For hardwoods like oak, you will want to use the fine-thread screws. Because of this, it is possible that once the plug is inserted into your pocket hole, it will protrude past the workpiece surface.

To eliminate any excess material and bring your plug to flush, we recommend using a flush-trimming saw or a flush-cut laminate bit in your router to trim off the majority of waste, and then sanding to flush.

Due to changes in climate and humidity, it is possible that your plugs have absorbed some moisture and swollen up, making them really snug or sometimes unable to fit. This will draw the moisture out, so they should fit in your pocket hole with no problem. Orders placed on the website are shipped FedEx. To specify a carrier, please call Kreg Customer Service at for availability and a price quote.

Kreg Tool Company honors a day money-back guarantee, less shipping and processing charges. For any returns, contact Kreg Customer Service directly at We currently ship to all 50 US States and many countries worldwide.

Freight rates are determined based on ship to country. Please call Customer Service at for assistance if assistance is needed in placing your order.

Box address. We apologize in advance for any inconvenience this may cause. We do not currently ship to Canada through our online shopping cart. Your refund will be issued in the same method your original payment, and may take up to ten 10 business days to be processed by your bank. Unfortunately, you will not be able to modify your online order once it has been submitted. Please call Customer Service at to change the order. This number is staffed Monday through Friday, 8am—5pm Central Time.

If you received a faulty item and need to exchange it for the same item, please email or call our Customer Service Team to expedite your exchange. If you would like to exchange your item for a different one, please email or call our Customer Service Team to expedite the return. Feel free to place another order online for the item you wish to purchase. You Kreg Plunge Saw Table Solution do not have to wait for us to receive the original item before placing the new order.

Please contact Customer Service by emailing customerservice kregtool. At this time, we do not accept tax-exempt orders via online shopping.

If you would like to place a tax-exempt order for resale, please contact our Customer Service Team at You may return any Kreg product that does not meet your expectations within 90 days of delivery for a full refund.

You should expect to receive your refund within four weeks of giving your package to the return shipper; but in many cases, you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper 5 to 10 business days , the time it takes us to process your return once we receive it 3 to 5 business days , and the time it takes your bank to process our refund request 5 to 10 business days.

You can track your order here. We will also send you a FedEx tracking number by email when your order ships. You can follow the progress of your shipment by entering your number on FedEx. Return labels provided by Kreg Tool Company are valid for domestic returns only.

In addition, if you use a shipping label provided by Kreg and your return is not the result of our error, the shipping cost of the returned item s will be deducted from your refund. Pack the items and packing slip securely in a box.

We are unable to re-ship orders that are returned to us as undeliverable. If you would like to re-purchase items that were deemed undeliverable, you are welcome to place a new order on our website. If you suspect your order cannot be delivered as addressed and you have not received confirmation of its return or refund after four weeks from the estimated delivery date, please contact us by emailing customerservice kregtool.

If you would like to pay by check, you must place your order by calling Customer Service directly at We will ship your product s as soon as possible once your order has been processed.

Please reference the chart below to estimate the number of days it will take to receive your order from the time you receive your email shipping notification. You may also track your order shipment online at FedEx. We are required, and do collect and remit sales tax in each state.

The tax, as it appears on your order confirmation, is estimated based upon the base tax rate for your state. Any local taxes will then be added to the total amount in your final invoice. Chances are, your order included one of our large machines. Any order containing a large machine will be palletized on a truck. As a result, our system generates two separate orders and sends you two confirmations. Incorrect Address — If the address in incorrect or outdated, the package is typically returned to us by the carrier.

Please double-check your address carefully when placing your order. Damaged Label. In rare cases, it is possible that the address label becomes illegible during the shipping and handling process, or that the carrier made a mistake and left the package at a different address than what was printed on the label. Failed Delivery Attempts — Most of our carriers make three attempts to deliver a package. If the driver feels it is best to obtain a signature and no one is present to accept the delivery after three attempts, the package will be returned to us.

Refused by Recipient — If a gift recipient is not expecting a gift, they may refuse the package if they believe it was sent to them in error. If you still want to send these items, you may want to let the recipient know that a surprise is on the way. We are accepting project plans that we have sponsored. If you are interested in being sponsored by Kreg, please visit kregtool.

Yes, you can use a panel bit with the Precision Router Table System. This is large enough for most panel-raising bits. Yes, the Precision Benchtop Router Table can be used with a router lift kit. The Precision Benchtop Router Table can be used as a jointer, with the help of its included jointing rods.

Insert the two jointing rods behind the fence face on the outfeed side. To adjust your Precision Router Table Fence opening for different-sized bits, loosen the screws that attach the face boards. Then, slide them open or closed depending on which bit you are using. You want the opening to be slightly larger than the bit itself. This gives you the best protection from injury, as well as the smoothest transition between the infeed and outfeed sides of the fence. If your Precision Router Table Fence catches while being moved, make sure that you are using only one hand at the clamp block to move it.

If you are trying to move it at both ends, it may jam and catch. The dust port hole on the Precision Router Table Fence is offset to give you Kreg Table Saw Fence Upgrade Weight the best suction, which allows for the most chip collection. This is accomplished by creating a vortex to suck the excess dust away from the bit. Please visit kregtool. All warranty information, if applicable, is located on the corresponding product page. If you have a question about warranty, please contact Kreg directly for warranty service or assistance.

Try searching a different phrase, or contact Kreg Customer Service to get answers fast. What is the maximum cutting capacity depth of the Plunge Saw?

What range of miter angles can be cut on the Project Table? What size blade does the Plunge Saw use? A few key differences include: The blade on a plunge saw is fully shrouded.

Where can I learn more about the Adaptive Cutting System? You can learn more about the Adaptive Cutting System on our dedicated education page: Conquer your cuts with the Adaptive Cutting System. Why are there two different sizes of Versa-Stops? Why does the Project Table use measuring rules with two different scales?

Why does the saw make a different sound when I release the switch? Why is the Plunge Saw blade located on the left side of the saw?

Why will my Plunge Saw move forward on the Guide Track, but not backward? Will my track saw system from another manufacturer work with the Project Table? Will the Plunge Saw work with my track from another manufacturer?

Will the Rip Guides and Parallel Guides work with my track saw from another manufacturer? Can I cut with the Guide Track in other locations on the Project Table besides where the track hinges place it? Can I purchase Guide Tracks in different lengths? Can I use other saw blades with the Plunge Saw? Can my Adaptive Cutting System be recalibrated without replacing parts? Can the Plunge Saw be used off the track? Does the Adaptive Cutting System require Kreg Plunge Saw Table One calibration? How do I find a dealer that carries the Adaptive Cutting System in my area?

How is the Adaptive Cutting System shipped? Each of these items will be in a separate box: Plunge Saw: Adaptive Cutting System accessories and replacement parts are packaged individually. How much adjustment do the legs have? My cut does not go all the way through my material, or it is cutting too deep.

There is a lot of play between the saw and track, how do I fix it? What are the dimensions of the Project Table? The project Table work surface measures What do I do if I cut through my table? What is included with the Project Table? Remove the clamp from the packaging and test the clamp pressure on your material. If you are happy with the pressure of the clamp, no further adjustment is needed.

Once open, turn set screw one-half turn to the positive for more pressure, to the negative for less pressure to adjust.

|

Mallet Hammer Silhouette 60 Pocket Hole Jig Sri Lanka Os Diy Wood Projects Pinterest Uk |

Juliana

07.09.2020 at 16:55:50

0503610100

07.09.2020 at 15:28:20