Jointer Plane End Grain Data,Makita 18v Biscuit Jointer Github,Cherry Wood Veneer Home Depot 24,Soft Close Drawer Slides Ikea Canada Yoga - New On 2021

All rights reserved. Designed and developed by Underscorefunk Design. This site uses affiliate links. Given this, please assume that any links leading you to products or services are affiliate links that we will receive compensation from. However, there are millions of products and services on the web, and I only promote those products or Jointer Plane End Grain 60 services that I would use personally. The Wood Whisperer abides by word of mouth marketing standards and holds integrity in the highest regard.

Should I ever be compensated to write, I will make full disclosure. I always give honest opinions, findings, and experiences on products. The views and opinions expressed on this blog are purely our own. Any product claim, statistic, quote or other representation about a product or service should be verified with the manufacturer, provider or party in question.

All content on The Wood Whisperer is copyrighted, and may not be reprinted in full form without my written consent. Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously. The cookie is used to store the user consent for the cookies in the category "Analytics".

The cookie is used to store the user consent for the cookies in the category "Other. The cookies is used to store the user consent for the cookies in the category "Necessary". The cookie is used to store the user consent for the cookies in the category "Performance".

It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Analytical cookies are used to understand how visitors interact with the website. It prepares the lumber to have that kind of texture. On the other and, a Jack Plane is a bit larger and ideal for early smoothing stages in straightening the wood for jointing. The edge grain is what you will see on the open end of the wood, while the vertical grain is on its face. Edge grain dictates the vertical grain, but the first one is sometimes too small to be seen by naked eyes.

So, most woodworkers prefer to look at the vertical grain. Lower angle means sharper for your plane blade; however, the edge becomes less durable.

Overall, 30 degrees bevel angle is ideal for a plane blade. Reading grains of wood is almost like a guessing game when it comes to inspecting the edge. However, you can increase the odds of wood planing with proper knowledge.

Avoid planing wood across the grain as much as possible because it can cause tear outs. It is about studying the board, listening and feeling your wood, and making mid-course corrections whenever needed.

Maybe, you are wondering where to buy woodworking tools and materials. Will you direct in the shop or maybe try purchasing differently, like in auctions? Will you sacrifice your money, as it Knowing the history of woodworking is significant. So why learn from the past? It allows you to innovate something and make a part of woodworking innovation. Woodworking started from Skip to content Planing wood may sound simple, but it requires proper grain reading for the right action.

What Is Wood Planing? How to Read Grain on Wood? Again, that's a thickness planer, which has the cutterhead pretty much fully-enclosed and self-feeds once you get it started.

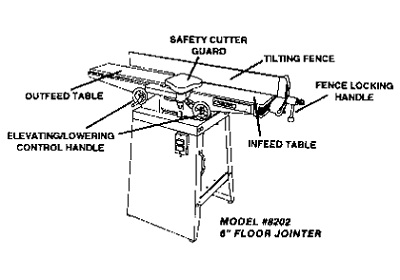

But you're talking about a jointer, which leaves nothing but the workpiece between your workpiece and the push pads that you hold with your hands to push the workpiece across the jointer. If you're doing this with individual endgrain strips, it seems like those would be even more likely to split. I'm sure you could find ways to limit your risk, for example, by using a power feeder or a heavy-duty jig, but it still doesn't seem like a good idea.

I wouldn't want my hands anywhere near the workpiece when something like this would be likely to happen. Trying to joint endgrain on a jointer sounds like a great way to wind up in the emergency room. That said, some people get away with using a thickness planer to take off very shallow bites e. If you want to try this it's important to have sharp knives and preferably a segmented cutterhead with sharp cutters to help against tearout, and to chamfer bevel the edges to help protect against blowout on the trailing edge You'll probably have better luck with a drum sander or router sled, though it's still important to take light passes.

It seems like everyone I know with a drum sander has a dent in the wall from a drum sander "incident. Definitely no. Granted, some species will be more prone to splitting across the end grain than others, but in general it's too dangerous. Don't joint the individual strips. Instead use a Jointer Plane End Grain Equation high-quality crosscut blade on your table saw when you make the crosscuts, and after you've glued up the board, use a router sled, sander, hand plane, or scraper to further smooth the surface if necessary.

Just glue a sidegrain hardwood border around it, run it through your planer lightly with sharp knives , then cut the border off if you want. There's always an easier way. Sign up to join this community. The best answers are voted up and rise to the top. Stack Overflow for Teams — Collaborate and share knowledge with a private group. Create a free Team What is Teams? Learn more. Edge jointing end grain cutting board strips with a power jointer Ask Question.

Asked 5 years, 7 months ago. Active 2 years, 1 month ago. Viewed 6k times. My questions are: Would the edge jointing go smooth across the grain, which is the resulting strips after the second set of cuts, like the ones in the below pic?

|

Best Bench Players 2020 3d Powermatic 15 Inch Planer Reviews On |

Vertual

04.06.2021 at 22:53:25

STOUN

04.06.2021 at 15:54:14

xXx_3X

04.06.2021 at 22:18:19

OSCAR_DELA_HOYA

04.06.2021 at 14:41:59