Sharpening V Carving Tools Gmbh,Jet 6 Inch Jointer Planer Zoom,Benchtop Drum Sander Industries Ltd,Hardwood Sanding Machine Uk - Downloads 2021

Most traditional methods focus on treating each side of the V as a straight Youtube Sharpening Lathe Tools Videos chisel, but there are several steps leading up to the actual sharpening that make it easier to get a sharp edge. Square up the end. Hold the tool vertically against a grit diamond stone. Move the tool up and down and from side to side until you see little flat areas where the sharp edges should be. You only want to remove the old cutting edge and return the tool to square. If not square, the tool will be difficult to sharpen.

Mark the flat areas with a permanent marker optional. Shape the side bevels. Support it with your index finger and apply pressure in different areas to direct removal of the metal. Maintain the angle and move the tool up and down and side to side.

Switch sides often. Use a grinder or sandpaper to bevel the back edge of the diamond stone and use the stone to shape the inside of the tool.

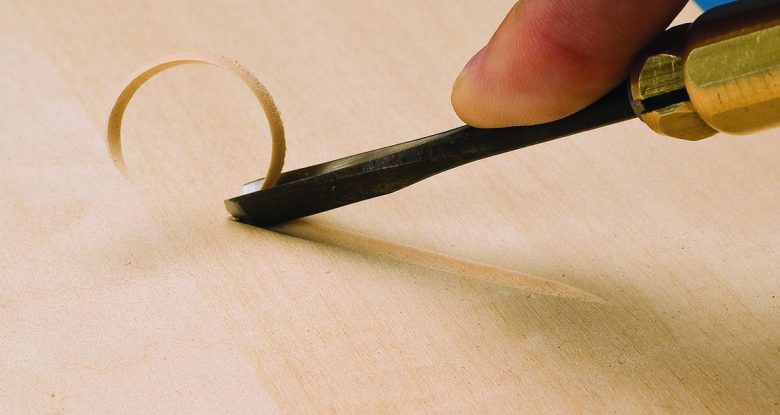

Clean up the edge. Work your way up through grit, grit, grit, and 1,grit diamond stones. As you sharpen, steel dust and slivers will obscure the edge. Force the tool into the endgrain of a piece of scrap wood to remove the dust. Work in stages. Remove a little metal, check the edge under a magnifying glass, and repeat until the flat spots disappear. Ask your admin to update your browser if you cannot install updates yourself. The technique for sharpening carving gouges and V-tools differ from tools such as plane irons and wood chisels with a straight edge — the steel is thinner and the edge angle smaller, which makes them more delicate to sharpen.

Often honing can be enough to touch up the edge. Since a carving tool often has a bent edge the sharpening takes place on a narrow and convex spot and the surface that is in contact with the grindstone is very small.

This means that the grinding pressure can become very high, even if you apply only a small amount of pressure on the tool with your hands. If you would sharpen more than necessary on a flat bevel, e. But if you over sharpen on a spot on a curved edge, the shape of the edge will be changed and needs to be re-ground.

This is also the case for V-tools — over grinding on one wing means that the entire edge must be re-ground. First question whether you need to sharpen your tool or if you should only hone it. This applies especially when working with small and delicate tools with a small edge angle. A slight over-grinding on a spot on these tools makes a pronounced pit or hollow on the contour of the edge.

The basic recommendation is therefore not to sharpen small and delicate tools, but to hone them on the leather honing wheel with Tormek honing compound. Sharpening on a grindstone is however required in the following cases:. Sharpening can be done either free hand or with jigs on the grindstone.

Using jigs is easier and gives you a better result as you can concentrate on where the edge touches the grinding wheel without needing to pay attention to the edge angle and the positioning of the tool, which is controlled by the jig.

Before you start sharpening, grind the edge to its correct shape. Viewed from the side, the edge should look like a straight line, the edge plane angle. The edge is now blunt, which clearly can be observed as it reflects light. You should see light reflecting along the entire edge. This blunt edge is called line of light and is a guide for you where to grind. By closely observing the line of light and only sharpen where it is thickest, you will achieve a perfectly ground edge.

Pay close attention so that when the line of light has just been ground away, you stop sharpening. Good lighting is important for all sharpening and honing work, but it is an absolute necessity when sharpening carving gouges and V-tools, since you must clearly be able see the line of light.

Use a flexible lamp and Hand Tools For Wood Carving position it close to the machine. Carving gouges and V-tools have wings. These lean more or less forward when the bevel lies flat on the wood.

The inclination can be described Small Electric Carving Tools 60 as the edge plane angle. This angle controls how the tool will cut in the wood. This recommendation is independent of the edge angle.

NOTE Grinding woodcarving tools on high speed grinders and belt grinders is absolutely not recommended! They grind too aggressively, which makes it impossible to control the grinding and the heat development draws the hardening of the thin steel. After sharpening, the bevel is honed to give it as fine a surface as Pfeil Set C Carving Tools possible. The remaining burr on the flute inside must also be honed off. The outside honing can be done free hand with a fine grit bench stone or with jigs on a rotating felt or leather wheel.

The inside can be honed freehand with slip stones or on profiled honing wheels. Honing is important, as a finer surface on the bevel and flute makes the tool cut more easily and also makes the sharpness last longer.

The surface left on the wood will also be smoother with a perfectly honed tool.

|

Fine Woodworking Square You Drying Wood For Turning Bowls Videos Drying Green Wood For Turning Radius Small Cabinet Hinges Lowes 4g |

256

06.08.2020 at 13:59:11

SEXPOTOLOG

06.08.2020 at 19:28:15

Elnur_Guneshli

06.08.2020 at 20:37:23

0111

06.08.2020 at 21:42:20

Vefa

06.08.2020 at 15:43:10