Pocket Hole Jig Tutorial 3d,Diy Shop Projects Kitchen,Used Furniture Hardware Drawer Pulls Online - Reviews

I had a thought when reading through it. Instead of modifying a drill bit, you might be able to use one of these, and adjust the size of the tube to accommodate the socket:.

Reply 4 years ago. Have you thought about making the bottom have a v groove to be able to drill them into round dowel like on chair rungs. I going to have to print one of these thanks. I have a Kreg Pocket hole jig kit with a lot of accessories as well. And you can buy replacement stepped drill bits fairly easy.

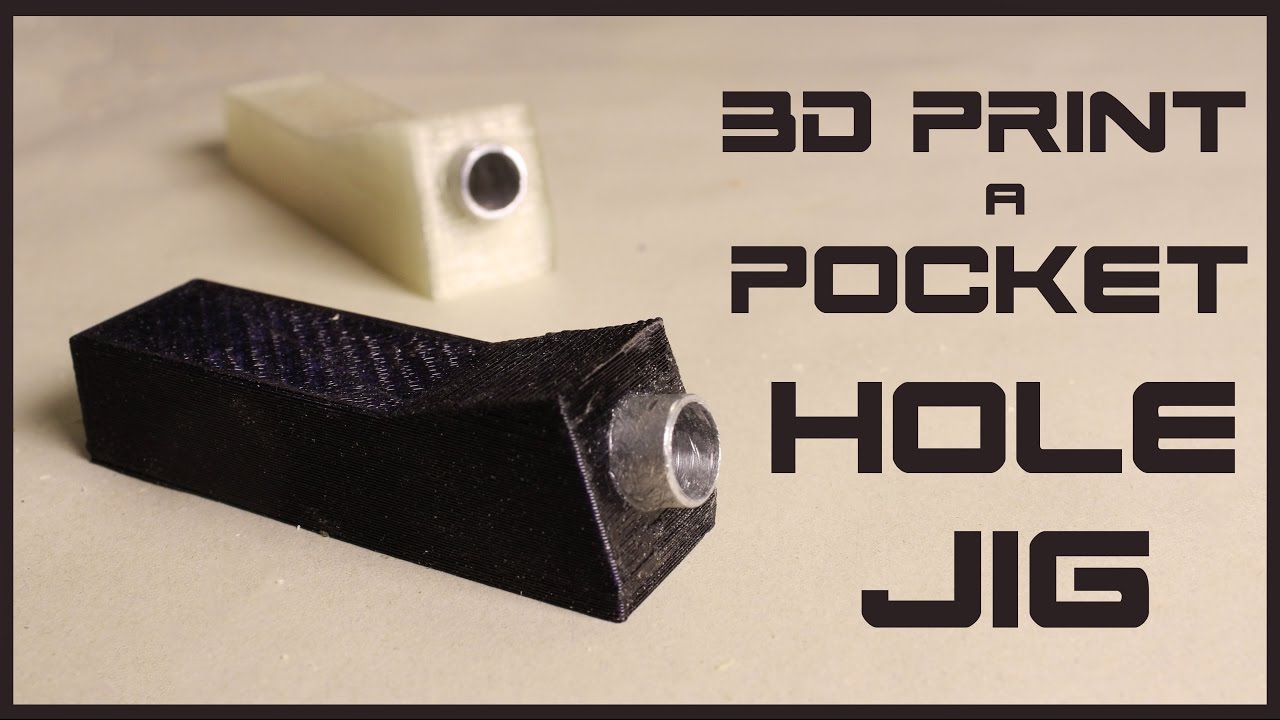

The jig you made looks good, but I would buy the very sharp stepped drill bits if it were me. Introduction: Make a Pocket Hole Jig. By Jakes workshop Follow. More by the author:. I made a seperate solidworks tutorial video: When I finished the model I export it as stl format and slice it with simplify 3d software.

Now, we need to cut a small piece of an aluminum rod, somewhere around from 2 to 3 cm I chamfer on side so It could slide in the jig more easily. I used a small rubber hammer to push it inside and the jig is pretty much Pocket Hole Jig Tutorial English finished. And the pocket hole jig is finished. Never assume. There can be variations between various stock. By taking a few seconds to confirm the thickness, you are saving your self a lot of potential frustration and wasted materials.

Seriously, it is life-changing! Just one pocket hole serves as a pivot point and you can easily twist the joint aka — not a strong joint. First of all — use pocket hole screws and NOT regular wood screws. They are specially designed to be used with pocket holes.

Pocket hole screws have threads only on the lower portion, while the upper portion not threaded. This helps the pocket hole screw to pull the joint tight together. Coarse screws are made for softwoods like pine and cedar. Plus, they are used with plywood. Fine screws are for hardwoods. I have only built with softwoods to date. An example of this is when you build a frame of a simple table.

In this case, the pocket holes are made on the ends of the board and the screws are driven into the edge grain of the other board. The pocket holes are made on the edge of a board the screws are driven into the edge of the adjoining board. An example of this is when I built the panels for the sides of the nightstand.

I get asked all the time, why do I make pocket holes on the outside of this chair rather than on the inside and hide them. It is true that you should try your best to put the pocket holes on the insides to hide them as much as possible.

However, there is an important reason for the exception to that rule. It is basically a hole drilled at a degree angle i. By putting the pocket holes on the outside, we are making sure the pocket hole screw goes into thicker material and minimizes splitting. This means that you need to set your drill accordingly. This helps account for the thickness variation — as drilling less is always better than drilling deep!

Clamps are not just like having a second hand, when correctly used, they help make the joints professional looking. I love Pocket Hole Jig Norge 3d the right angle clamp and the face clamp.

See a list of all my favorite Kreg Accessories that make woodworking easier and efficient! But wood glue makes the joint not just a lot stronger, it helps in preventing wood movement from moisture fluctuations that can cause cupping and cracks.

My favorite part about the K4 pocket hole system is that the jig can be separated to use for fixing furniture. Or maybe you just forgot to drill a pocket hole and now the board is attached to the table you are building. You can simply slide out the jig and clamp it where you need to make your pocket holes!

Kreg also has a Kreg R3 Jr system which is super affordable and can be used for building and fixing. There is also a mini jig kit that is perfect for fixing furniture or if you are making one-off pocket holes. I hope I answered all your questions about the Kreg pocket hole system. If you have any more questions, let me know!

Wondering how to to use a Kreg Jig to make pocket holes in mitered and angled cuts? Check out my guide to making pocket holes in mitered cuts! Read 7 more important Pocket hole tips including what to do when joining different thickness boards and the special setting when using plywood.

See 34 more project ideas — 37 Amazingly easy Kreg Jig projects for beginners. I want to join 2x4s cut at a 45 degree angle to form a 90 degree corner for the frame of a table. How do I set my Kreg jig to do that operation? You place the 45degree end flush to the bottom — creating a 45 degree angle with the bottom of the Kreg Jig.

I hope this helps. I am going to be doing a build with angles next week and will try to get some pictures added to this post. Anika — great video and I love your workbench — my next project!

I only wish my hardware store could cut 2 pieces the same size! Only once when a woman was working the saw were all the cuts I needed spot on. I have a small circular saw but am terrified to use it. Thanks Debi. I am glad you enjoyed it. Yes, getting the hardware store to cut pieces precisely can be quite a challenge.

I would recommend a miter saw instead of a circular saw. It is a lot easier to use and not too overwhelming. A miter saw is the first saw I started out with too. Nobody likes spam!

|

Makita Radio Xrm06b 40 Rockler Sprayer Jp Wood Countersink Set 7 11 Make A Frame For A Large Mirror On |

SKA_Boy

30.08.2020 at 19:40:31

050_475_55_05

30.08.2020 at 12:20:13

boks

30.08.2020 at 12:57:43

ASHKSIZ_PRENS

30.08.2020 at 21:34:34

SeXy_GirL

30.08.2020 at 16:41:14