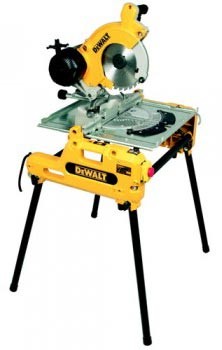

Miter Saw And Table Combo,Wood Countersink Bit With Depth Stop 50,Rifle 2018 - You Shoud Know

I've been looking at a lot of similar workbenches for a while, trying to find the right set up that would best utilize my woodworking tools and the space I have. I decided that was overkill for my needs, and probably beyond my skill set. This was the design that I followed almost exactly, making a couple adjustments to suit my needs, including the addition of power outlets.

The base frame is exactly 6' x 3' and legs were all cut at 30". You'll see I used 2x3's in less structurally significant spots to help reduce the miter saw and table combo weight. They worked particularly well for supporting the miter saw since 2x4's would have been too wide. You could spend more or less on other options but this has been working great for me. Mine were 5" in diameter, but smaller ones will save you some money. Electrical: 3 outlets, a one-gang and a two-gang box, about 5' of romex and a male plug for connecting it all to your extension cord.

Impact driver: I don't know how I ever survived without this thing. If you haven't invested in one yet, now is the time. Miter saw for cutting the lumber; I'm assuming you Diy Miter Saw And Table Saw Stand Combo have one if you want to make this table, but make sure it's one you're happy with because a replacement may have different dimensions same for table saw.

I love my sliding compound saw but it makes flipping the buggar over a little more complicated. Worth it to me, but be forewarned. Circular saw for trimming the edges and cutting out spaces for the table saw and miter saw. I built mine at 6 x 3'. If you want to get fancy with joints, go for it; butt joints worked well for me and it ended up plenty sturdy in my opinion.

For the legs you could also use 4x4's but I had too many scrap 2x4's lying miter saw and table combo that I needed to put to use. All my vertical boards legs were cut at 30". That plus the plywood top and the casters puts the final work surface at about 36", which is comfy for me at 5'10".

I built from the ground up since Miter saw and table combo knew I'd be making changes as I went. Make sure the spot you're working on is level mine wasn't, I later discovered. For the table saw support, I added 3 boards to the framing board that was set back a distance equal to the depth of my table saw's base 1st pic. I used clamps to hold the support boards in place tom make sure they were level when I added screws.

I trimmed down these vertical boards to get them out of the way of my table saw's miter saw and table combo, which clamps to the back edge of the saw. Alternatively, you could keep them 30" and connect to your table top when it's mounted.

Measure the distance from the top of your table saw work surface to its base. That will miter saw and table combo to be the distance that the two support boards are from the top work surface of the table, and don't forget to factor in the material you're using for your table top.

My sliding miter saw takes up a lot of space, so I ran the support 2x3's the entire width of the bench. I'll be honest, getting these measurements right was tricky and I had to redo them a couple times. First add a 2x4 on the top, backside of the bench, taking time to keep everything square. Check for notes in the pictures if you're not sure if I used a 2x3 or 2x4 in some spots.

All the legs, or vertical boards were cut the same size and then the horizontal boards were measured and cut as I went. If anything is confusing leave a comment and I'll add more notes to the pics. The top two 2x3 supports are flush with the rest of the bench top, and the second row of 2x3's is where it gets tricky. Like the table saw support, you'll need to measure the distance from the top work surface of your miter saw to the bottom of its base. That will be the distance to mount the second row of 2x3 support boards, so that when your saw is slipped in, its miter saw and table combo surface will be flush with the rest of the bench top.

Again, factor in the thickness miter saw and table combo your table top material. If you can't be perfect I wasn't eitherit's better to have your miter saw slightly higher than the rest of the table versus lower, in which case your work pieces will catch as you shift them around. This took me a few tries to get everything level and square ish. Easiest part of the project, so miter saw and table combo a beer; you've earned it!

I had these miter saw and table combo casters on another shelving unit that didn't really need to be mobile. Never pay money for that which can be salvaged. Craigslist is your friend. These 5" wheels are great cause I have a bit of a lip to run over, getting back into my garage and miter saw and table combo want to get hung up on it. If you're buying new, choose wisely as their cost can add up.

I'd say get 3" at a minimum if you won't be moving around much. At least two locking casters are a good idea if you'll be working on slopes. I used 3" lag screws that I had on hand for securing these. Sorry I didn't get more in-progress pics for this part, I was a little aggravated that I had to use a hand planer on some of the 2x4 framing since the spot I'd built it on wasn't quite level. After that nonsense was over, I started by securing the table saw in its spot with lag screws drill pilot holes, add washers if needed.

Next I double-checked measurements for the width and depth of the table saw surface. Mine wasn't perfectly centered since I left about 4" of table overhanging on the backside vs just miter saw and table combo on the front edge.

After marking out the cut-out area, I proceeded with the circular saw, cutting both sides and then finishing the corners and back edge with a jigsaw. Side note: I was able to make the cut-out space for the table saw and miter saw the same width. This will allow me to keep the piece removed for the table saw, and use it for an additional tool router, probably in the space where the miter saw normally sits.

I may end up cutting another square piece for my bench grinder as well. With the plywood in place around the table saw, from underneath the bench I marked the outside edges of the 2x3 supports for the miter saw. If your miter saw doesn't slide then it probably won't need to be as deep as the one I cut, but make sure you'll have space to reach all knobs and adjustments on your saw when it's in miter saw and table combo. After cutting about a foot in on the left and right sides I added clamps and Miter Saw Router Table Combo a scrap 2x4 to support the front edge while finishing my cuts.

As long as the support boards are square and parallel you shouldn't have any problems. But keep in mind that this piece will be upside-down when you mount your miter saw to it. Otherwise, if it's not perfectly square, it may not fit back in place when you flip it around.

In other words, attach the miter saw to the under-side miter saw and table combo the plywood piece you cut out. Once the piece is cut you'll be able to test fit it and see what I mean. I attached the miter saw with 3" carriage bolts, washers and nuts. If you're a perfectionist you could also route out a recessed area to get the heads below the work surface. Then I finished securing the table top with 2" screws and cut the excess material off with a skillsaw.

If you want to avoid drilling thru the top of the table you could also use a mixture of wood glue and brackets on the underside for a cleaner look. Things should be looking pretty good by now, and fully functional. I ripped them to fit the overall depth and then took measurements for cutting around the legs. I used a jigsaw and gave myself plenty of wiggle room; it's a workbench, not a cabinet after all.

I got excited and loaded it up with all my other power tools: planer, grinder, skillsaw, sawzall, compressor, sanders. It's probably too much weight for moving around frequently but I just miter saw and table combo having everything in one spot, and it cleared up so much space in my garage!

An optional step, but worth it after all this effort in my opinion. I mounted 4 outlets in a 2-gang box on the front of the table, so both saws could remain plugged in with two additional outlets for other tools. When picking the location I made sure it was close enough to the miter saw that I could leave miter saw and table combo plugged in while flipping it around.

This connected to two outlets on the backside, where the power comes in miter saw and table combo a male plug, strapped to the framing. This way I can bring an extension cord to the table wherever it ends up and then everything's powered. Thanks for reading my first instructable! Feel free to ask questions in the comments and I'll do my best to answer. Just want to comment on the plans for this workbench. I made this bench myself, painted it, adapted it slightly spent a couple months working on it over the summer between work and family commitments and was so proud of myself only to place both my table and mitre saws on the workbench to realize the design is not practical.

If I want to rip some boards on my table saw on the end the mitre saw in the middle is in the way unless I move it, which defeats the purpose of why I made the mobile work bench. I have to repurpose the wood to rebuild it so the saws are on opposing ends with a workspace in the middle. I had the top all lined up with the deck of the saws but never cut it and put it on since I have to change the design. Just a caution for others.

Reply 20 days ago. Did you guys miter saw and table combo a finish to miter saw and table combo table? BTW thanks for the design. I'm looking forward to building this. Looks great. Question 10 months ago. This is a great design and I have been having a blast making it! I am new to woodworking and I felt this was a great project to practice my skills with while still working on becoming a perfectionist when it comes to accuracy and leveling. Or is the fence extension not really necessary once you have the flat top in place?

Open to anyone's tips on this. Answer 4 months ago. Thanks, and sorry for the delay, but you're right, the placement of my table saw does limit a fence extension.

|

Free Woodworking Plans Gun Cabinet Review Sealing Wood For Turning 500 Build A Toy Car Store 2019 |

GATE

04.04.2021 at 22:29:52

shakira

04.04.2021 at 13:40:10

help

04.04.2021 at 16:38:53