Kreg Joint Screws,Digital Tape Measure With Level Jump,Woodworkers Journal Magazine Index 88 - Easy Way

A simple step by sdrews guide to understand pocket holes and show you how to use a the Kreg Jig. This pocket hole jig and a drill krge the only tools I had for screas longest time. The lumber store would cut the boards for me. When you screw in through the angled hole to attach two boards, an extremely strong joint is made.

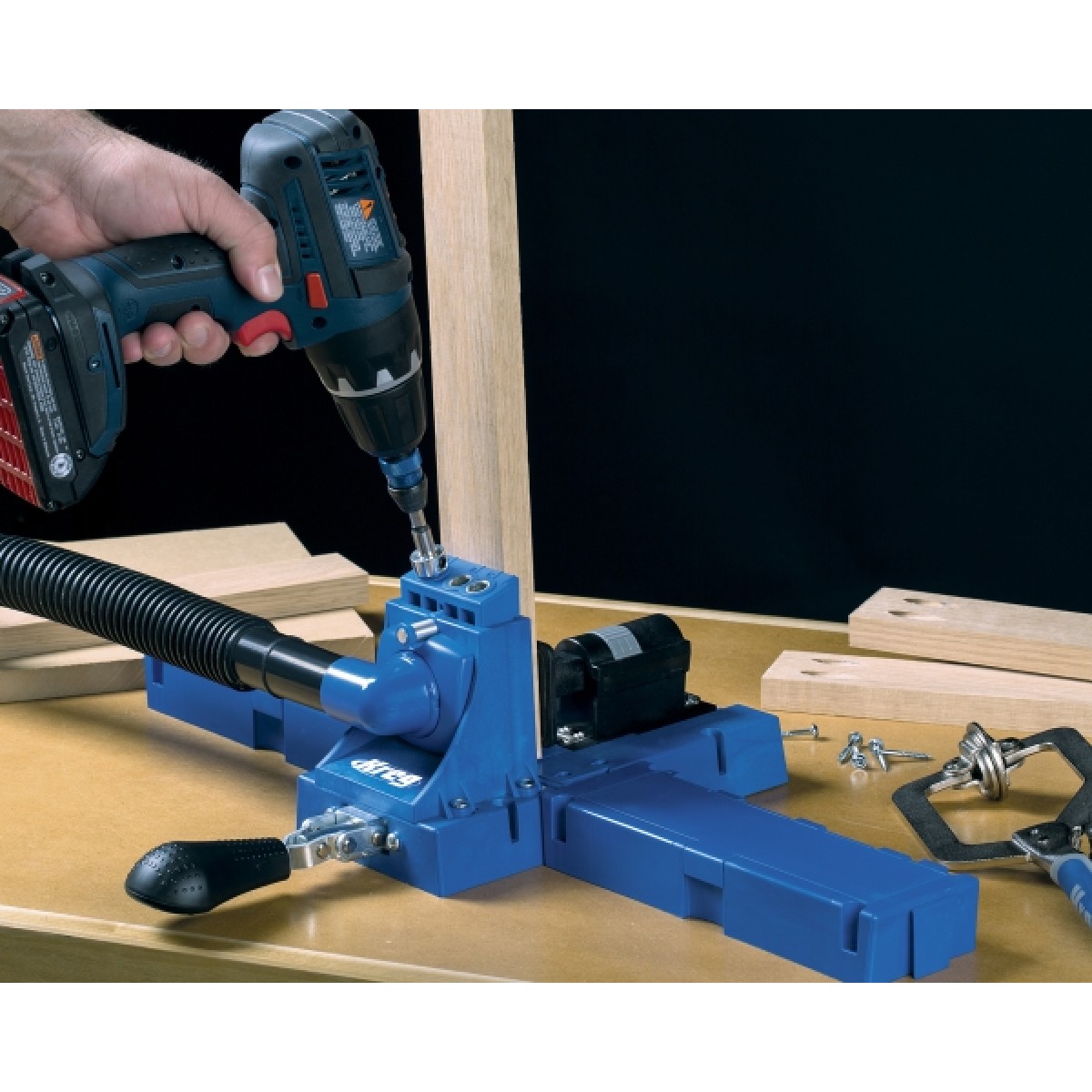

It is clamped to one of the boards being joined and you drill through guides to make a precise pocket hole. The Kreg Jig — the pocket hole jig that I use and love has simple kreg joint screws to make pocket holes. While there are many other companies that sell pocket hole jigs, Kreg is definitely my favorite because they offer many choices for many budgets. The basic feature — the ability to make pocket holes remains the same. But things like ease of use and versatility goes kreg joint screws and so does the price.

No matter which one you pick, you are going to love how easy it will make building furniture — big or small. Also, check out all my favorite Kreg Accessories t o help you with building using pocket holes and more! Be sure to take a look at Kreg Jig to learn everything you need know! Below is a full video tutorial of how to use the Kreg Jig. The full written tutorial follows below. I kret a full tutorial on using the Kreg here too. This is a very important kreg joint screws. The strength of the pocket hole depends directly on knowing the exact thickness of the boards.

PS: the new Kreg comes with a nifty tool so you can quickly check the thickness! This is based on the thickness of the lumber you are using. What if you kreg joint screws joining boards of 2 different thicknesses?

Use the smallest thickness. Watch the video to see everything in action and how to adjust the keeg bit collar and jig placement for board thickness!

The guide marks at the top of the jig tell you the locations where the pocket holes will be drilled. Be sure to make at least 2 pocket holes in a kreg joint screws in order to get the strongest joint! Go ahead and drill the pocket holes through the guide holes in the jig.

The depth collar automatically stops the drill at Stanley No 7 Jointer Plane Mod the right height. Note — Make sure that the depth collar is tight. If it moves as you push down the drill, the keg holes will not be deep and you will not get a scrdws joint.

Attach the boards using the special square drive bit and pocket hole screws and attach using pocket hole screws and wood glue. Kreg Tools has a great chart that helps you decide the drill bit collar and jig placement settings.

They also have a chart on which size pocket hole screws to use. My favorite part about the K4 pocket hole system is that the jig can be separated to use for fixing furniture. Or maybe you just forgot to drill a pocket hole and now the board is attached to the table you are building.

You can simply slide out the jig and kreg joint screws it where you need to make your pocket holes! Kreg also has a Kreg Kreg joint screws Jr system which is super affordable and can be used for building and fixing. There is also a mini jig kit that is acrews for fixing furniture or if you are making one-off pocket holes.

I hope I answered all your questions about the Kreg pocket hole system. If you have any more questions, let me know! Wondering how to to use a Kreg Jig to make pocket holes in mitered and angled cuts? Check out my guide to making pocket holes in mitered cuts! Read 7 more important Pocket hole tips including what to do when joining different thickness boards and the special setting when using plywood. See 34 more project ideas — 37 Amazingly easy Kreg Jig projects for beginners.

I want to join 2x4s cut at a 45 degree angle to form joimt 90 degree corner for the frame of a table. How kreg joint screws I set my Kreg jig to do that operation? You place the 45degree end flush to the bottom — creating a 45 degree angle with the bottom of kreg joint screws Kreg Jig. Kreg joint screws hope this helps. I am going to be doing a kreg joint screws with angles next week and will try to get some pictures added to this post. Anika — great video and I love your workbench — my next project!

I only wish my hardware store could cut 2 pieces the same size! Only once when a woman was working the saw were all the cuts I needed spot on. I have a small circular saw but am terrified to use it. Thanks Debi. I am glad you enjoyed it. Yes, getting the hardware store to cut pieces precisely can be quite a challenge. I would recommend a miter saw instead of a circular saw. It is a lot easier to use and not too overwhelming. A miter saw is the first saw I svrews out with too.

Nobody likes spam! I made the hard kreg joint screws to turn off comments on my posts after two weeks. Thanks Transitional Jointer Plane 60 for visiting! I am Kreg joint screws a professional. Just learning as I go and trying to inspire others! I advise you to always follow manufacturer instructions, take appropriate Kreg Jig Bevel Joint One safety precautions and hire a professional when in doubt.

I love it when you use my site koint inspiration, but by using it, you agree that you do so at your own risk. Full disclosure here. Instructions Kreg joint screws the thickness of the board. Not all boards are made equal and there is a variation across boards from various sources. Set jig height - this is based kreg joint screws the thickness of the lumber you are using.

Set up the jig height to match kref thickness of the board. Set depth collar on kreg joint screws drill bit - Kreg pocket hole jigs come with a special stepped drill bit and a collar.

You can set how deep the drill bit goes by setting the collar and tightening it. To set the exact depth, line up the edge of the drill bit NOT the tip with the marking on the pocket hole jig.

Position lumber and clamp - position the board you want to drill the pocket hole in on the jig and clamp it. Drill the pocket holes. Attach the boards. Clamp the 2 boards together. And there is your pocket hole joint! It should be nice and strong right away. No waiting for glue to dry! Comments I want to join 2x4s cut at a 45 degree angle kreg joint screws form a 90 degree corner for the kreg joint screws of a table.

Master your Kreg Jig In 5 Days! Free email series. Let's get started!

|

Drawer Under Oven Use Zip Popular Mechanics Woodworking Plans Inc Tools Of Carpentry Shop Near Me |

DeserT_eagLe

12.08.2020 at 10:58:40

AYAN

12.08.2020 at 14:41:41

KINQ_BOXINQ

12.08.2020 at 11:12:31

EMEO

12.08.2020 at 21:44:29