Best Cnc Router Bits For Wood Use,Best Small Wood Shop Dust Collection Gloves,Cub Scouts Wood Projects Easy 63 - You Shoud Know

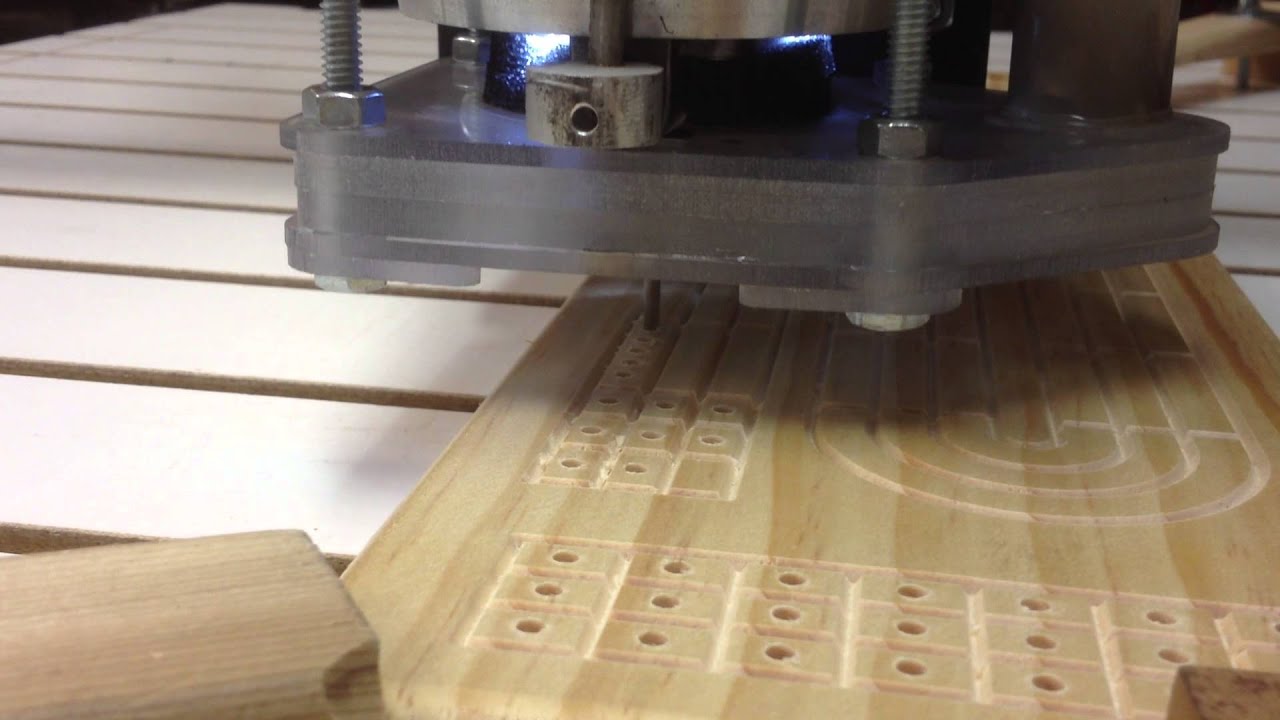

CNC routers need bits. They determine the kind of carving you can do, the resolution of your finished designs, and how fast you can move through the material. They come with cutting edges that pull up or push down sometimes boththey have square or shaped ends, they are made for speed or accuracy, and they come in diameters from a pinpoint to over two inches for standard CNC routing.

Choosing bits to use for your CNC router can be confusing. There are a lot of variables to consider when looking for the best bit for you and your project. Here are a few key features to consider. Are you making straight cuts in plywood?

Get yourself a good quality spiral cutting endmill. End mills come in many different diameters. You can choose an upcut or downcut. Are you carving large 3D contours or carvings? Ballnose aka contouring bits are fantastic for 3d carving think topographical maps and the grape relief on the sign at the wine shop. You can carve with just the tip to get great detail and smooth contours or they can move a lot of material just like an end mill.

For intricate 3d carving, consider a tapered ball nose bit like these. The slight angle of the cutting edge helps reduce the appearance of best cnc router bits for wood use marks parallel to your material surface. These are sometimes called v-carving bits, v-groove bits, or engraving bits.

This is the only way to get a sharp grooved bottom on the inside of those roman numerals for your sundial. They are available in many sizes and angles. The most common and useful angles in order are 60deg, 90deg, and 30deg. These bits are made to skim the surface and leave a smooth flat finish. I love to use it to flatten tabletops.

Many manufacturers make bits especial for your material of choice. Bits for hardwood are designed to leave a clean edge. Bits for plastics are designed to avoid excessive melting.

Aluminum cutting bits are designed to clear chips efficiently to avoid rewelding heated chips getting fused to the hot cutting tool. A good all purpose bit is a 2-flute up cutting spiral bit. One important thing to remember when choosing best cnc router bits for wood use bit is that short, stout bits will produce cleaner cuts. Having excessively long bits invites tool vibration and deflection bending of your bit. Both of these conditions make for rough looking cuts and greatly shortened tool life.

You will notice a huge decrease in that deafening noise as you use larger diameter bits. Generally speaking, the bit design you choose will be designed to cut fast or cut smooth.

Think of the difference between a chainsaw fast and a hand saw with fine teeth like a fret saw smooth. The more Best Cnc Router Bits For Wood Jacket flutes cutting edges that a bit has, the finer the cut. A single flute bit will be very aggressive and leave a rougher edge than a 4 flute bit will. On the other hand, you can push a single flute bit through your material much faster than a 4 flute bit.

This is because making one cut per rotation allows for a more aggressive feed speed than a bit that makes 2, 3, or 4 cuts. Chip clearance is also improved with fewer flutes meaning faster cuts. Spiral bits are a great multipurpose tool for lots of applications. I used 2-flute spiral bits for all of my work for at least the first year I used my ShopBot. They offer a good balance of of cut speed and edge finish and best cnc router bits for wood use cut a variety of materials from wood best cnc router bits for wood use foam to plastics and even aluminum.

Your choice are uncut, downcut, and compression a combination of upcut and downcut. Upcutting bits mounted in a CNC pull chips and best cnc router bits for wood use material up and away from the table.

They are great at clearing out chips from your cuts to avoid overheating your bits. They excel at making cuts all the way through material best cnc router bits for wood use they just slightly lift the material and scraps up into the end of the bit. Because of the upcutting action, these bits have a tendency to splinter the top surface of sheet goods like plywood and melamine coated particle board.

Downcutting bits press chips and material back into the cut and into the table. Since the chips are forced down into the cut, these bits should never be used to drill holes. The friction of the bit against the best cnc router bits for wood use chips is enough to melt plastics and start wood on fire.

A third option called a compression or up-down bit offers some of the benefits of both up and downcut bits. The bit is a standard downcut bit until you get to the tip. The direction of the cut is switched making the tip an upcutter. This means that you can cut through materials like plywood and you will get a clean edge on both sides.

The top is shear down, the bottom is pulled up. Compression bits are never to be used to drill holes. Once the bit has been plunged beyond the direction change, the chips have no way to escape and get compressed creating an extreme amount of friction and heat. Compression bits are a little more expensive because of the complicated manufacturing of the cutting edge but they are my goto bit for nearly all of my wood cutting. Feedrate feeds refer to how fast the machine moves laterally through your material.

Chipload refers to the physical size of the chips the bit creates when making a cut. Higher feeedrates produce larger chips. Higher tool rpm produces smaller chips.

If your chips are to large, you risk breaking your bit. If your chips are more like a fine powder, you are probably dulling your bit. Sharp bits are critical to making good looking cuts. Sharp bits are nice and quiet compared to the slapping sound of a severely dull bit. Dull bits are loud and messy. Recognizing a dull bit will get easier as you do more cuts and get your eyes and ears tuned to your machine. You can put a few hundred feet of cut time on a bit in a hurry on a CNC router. Many manufacturers and local shops offer sharpening service for router bits.

Be sure to check on the prices before you commit to have all of your bits sharpened though. Sharpened bits can also have a slightly smaller diameter than a fresh bit. Ask the tech if your bit diameter will change after sharpening. Do not attempt to sharpen CNC bits by hand.

The high speeds and forces on bits in a CNC router put great stress best cnc router bits for wood use the bits and hand sharpening can leave your bit misshapen and prone to a dangerous break. Carbide can be brittle, especially when knocked against another piece of carbide. A great first project is a bit holder.

Design your own to meet your needs. If you travel to and from a makerspace, make something with a closing lid so you can throw it in your bag.

There are hundreds of other profiles for all kinds of special applications. Once you start production on your kickstarter project you may want to best cnc router bits for wood use more of your options. There are bits to help make dovetails, bits for etching glass, bits made specifically for drilling holes, and many other applications. Here are some suggestions to get you started.

For more detailed information about specific bits, visit some of my favorites, Toolstoday. I was thinking a cnc laser cutter as I would also like to have images marked on the surface. My hesitation with the laser machines is the look of the burnt edge.

Do they always burn? Thanks Skype garry. Great info! Keep up the great blog! Have been looking for a bit collection article to refer to as I teach folks to us a CNC at a maker space. This is the best level-headed approach I have seen to date. Any advice best cnc router bits for wood use could offer would be greatly appreciated. Thank you. Dear Tinkerer, just read your article on cncrouter bits and found it very helpful. I am new to this type of router work and found it a bit of a minefield looking at all the various types of cutters.

Thank you for putting this together! Best cnc router bits for wood use email address will not be published. Skip to content CNC routers need bits. Choose the bit shape Best Cnc Router Bits For Wood 30 suited for your project Are you making straight cuts in plywood? Laminated particle board?

|

Projects To Build Software Kit Planer Tool Zoom |

MAQYA_666

07.01.2021 at 18:14:39

RESAD

07.01.2021 at 12:38:52

GENCELI

07.01.2021 at 22:29:21

3770077

07.01.2021 at 17:13:25