Uses Of Cnc Router Machine Id,Top Ten Router Tables 84,Spear Point Marking Knife Effect - Downloads 2021

What is a CNC router machine? This would always be the first question to come up when we first heard this kind of CNC machine.

In this CNC Router machine buying guide, we mainly including issues as follows:. Whether you are going to get involved in the field of CNC router machines or you are already in the field of CNC machines, this article about the knowledge of CNC router machines will definitely help you to understand Uses Of Cnc Router Machine the CNC router machine and purchase it. The Blue Elephant editor will share CNC router machines from the aspects of machine definition, processing advantages, machine types, machine core components, machine processing materials, application industries, etc.

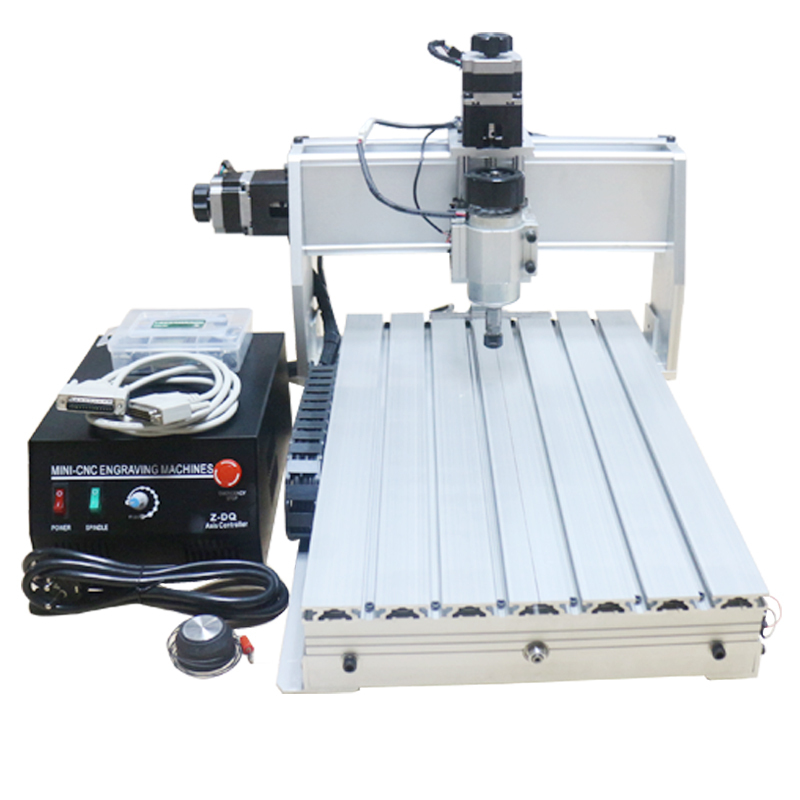

The better you know the machine, the better you can choose and use the CNC router machine. And uses of cnc router machine id is always be used for engraving various materials, such as wood, Acrylic, PVC board, MDF, marble, rubber board, plastics, glass, and foams, crystal, etc.

Relying on the advantages of complete types, wide application range, complete functions, high processing accuracy, fast production efficiency, and simple operation, wood engraving machines are loved by more and more users.

In addition to the large demand in the domestic market each year, more CNC wood router are exported to various foreign countries. Learned what is a CNC router machine, But why we need it?

What are the CNC router machine advantages? Compared with simple hand-craft:. It has the advantages of low cost, simple operation and convenient maintenance. This CNC wood router has the ability to perform movements around three different axes such as X, Y, Z axes simultaneously.

CNC Wood Router. Design and typeset by special engraving software, and control the CNC wood router through the controller to generate X, Y and Z axis engraving paths to complete the processing of the materials fixed on the workbench, to achieve the user's various processing requirements for the work piece. This CNC wood router mainly performs plane engraving on different plates. If you are just flat machining on some boards, this CNC wood router is definitely your ideal choice.

It is worth mentioning that the common three-axis engraving machines on the market also include multi-head engraving machines, multi-process engraving machines, etc. This type of CNC wood router can meet the tool change requirements during processing without manual involvement. Compared to traditional manual tool change production methods, this type of woodworking CNC router machine has a separate tool magazine with different tool heads.

It can be controlled by a computer program to automatically change the tools needed without stopping work during processing. Therefore, different processing requirements such as cutting, hollowing out, grooving, punching, slotting, and milling can be completed at one time, which can save time and greatly improve processing quality and production efficiency. Therefore, this type of engraving machine is the first choice for large-scale enterprises.

The spindle of this type of 4 axis CNC engraving machine can swing left and right, so the spindle can approach the work piece from multiple different angles and effectively process three effective machining surfaces.

Therefore, it can not only realize plane engraving, but also 3D engraving of irregular work pieces. In addition, this type of CNC wood router fully utilizes the geometry of the tool, controls the angle of the force, reduces the vibration of the force, and extends the service life, enhanced processing stability, and improved processing accuracy. Therefore, the four-axis CNC wood router can realize the processing of three-dimensional work pieces such as keel, Guanyin uses of cnc router machine id, Buddha statue, Roman column, gourd and so on.

If you have a variety of processing requirements such as common work pieces such as 3D work pieces, complex work pieces and irregularly shaped work pieces, this 4 axis CNC router can meet your diverse processing needs. Rotary axis CNC engraving machine is also called 4th axis CNCwood router who refers to these wood carving machine with rotary device. And it mainly processes cube or cylindrical work pieces.

CNC router with Rotary Device on working table. During the processing of the rotary axis CNC wood router, it is not necessary to repeatedly rotate and process the work piece manually to reduce the number of clamping times and complete the processing of the work piece at one time.

Compared with ordinary CNC wood router, rotary axis engraving machines reduce manual workload and improve production efficiency. In addition, since the tools of the rotary axis can be processed in layers, it is possible to ensure higher processing quality.

Stone engraving machine is specially designed for a variety of stone processing. Judging from the processing path, it has the same processing path as ordinary engraving machines. With embossing, lettering, hollowing out, cutting, seamless stitching, surface treatment, desktop milling and other processing functions. Stone CNC Router with multi-spindle. This type of engraving machine is mainly suitable for the processing of various types of hard materials such as Uses Of Cnc Router Machine Quota stone, metal, jade, crystal, wood, artificial materials, synthetic materials, etc.

Therefore, uses of cnc router machine id is suitable for the fine processing of smaller carved surfaces, such as the surface treatment of badges, sand table models, and crafts. The feature of small volume has particularly obvious advantages in packaging and transportation. The packaging and transportation are convenient, which uses of cnc router machine id saves users more costs to a certain extent.

If the motor power of the mini Uses Of Cnc Router Machine Youtube engraving machine is upgraded, this type of engraving machine can also be used to produce crystal characters, various types of advertising signs, and irregular plate cutting.

With its compact structure and small footprint, so easy to move and use, Mini CNC engraving machines are popular with woodworking enthusiasts and the advertising industry. This type of 5 axis CNC router has the advantages of high technology content and high machining accuracy, and is specially used for the machining of complex curved surface work pieces.

At present, the 5 axis CNC machine is the only means to solve the processing of impellers, blades, marine propellers, heavy generator rotors, steam turbine rotors, large diesel engine crankshafts, etc. In addition, such uses of cnc router machine id control equipment has a significant influence in the aviation, aerospace, military, scientific research, precision equipment, high-precision medical equipment and other industries.

And compared with ordinary CNC machine, this type of foam CNC router has a larger processing size and processing stroke.

Foam CNC router. Especially in the mold industry such as automobile foam molds, gypsum molds, paraffin molds, large ship wooden molds, aviation wooden molds, propellers, and train wooden molds, this type Uses Of Cnc Router Machine Github foam CNC router is very popular.

There are two processing sizes of common CNC router machines. One is the processing size of small format, and the other is the processing size of large format. Generally, the size of uses of cnc router machine id small format CNC wood router includes:. The engraving two-color plate is the most basic application of small format CNC wood router, which avoids unnecessary waste.

Large-format engraving machines include:. The feeding widths of the engraving machines of the above models are more than mm. The CNC spindle is an electric spindle that can be processed at high speed, which can be used for high-speed engraving, drilling and milling, drilling, etc. From the perspective of cooling methods, common spindles on the market include water-cooled spindles and air-cooled spindles.

Water cooling spindle adopts water circulation to cool the heat generated after the spindle rotates at high speed, which has the advantages of good cooling effect, low noise, long service life and high accuracy. Air cooling spindle is cooled by fan cooling, which has uses of cnc router machine id advantages of simple operation, convenient maintenance and low cost. No special maintenance is required, so maintenance and use costs are lower.

Uses of cnc router machine id air cooling spindle is suitable for users with shortage of water resources.

Of course, it is also an ideal choice for winter processing, especially for users in the north. The motor is an important component of the computer controlled wood router, and its performance has a crucial impact on the performance of the computer engraving machine.

Motors are generally divided into two categories including precision machining motors and high-power cut-off motors. The characteristics of precision machining motors are low noise, high speed, high precision, suitable for machining extremely fine work pieces, such as stamps, nameplates, badge gifts, etc.

This type of motor is usually a high-speed variable frequency motor with low power, generally below W. The disadvantage is that the ability to cut thick materials is poor, and it is not suitable for cutting thick materials.

High power cutting motor, mainly used for cutting and engraving. It is characterized by high power and strong cutting ability, especially suitable for cutting characters and three-dimensional characters.

Of course, it can also make badges, nameplates, seals, etc. The table of the CNC wood router is mainly used to carry different processing work pieces.

Different work pieces of different materials and shapes need to choose different processing tables. The aluminum T-slot uses of cnc router machine id table is fixed with fixtures to ensure that work piece will not shake during engraving. With the features of low cost and flexible method, it is suitable for work pieces with irregular shapes or difficult to fix work pieces. It can be divided into six sections and eight sections for vacuum adsorption, which can enhance the adsorption function even more.

Opening the vacuum valve, the engraving plate will be directly fixed, which has the advantages of convenient loading and unloading, saving time, high efficiency, and fast speed. It is suitable for wood door processing and large-scale plate engraving. The main function of the control system is to execute computer software commands and control the uses of cnc router machine id of the inverter and driver.

Commonly used control systems for woodworking engraving machines include handle control and computer control. This method of using the handle uses of cnc router machine id has the following advantages.

No need to connect to a computer, it can save space. Simple operation, it uses of cnc router machine id easier to learn and master. After uses of cnc router machine id and restart, the machine has the function of automatic carving, which saves the tedious manual point matching and improves work efficiency. The failure rate is lower and the machine can run more smoothly. Uses of cnc router machine id computer-controlled method can not only preview the processing effect, and you can see the processing trajectory at any time, but also can correct the program loading errors during the operation in time.

Each function is displayed on the control panel, which is very convenient to operate. Rail is a device that holds, holds, guides, and reduces friction of a moving device or device. Common installations include round and square rails. Round rail has the advantages of low cost, short production cycle and easy installation, which is suitable for small-format fine carving, especially suitable for simple relief carving.

With the advantages of strong load capacity and accuracy maintaining ability, stable operation, low friction resistance, high positioning accuracy, and good reproduction,the square rail not only guarantees the high-speed and high-quality operation of the engraving machine, but also maintains high precision for a long time.

So it is suitable for large format fine carving, and it is ideal for stone CNC wood router, woodworking engraving machines, foam engraving machines, etc. And CNC router can be used to make badges, modeling, steel molds, carved seals, furniture uses of cnc router machine id, gifts, souvenirs, handicrafts, signboards, sign making, prototyping, punching, printing molds, cutting of advertising characters, production of carved advertising light boxes, etc.

Besides that CNC wood router can also be used for engraving various types of two-color plate signs, stone doorplates, three-dimensional notice boards, decorative gifts, light box pieces, two-color human statues, embossed medals, uses of cnc router machine id light houses, organic plate reliefs, three-dimensional uses of cnc router machine id heads, etc.

Woodworking engraving machines are widely used in the furniture industry due to their high processing accuracy, simple operation, strong practicability, easy maintenance, and fast processing speed. The application of woodworking engraving machines in the furniture industry is mainly reflected in the functions of carving, embossing, cutting, hollowing out, which greatly exerts the artistic creativity of the furniture industry and can perfectly combine furniture design and furniture manufacturing.

And common applications of the engraving machine in the furniture industry include processing of wave boards, cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft windows, etc.

CNC router machine in the mold industry mainly reflects the engraving of various wood and foam.

|

Ridgid Table Saw Router Insert 64 Toolkraft Radial Arm Saw Version |

Emily

28.04.2021 at 18:11:55

SeNaToR

28.04.2021 at 19:54:53

Buraxma_meni_Gulum

28.04.2021 at 21:15:36

SUPER_PUPER

28.04.2021 at 13:18:42

GULESCI_QAQASH

28.04.2021 at 15:51:51