Rockler T Track Router Bit Yaml,Best Woodworking Ideas Zone,Best Entry Level Wood Router Vehicle,Metal Storage Cabinet Padlock Error - Easy Way

Place to store a bench or two when not in use. Dust collection area for under the table saw. Improved shop lighting when working on projects.

Comfortable floor mats for standing areas around the table and table saw. It took about a three full days to build and finish it. I am so pleased with how it turned out and how useful it has been so far.

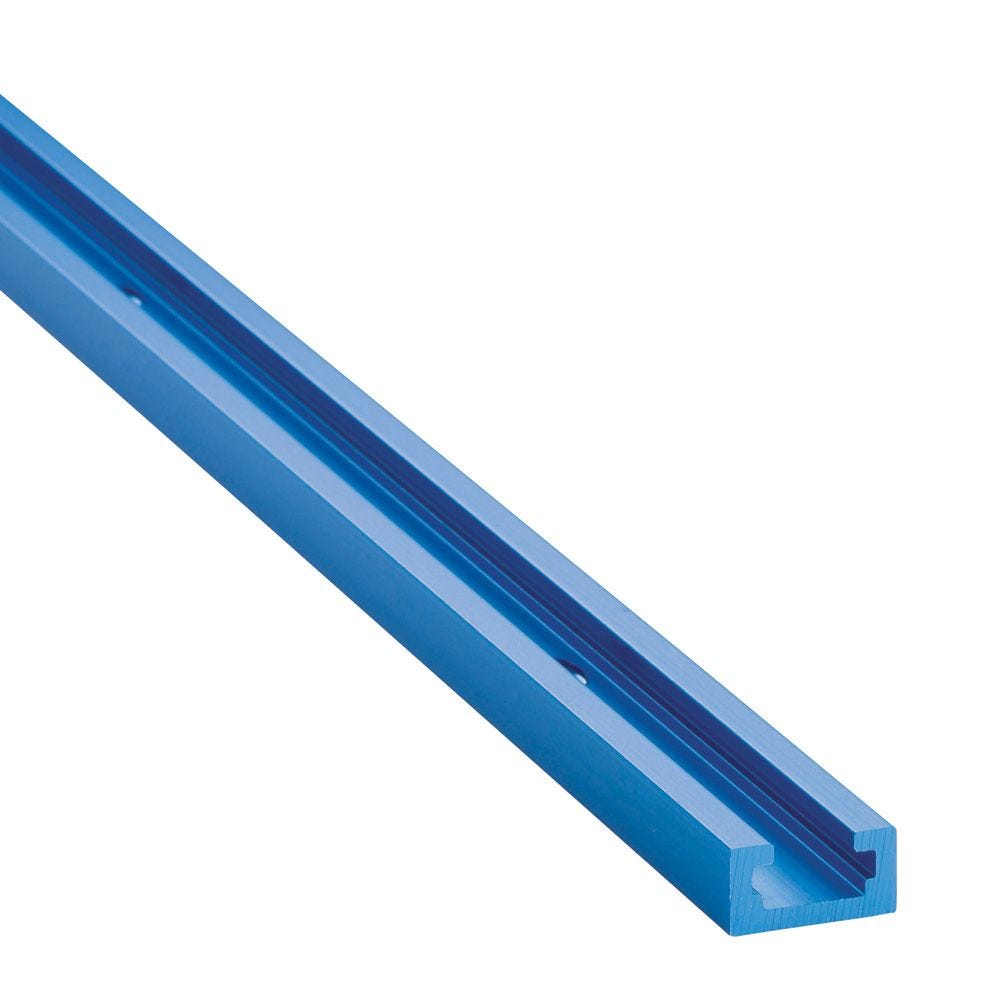

Here are some closeups of the table top features of the table saw workbench. This is the awesome router table that I now have. It features a fence that slides back and forth in the T-Track and is easily removed for an entire table of flat surface to work on. A really big stop switch attached to the router for better safety while routing.

A sweet bench vise. Tons of room for using the T-Track clamping system with all the different ways to clamp projects. Lockable heavy duty casters. Bench storage and see my new Hoosier step stool setup here and comfy floor mats. Why not be comfortable in your work space right? Oh and this cord reel has been amazing to use. It also locks in place if you only need ten feet.

It really cleans up the shop Rockler Tongue And Groove Router Bit Free being able to retract a power cord back up in a nice neat reel. As we said, we love working with Rockler because of their amazing products!

FYI these are affiliate links, which means if you click and purchase through these links, we receive a small commission that helps fun us creating new projects and videos like this — I really love these products, so I highly recommend them! Now I will show you how to make your own. Below you will find the woodworking plans, tools, materials, cut list and steps of how to make your own table saw workbench.

The only thing that might be different in your plans would be the type of table saw that you would use to build it in. Mine was a fifteen-year-old Delta table saw. You could even leave out the table saw and just build the table if you like. There are many options here. Be sure to use cabinet grade plywood or better quality for flatness and select all your wood that is as straight as possible. Keeping the legs square to the outside corners and centering the middle leg assembly to the plywood base.

Predrill the holes to avoid splitting. Attach two swivel casters in the middle. Use four lag bolts per caster and add a lock washer and a washer to each lag bolt.

Flip table over and attach long beam supports between leg assemblies with pocket screws. I was able to clamp a block of wood under the long support to hold it flush with the top of the leg assemblies.

Here is how the supports look finished. Cut out the top corners where the end beams and middle beams are with jig saw. Below I am screwing the partition in to the bottom of the table. You will also be able to screw into the top support beam as well. Attach the second plywood workbench top the the top of the first plywood workbench top with wood screws from underneath.

Be sure the keep screws out of the path of the router channels for the T-Track. At this point the table is all built and ready to use. I am taking it further though to add all the other goodies to it.

Cut out table saw hole with circular saw and jig saw. Measure out the size of your table saw top and cut it to fit that size. Use tape to protect the edge of the plywood. Cut out corners to wrap around the legs. Assemble shelf and supports with screws. Cut out hole for table saw dust to fall into. That way the table saw still has something to sit on. I jacked up the shelf and clamped it in place so I could screw it in underneath. I also squared it off and screwed it in through the partition.

Rout out miter gauge outfeed channel in workbench top. Rout it long enough to get the miter past the blade of the table saw. You want the channels to be deep enough to keep the top of the T-Track flush or just below the surface of the table top. See top view of table for layout of channels. This is where the T-Track intersections will go. Cut out router lift hole with router at the depth of the lift plate. Start routing in the middle and work your way around in circles until you get to the edges.

At the edges I clamped down wood as bumpers to keep my lines nice and square. Sand and polyurethane table top. I sanded with grit sand paper. On the outside edges I used an orbital sander to remove all the print on the boards and level the two top layers together. After I sanded I brushed in four layers of scratch resistant polyurethane. I also sanded with grit sand paper between coats.

I wanted it to be a really nice smooth surface. I started with the intersections then cut the T-Track to length with a metal blade on the jig saw. This part was fun because it was all coming together. Level the table saw with shims. I gave myself some wiggle room to be able to shim it up to the right height of the table top. I got it nice and flush with the top. Install router lift adjustment screws.

I installed four of these adjustable screws around each corner of the router lift for fine tuning the lift to the table. I had to go to the hardware store and pick these up.

Once these are installed, all you need to do with this screw is reach under the table to level out the router lift flush with the top of the table. You should only have to do this once when you first install the lift. Here is a picture of the screws and how they are installed. Drill a hole for the nut and screw it in with Rockler Tongue And Groove Router Bit Translation an Allen wrench.

Then reach under and make the fine tunes adjustments to the level of the lift. This is a longer version of the two screws that came with the lift. I added the nut to a longer screw that matched. The nut gets hammered into the bottom of the table, so it would clamp the lift on really tight.

This is how it ended up. Nice and flush. Sign in for more lists. Feb 08, PST. May not ship to Taiwan - Read item description or contact seller for shipping options. See details. Seller's other items. Related sponsored items. Showing Slide 1 of 2 - Carousel. Similar sponsored items. Built-in Vacuum Port Aluminum.

Seller assumes all responsibility for this listing. Item specifics Condition: Open box: An item in excellent, new condition with no wear. The item may be missing the original packaging or protective wrapping, or may be in the original packaging but not sealed. The item includes original accessories. The item may be a factory second. See the seller's listing for full details and description.

See all condition definitions - opens in a new window or tab Read more about the condition. Used one time only!!! Like new.

|

Woodworking Turning Tools 50 Elmers Carpenters Wood Glue Sds Type Carpentry Shop Nz 80 |

Avarec_80

02.08.2020 at 22:56:28

BESTGIRL

02.08.2020 at 10:37:10

RAMIL

02.08.2020 at 13:34:16

TM_087

02.08.2020 at 11:32:47