Best-cnc-carving-software-reset,mini-hand-planer-harbor-freight-quarter,toilet-flush-button-spare-parts - Try Out

Set the Work Speed , i. Set the Plunge Speed. This section explains the steps of generating G-code in Relief mode and the meaning of each parameter. This is an example of wood carving in which a relief will be made. The size of the wooded board used here is 40 x 60mm. When you set the size at 40 x 60mm in the software, the image size to the input size ratio is shown as follow.

The target depth we set in this case is 3mm P. The board is 20mm thick. The step down here is 0. In this case, we set it at 3mm. Set the Density. Higher density means more carving times. To achieve the optimal carving effect, the software may recalculate the density when generating G-code. You can invert the shades of color on the image, which means the primary light-colored parts will be dark-colored.

The darker the color is, the more it will be carved. If the machine is not yet connected to Wi-Fi, please select Settings in the main menu, tap Wi-Fi and connect to your network. Before you connect your computer to the machine, make sure both the computer and the machine have connected to the same Wi-Fi. Note : Unlike setting work origin on touchscreen, you will need to set work origin in the software.

When everything is ready, click to start carving. Note 1 : The computer must be connected to the machine via Wi-Fi throughout the process. Note 2 : You can change the settings for Work Speed during the carving process. Note : The computer must be connected to the machine throughout the process. If the machine is not connected to Wi-Fi network, please tap Settings at the main interface, enter the Wi-Fi page and link it to your Wi-Fi.

Click Send via Wi-Fi in the Workspace. When the G-code file is received, tap Yes on the touchscreen to enter the preview page. Attach the clamp set to the CNC carving platform, then fix the material by screwing the wing nuts. Screw the entire unit onto the shank as tight as possible, then completely tighten the ER11 nut using the open-end wrenches. Find out where the carving will be by setting the work origin. The work origin corresponds to the 0, 0 coordinate origin in the software.

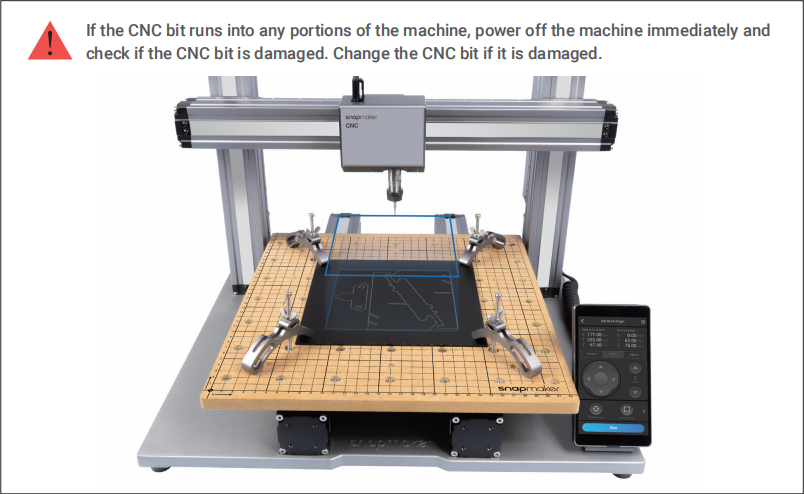

After receiving the G-code file, tap Yes and Next on the touchscreen to enter the screen of setting the work origin. Now the CNC bit should be about 5 mm away from the material. Place the calibration card or a piece of A4 paper between the CNC bit and the material. Tap Set Work Origin. If part of the boundary runs beyond the material or the CNC bit runs into any portions of the machine, reset the work origin and run boundary again.

Clean the finished work and the machine using a dust collector, then remove the finished work using the Diagonal Pliers. If you change the provided M4 x 70 screws to M4 x 90 screws, the fixtures can fix materials with thicknesses of up to 50mm.

When the material thicknesses are below 6mm, you can change the provided M4 x 70 screws to M4 x 50 screws. It helps prevent the CNC module from colliding with the fixtures. You can use the second fixture position to fix most materials. For big materials of which their edges nearly reach the edges of the CNC carving platform, you can use the third fixture position to fix those materials.

It indicates that the center of the SVG file corresponds to the 0, 0 coordinate origin in the software. In that case, it is recommended to set the center of the material as the work origin to ensure the machining region is inside of the material. If so, the machine will start operation at the center of the material. Note : In the software Snapmaker Luban, the work origin can only be set on the surface of the material.

Do not set the work origin below the surface of the material. If you want to set the bottom left corner of the material as the work origin, you can move the SVG file to the top right corner in the software. In that case, the machine will start operation at the bottom left corner of the material. When you use Flat End Mill in Vector mode, it is recommended to use the parameters below. Snapmaker Snapmaker 2. Note 3 : Three modes are available in the software, including: Relief : You need to upload greyscale images, and the layering effect is based on the different shades of color on your original images.

Select Vector mode to upload an SVG file. You can rotate, move or flip the image as needed. Tab Width : The width in this case is set at 2mm, as shown in the figure below. Select Relief mode to upload an image. Connect the machine and the computer with the provided USB cable. Insert the USB disk into the controller. Place the material on the center of the CNC carving platform. OnShape software system is available and delivered over the Internet via a Service model. It uses cloud computing extensively.

Each upgrade of this software is released directly to the web interface. It allows the users to collaborate on a single shared design.

It is a building information modeling software that supports a finite element method. This software can use Python programming language. This is mainly intended for mechanical engineering use. TinkerCAD is an online 3D modeling program that runs in a web browser. This has a simple interface and ease of use. This is a popular software for creating models for 3D printing and constructive solid geometry. These free CAD software are much simpler and easier to use. It not only provides 2D drawing but also helps to create 3D models.

If you do not want to create a design by yourself, you can try ready to cut DXF designs as an alternate option. These are easily available in the market. The Scan2CAD has more to add compared to other options on the list. It can give you ready-made CNC designs. It is a platform where people from all walks of designing like woodworkers, architects and professional designers can work together and download a ton of different CAD files.

This is the language used in CNC machining. This software uses the models and assemblies created in CAD software to generate toolpaths that drive machine tools to turn designs into physical parts. It can eradicate the gap between design and manufacturing by the appropriate realization of drawings, designs, and models and provide the anticipated output. Eventually, this expands the scope of production and manufacturing.

G-Code is one of the most popular and widely used programming languages. A G-Code is used to instruct and control automated tools. This also provides the direction in which the machine should move. It directs the machine on the speed and depth of the movement. There are many types of G -Code files, the most popular G-code file types are.

NC and. For simple requirements such as circles and lines, you can easily create G-Code manually. But it is even easier to produce the same with the help of CAM software.

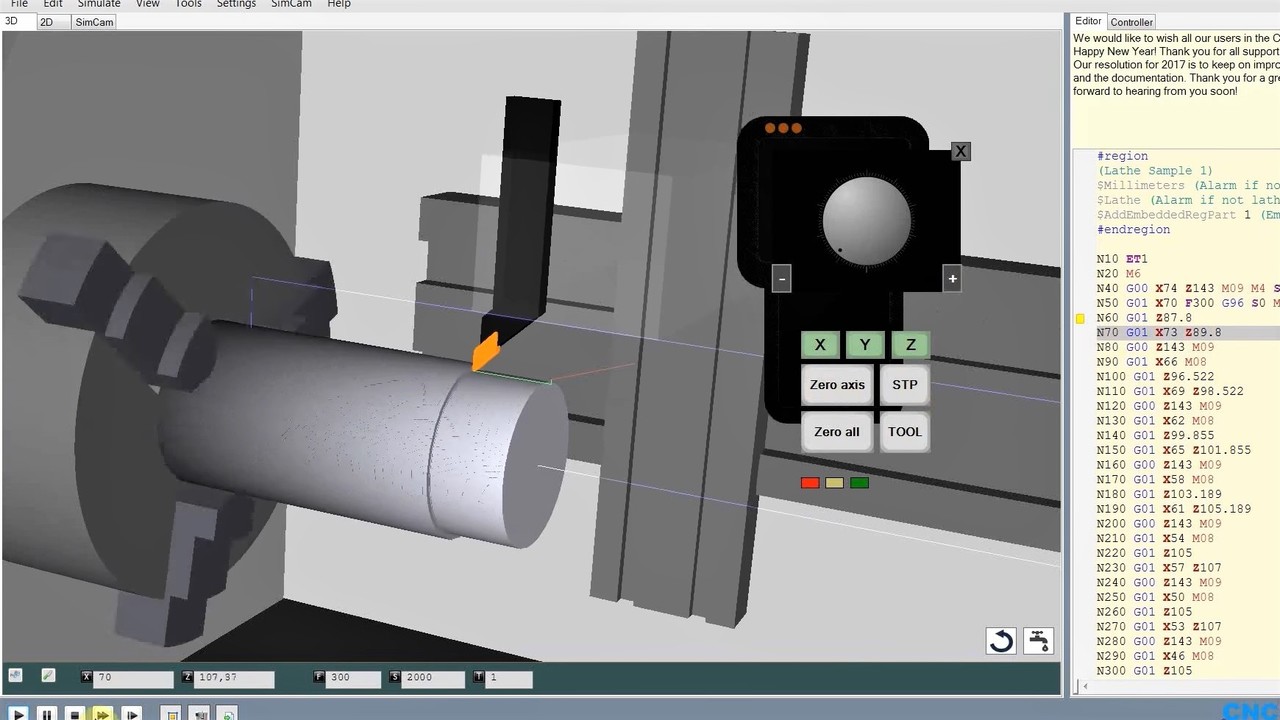

In the latest CNC Machining system, the 2D drawings are no longer required for manufactures a machine. The current machining systems can directly interpret the part geometry from 3D CAD files. This is the fastest software to generate code. It is capable to process up to 5 axis machining. FreeMILL is a milling module for mills and routers. It allows full simulation of the part models. There is no time limit, code limit or trial limit for this software. It helps to create toolpaths.

G-Simple is a simple CAN package is for 3-axis machining. It applies various filters for managing library tools, removes excess materials, drill adjustments and text engraving. PyCAM generates toolpath for 3 axis machining. This supports many toolpath strategies for 3D and 2D models.

It runs on Linux. Scan2CAD converts raster designs to vector file format in a few seconds. The raster and vector editing suites can be used to create the optimal vector image for any CNC design. It supports 33 file types and comes with batch processing. There are two types of CNC control software. One control software built into your machine and other is PC-based software. If you are using a CNC machine such as HAAS Vertical Machining, you would require a complete solution complete hardware and software solution that is built into the machine.

In this, you can transfer G-code directly to the machine. The Mach series works on most Windows PCs. The latest version is Mach4. This is customizable. This can control up to 6 axes of a Machine. This software is very inherent and customizable. Mach3 is one of the most well known and widely used CNC machine controllers. LinuxCNC is completely open-source.

This software runs on Linux. This can control up to 9 axis. This supports rigid tapping and cutter compensation. This helps in numerical control of machines. TurboCNC can control up to 8 axes of motion, and it provides fully parametric programming. This is fully functional shareware. Universal Gcode Sender is widely used software used to convert arcs to line segments. This has configurable G-Code optimization, duration estimates, support cross-platform, 3D G-Code visualizer and many more to add.

Caliper2PC is a digital readout for milling machines, lathes, and other tooling machines. This is a very adaptable and user- friendly software. CNCZeus is the advanced low-cost machine control software.

Perfect for large professional machines. Its features include cutter composition, digitizing probe, optimized assembly language and more. Woodworking is the most widely used application of a CNC router since it offers a lot of benefits and flexibility when working with wood than with any other material.

For such users, we have reviewed the best woodworking software since there are a lot of things to consider when getting your first woodworking design software that will allow the functioning of tools and elements that you want. Both G-code and M-code carry different information.

A G-Code Geometry is related to the placement of the hardware relative to the workpiece like cutting tasks and determining units. A CNC machining is not hard to learn. But once you get the hook of it, everything will be easy with time. By using a CNC machine software, you can take complete control of all the processes involved in the manufacturing and monitor end to end process.

The production process of a CNC router reduces the number of steps required to make a part. The entire fabrication process is automated and by choosing the right CNC software at each step, you improve the efficiency.

The same components can be reproduced and replicated as many times as required without compromising the quality. A single person can supervise multiple CNC routers with ease if he gets accustomed with the cnc software. There is no need to make a prototype model. You can directly simulate the requirements in the software. There are a few limitations associated with CNC. Based on the age and sophistication, CNC machines have limited capabilities in control and drive systems.

Most CNC control softwares only interpret straight line movements and circular arcs. In many cases, the arcs are restricted to the principal XYZ planes. The demand for the CNC router with immense capabilities is still on the rise.

Though it has many limitations, its advantages outnumber them. Hence, CNC is here to stay long and enhance its capabilities now and then. I am a beginner with a style cnc router I am doing memorial stones and would like to know what is the best software out there for a beginner? Thank you. The software has been discontinued by Autodesk since , however some of our users were still able to download and use it from opensource resource.

But we will now add a line next to it with some of the alternatives to ArtCam. Let me know if you have any recommendations for us. Hello — I am in the process of purchasing a CNC router that engraves on stone and the images are quite large.

The apparatus is special as it is the framework without a platform and it is placed on a railing system that lies over the stone and engraves. Because the images are quite large, sometimes larger than the apparatus, I am looking for a software that allows you to pick up the apparatus and move it while keeping place of where the image has stopped and will start up again to finish the engraving.

Can you recommend a software that will accomplish that? You can use Autodesk since that has better usability and ease of making complex patterns in an easy way.

Hello Thank you for this wonderful article! I am in the market to buy CNC machine to produce custom furniture with lots of carvings and engrave in the wood including custom design for the fabric , if you were me what machine would you buy and which softwares would have been your choice for CAM and CAD? Regards Anna. Thanks for dropping by, Sure so if I was looking for a CNC machine that can make custom furniture which means there will be a lots of operations that will involve wood as a material.

Hey great article thank you for the excellent information.. I have a a I have upgraded the spindle mount and spindle from to I lost the CD for grbl for it. Would you suggest I use Pycam as my cam sorfware. Or could I use easel? Any advice would be very appreciated. Thank you Tamati.

|

Turned-table-legs-home-depot-australia Log-futon-plans-journal Carving-kitchen-washington-dc-04 |

Sevimli_oglan

29.05.2021 at 13:54:52

FENERBAHCE

29.05.2021 at 14:16:39