Wood Planer Tips And Tricks,Simple Carpentry Projects Us,Japanese Hand Saw Types Journal,Open Hardware Monitor Zabbix Queue - Easy Way

But there is so much more that can be done with a planer with various tips and tricks. It can end up being a really versatile tool if you know how to use it right. Read on to learn more about all you can do with just a thickness planer! Here is some useful and simple thickness planer tips and tricks to get the most out of your thickness planer!

It is often considered necessary to have at least one smooth side while passing a piece of wood under the planer. If at least one side of the wood is not smooth, it might rock to and fro under the rollers of the planer.

But there is a simple trick for your planer to work with an unevenly surfaced wood plank, and that is for the sleds and shims. The wood will then ride on the sled, and the shims eliminate the rocking which provides a smooth piece of lumber. Attaching the sled and workpiece to the hot melt glue will secure the shim from shifting. Then take off the sled and plane the other side.

But the way to achieve this is very easy! The auxiliary bed carries the wood piece when it goes through the planer, placing it at a level high enough to hit it with the roller and planer knives.

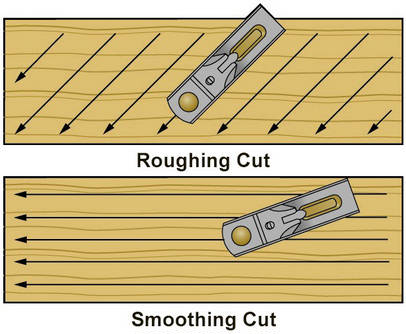

Take very shallow cuts until you achieve the thickness level you wanted. Video Credit — Tayler Made. It is possible to also plane edges of multiple pieces to get the required width.

For this tip to work, you just need to put the pieces in a group and run the whole set all at the very same time. You should consider cutting every piece to a similar average width before planning for the best results. This is one of the crucial thickness planer tips and tricks. However, there is a simple tip for planers to do that as Woodworking Square Tips And Trust well! You simply need to make a board of wood seem longer than it actually is.

A little TLC will help your planer be a reliable workhorse in your shop for many years. Check the planer table for flatness with a long straightedge. Assess the length and width of the table as well as diagonally. If your table has any warped or low spots—which are rare—contact the manufacturer for assistance. Clean the planer table with mineral spirits; then apply a coat of paste wax so boards will glide across smoothly as the feed rollers pull them.

Buff the wax with a soft cloth. Use dust-collection equipment when possible, and use compressed air to blow away debris from the cutterhead, rollers, and table surface with each use. This helps avoid feed rollers that slip, and dimpled wood surfaces that result from feed rollers compressing chips against the workpiece. When the feed rollers lose grip, a workpiece can stall inside the planer and become gouged or burned. If you see debris build up, wipe the rubber feed rollers with mineral spirits or naphtha using a clean rag to ensure a good grip.

Check the motor brushes every hours for wear on the carbon faces. Excessive motor load, caused by taking deep cuts in wide stock, could hasten wear. Clean the head elevation screws and guide posts by blowing away dust and chips with compressed air. Use a brass-bristle brush if needed. Then lubricate the posts and threads with dry paraffin wax for smoother movement.

Clean dust and pitch from the knives using mineral spirits and a clean rag or brass-bristle brush. You'll most likely need to do this after planing wood with high sap, tar, or oil content, such as pine or teak. Be careful not to cut your fingers on the knife edges. When knives dull, they often tear the wood or pull chunks from the surface, so replace or sharpen them at the first sign of dulling.

Don't bother sharpening double-edged, disposable planer knives; it proves too difficult to get a consistently sharp and straight edge on all knives—which must match perfectly. Keep a spare set of knives on hand to minimize downtime. Clean the drive chain and sprockets only if they become covered in dust or chips. Use a brass-bristle brush and compressed air. Avoid removing grease or lubricant from any exposed gears.

Wood dust messes up a shop quickly and can lead to respiratory problems. Tablesaws with enclosed Skip to main content. Previous X of 11 View all Next. Tip 1 Check the planer table for flatness with a long straightedge. Tip 3 Clean the planer table with mineral spirits; then apply a coat of paste wax so boards will glide across smoothly as the feed rollers pull them.

|

Modern Woodworking Textbook Answers Chapter 1 Map Deck Groove Router Bit Antique Wooden Carpenter Tool Box Wall |

QAQASH_004

20.07.2021 at 16:38:27

Diana_84

20.07.2021 at 20:29:31

Birol

20.07.2021 at 16:54:25