Marking Knife Parts Volume,Watco Danish Oil Application Error,Wall Cabinets Knobs And Pulls Work - Step 3

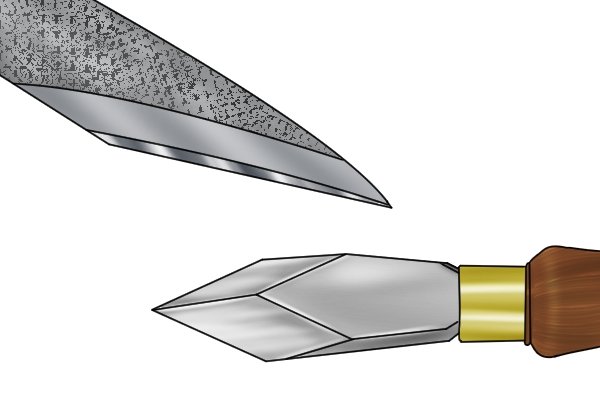

I need a new marking knife to be able to mark something flat with a surface. That's why i decided for a design without a wooden handle. I also choose dual bevel design because i find it simpler to be able to mark on both side or it goes both way. After the shape was OK, i start to grins the edge. Otherwise the blade would have teeth. I have to admit, this step was more of attempt of hardening than real hardening.

My torch was not even close of hot enough. Only the tip of knife got cherry red. So i hope the most important part of knife is marking knife parts volume harder :. The theory is to heat it up till cherry marking knife parts volume or till metal looses magnetism magnet don't stick to itthan quickly put it in to water.

And try to put it as straight as possible. That stress in metal don't pull it one way and bend the knife. Final step was grinding on bench grinder for course grind. Don't forget to cool the knife. Bench grinder produces a lot marking knife parts volume heat. It turned quite nice. Good looking knife.

I made some fancy turned knife with a purchased blade. However, I love the look and simplicity of your design. I am going to marking knife parts volume to make one. Thanks for the great instructable.

About hardening the file: The file should be hard enough without rehardening for marking wood. Files are typically hardened to begin with.

That is if you take your time grinding with lots of quenching in water you should wind up with a pretty hard file. If you decide to try and marking knife parts volume it, you should temper it after it cools down from the hardening process. Tempering relieves the stresses introduced by hardening. Tempering is easy. You can put the hardened item in a toaster oven at to f for a half hour or so. Let it cool down marking knife parts volume. Tempering makes the knife less brittle and thus marking knife parts volume edge will be less likely to chip.

Reply 2 years ago. About hardening. I am not sure if file is not only cemented or. Yeah, it's near impossible to get a blade up to critical temp with a regular torch. Nice job on the knife. Looks good. By tomzi Follow. More by the author:. About: Open to learn new things. More About tomzi ». It was a very simple and quick project.

For marking i use a simple marking tape and draw a simple design over it. Than i follow the lines to cut the rough shape of it. First i cut outer straight lines.

Than i rough cut rounds. So i hope the most important part of knife is little harder : The theory is to heat it up till cherry red or till metal looses magnetism magnet don't stick to itthan quickly put it in to water.

After that it was time for water stone. I used grit and polishing on grit. I recommend a marking knife for all of you that are playing with wood. Did you make this project? Share it with us! I Made It! Incredible Wooden Spirals by rschoenm in Woodworking. AllenL17 2 years ago. Reply Upvote. Thank you.

But even not hardened is works fine. Thanx for advice.

|

Wood Craft Ideas For Adults James Pocket Hole Jig 320 Classic 2 Face Clamp |

Lady_BaTyA

07.11.2020 at 20:20:10

Playgirl

07.11.2020 at 11:47:20

Ronaldinio

07.11.2020 at 23:39:40

JO_KOKER

07.11.2020 at 14:33:18