Cnc Table Clamps Number,Elmers Carpenters Wood Glue Sds Ipad,Digital Picture Frame Tool,Marking Knife Diagram Kitchen - And More

To find out more about these uses for Workholding, check out our excellent series on 4th Axis Basics. A pair of milling vises sit side by side on a machine table…. Plates, Plate Fixtures, and Clamps. As useful as vises are, they have a sweet spot for part size. They have a difficult time with really large plate work, though as mentioned you can move the jaws to the outside positions for medium-sized plates.

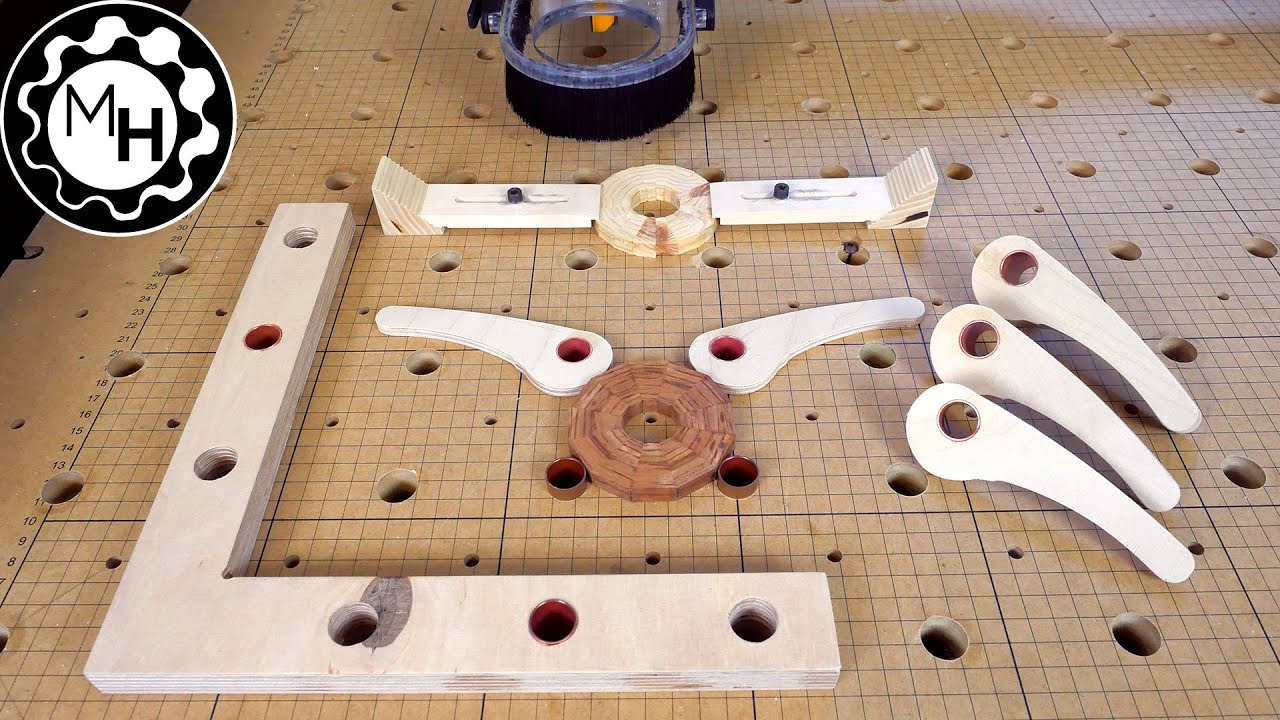

And, they can also be less than optimal for very small parts. Sure, you can fit multiple parts in a set of Soft Jaws, but the space between adjacent vises and the space required for the vise mechanism makes it hard to fully fill the table with as many small parts as you might otherwise be able to. This one uses Mitee Bite Pit Bull clamps. The effect is not unlike tiny milling vises designed to fit each part just right. The most common type of clamps are called step clamps because they have little steps machined on them.

Here are some typical Step Clamps:. Step Clamp holding down plate, step block supporting end of clamp, and bolt goes through T-Slot Nut….

Pictured is a typical Step Clamp Set. By stacking the Step Blocks and using longer bolts, you can clamp workpieces that are quite tall. When using step clamps, keep the bolt close to the workpiece rather than the step block. Also, it can be helpful to angle the clamp down on the part by raising it up a step or two from level. You may also want to put a shim of soft material between the clamp and the workpiece if you want to avoid marring the workpiece.

Soda can makes a great shim for this purpose if you slice out some strips with your snips. Step Clamps grip the top of the workpiece, which is sometimes inconvenient because you might need to machine the area being gripped.

Toe Clamps grip the side of the workpiece to give you full access to the top of the workpiece. There are a wide variety of different styles available:. This toe clamp moves the clamp down a ramp when tightened to press against the workpiece…. These Mitee Bite Edge Clamps have an eccentric bolt head that forces the hex against the workpiece as you tighten it…. Turns out some CAM software can help out with workholding quite a lot by automatically creating tabs.

Using MeshCAM to add tab supports so you can machine a part on 2 sides…. The Glue needs to be something that will release when needed. For example, Super Glue releases at a particular temperature just like LocTite.

The fumes from it are toxic, so take care to release with plenty of ventilation. Double sided tape can work great, especially for really thin materials. Wax and Low Melting Point Alloys typically Bismuth alloys can be used to embed the workpiece and create grippable area.

When the machining is done, one can melt the wax or alloy away and save for reuse. Need to apply uniform pressure to hold a part down? Maybe a vacuum fixture is the answer. Sea level air pressure is A vacuum fixture pumps a vacuum under the part so that air is pressing down on every square inch of the top with That can create considerable holding force if there is enough surface area regardless of the shape of the top or how thin the material may be.

Perhaps the biggest disadvantage of vacuum fixtures is their hold-down force is limited by surface area—that means small parts can pop off relatively easily. When cutting forces exceed the hold-down force a vacuum table can pull, the part pops off and is generally ruined.

Until now, fixing the problem has been hit or miss, but our G-Wizard Calculator software now has the ability to limit cutting forces to what your vacuum table can handle. For more information, check out our article on this special feature. While we typically think of machining round parts on lathes, there are many times when you may need to mill them as well.

Just bolt or clamp them down to your mill table. For example, use a 3 jaw chuck or a bank of collet chucks. Amazon Music Stream millions of songs. Amazon Advertising Find, attract, and engage customers. Amazon Drive Cloud storage from Amazon. Alexa Actionable Analytics for the Web.

Sell on Amazon Start a Selling Account. AmazonGlobal Ship Orders Internationally. ComiXology Thousands of Digital Comics. DPReview Digital Photography. East Dane Designer Men's Fashion. Shopbop Designer Fashion Brands. Deals and Shenanigans. Ring Smart Home Security Systems. Blink Smart Security for Every Home. Amazon Subscription Boxes Top subscription boxes — right to your door. PillPack Pharmacy Simplified.

Only 1 left in stock - order soon. Get it as soon as Mon, Mar Related searches. Need help? Visit the help section or contact us.

Go back to filtering menu. Skip to main search results. Eligible for Free Shipping. Customer Review. From Our Brands. Packaging Option. New Arrivals. International Shipping. Amazon Global Store.

|

Do It Yourself Wood Gate Years Ryobi Woodworking Tool Set Queue Freud Raised Panel Bit With Backcutter |

warlock

29.07.2020 at 10:50:54

KAMRAN_17

29.07.2020 at 16:21:59

KLIOkVA

29.07.2020 at 19:46:28