Woodworking Dust Collection System Template,Woodworking Plans Patio Furniture Value,Best Woodworking Bench Keyboards - Step 3

Debris, metal or otherwise, not only makes a racket when it hits an impeller but also imparts stress on the bearing and will shorten its life.

One way to reduce the risk of fire is to choose a single-stage collector with a plastic or aluminum impeller. Steel impellers are fine, however, if you avoid using the dust collector to sweep up miscellaneous debris off the floor or workbench.

I also used the 1-hp collector with a PVC duct system 4-in. At that distance, because of increased resistance, the air volume drops to under cfm, less than recommended for woodworking tools. In reality, however, one can live with that. When I hooked up the 1-hp collector to a newly installed metal duct system, with my tools in the same configuration as before, I was really surprised.

The air volume was back up to cfm, very acceptable. Then I hooked up my old 1-hp collector, which is outfitted with oversized felt bags available Commercial Woodworking Dust Collection Systems Zip from Oneida Air Systems that improve airflow and capture fine dust , and I measured almost cfm.

Hooked up to a 6-ft. Cyclones and two-stage collectors have slightly more internal air resistance; hence the lower cfm reading. Performance ranged from good to so-so, depending on how much sawdust was being spit out by my tools. The best way to direct maximum airflow to the tool being used is to attach a blast gate to each hose.

Hooked up to a PVC duct system a run of about 25 ft. A two-stage unit such as the Oneida costs almost twice as much. Penn State Industries also sells a cyclone collector. With two blast gates open, the air volume dropped and was insufficient to operate two big machines at once. More horsepower does mean more noise; both registered 85 decibels at 8 ft. The Delta comes wired for volts but can be switched over to volts.

The Oneida comes without cable or switch. It can be wired to run on either current. A 2-hp unit can sometimes handle two machines at once Hooked up to two 6-ft. When I connected the 2-hp units to the PVC duct system, they too were robbed of considerable power, but one machine could be operated at a time with satisfactory results.

When connected to a metal duct system, the Jet collector really moved a lot of air, cfm at the tablesaw-jointer connection after about 25 ft. With two blast gates open, the air volume was reduced to less than cfm, still acceptable for some operations. The Dust Boy produced slightly lower readings but still had more than enough power to run one tool at a time in any configuration.

If you regularly operate more than one machine simultaneously, it would be wise to look at 3-hp or bigger dust collectors. They cost more, however.

Most 2-hp collectors come wired for volts. The Dust Boy can be run at either volts or volts. On the matter of choosing a dust collector, a two-stage cyclone gets my top vote. A small cyclone collector takes up less room, is easy to empty and runs very clean. For example, on all of the single-stage units, even after running them for only an hour, fine dust appeared on the machine and in the area around it. The Oneida cyclone, outfitted with an internal filter, rubber gaskets and wide metal ring clamps, seals better.

Two-stage units such as the Dust Boy Delta also makes a two-stage collector are also nice Portable Woodworking Dust Collection Systems Free and compact. The Dust Boy takes up 6 sq. The Dust Boy as does the Oneida comes with a Leeson motor and cast-aluminum housing and impeller fan , and the sturdy plastic barrel holds a lot of debris, 55 gal. Before it can be emptied, however, the heavy motor and housing must be lifted off.

Removing the lower bag of a single-stage collector is an easy matter of loosening a band clamp. The real fun begins when you try to reattach it. The lower bag must be wrapped around the metal waist of the machine and held in place before the clamp can be cinched. Some manufacturers, such as Jet, add an elastic band inside the lower bag to facilitate reattachment somewhat.

The skirt and a standard gal. I just wish the skirt were made of felt rather than the more porous woven fabric. This setup will reduce the air volume. When an ad says a collector is rated at 1, cfm, what does it mean?

Not much, really. Choosing, using, and maintaining a dust collection system in your woodworking shop is critical for shop safety. Find out all the tips and techniques to tame sawdust in your woodworking shop. With an old handscrew clamp and some scraps of hardwood, you can set up your thickness planer to Skip to main content.

Dust Collection. How to buy a dust collector. Choosing a dust collector can be anything but simple. We've stripped away the mumbo-jumbo to show you what you really need to know.

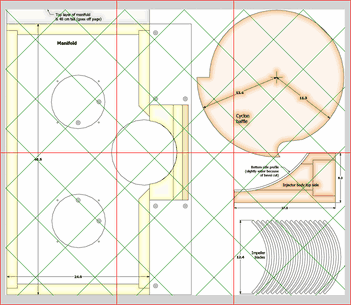

Just browse this collection of 15 DIY dust collector ideas that are impressive, cost-efficient, power-saving and will not be too loud to cause pain in your ears. Time to make it super easy to clean space by quick dust extraction and separation. These DIY dust collector plans will provide step-by-step instructions, diagrams, and even video tutorials to build one stage or two-stage cyclone dust collection like a pro.

Get the best out of your plastic buckets by making a dust collector, use 1 or 2 buckets to build a dust collector, will just work fine. You will get a whole bag of tricks too about how to upgrade a dust collector so it will work fine for the current situations.

These DIY cyclone dust collector projects will provide all the tips to build a lovely one in no time. Make it super quick and easy to clean your home with this wall mount dust collector.

Next, you need custom filters, expandable dust hose, and miter saw dust collector, etc. Get here free plans to build a custom DIY cyclone dust collector, will surely impress with its super functional behavior. Make the dust collector using plywood, a trash can, and custom pipe fittings.

Next, add it up with a normal shop vacuum to make this see-through cyclone dust collector. Get here a free plan to build a quick DIY cyclone dust collector system, will give a big helping Woodworking Dust Collection System Journal hand in home cleaning. Build this cyclone dust collector using a shop vacs, and this will not let the filters clogged but will keep them running smoothly. Time to save a lot of home cleaning time using this system. If you are having dust allergy, then time to keep your lungs safe from the airborne dust using this cyclone chip separator will help keep your home clean and tidy.

This system uses a 2HP model from the Harbor Freight and uses the plastic drums as trash cans. Details here instructables. Save a lot of home or shop cleaning time with this dust extraction, made for home workshops. It is super quick to compose, and the whole system will cost you much less. Grab the rigid 4-gallon shop vac and a mini DIY cyclone dust collector to build this dust extraction system.

|

Martin Woodworking Machinery Uk 8th Carpenter Bees Wood Holes 4k Furniture Drawer Parts 04 Fine Woodworking Kitchen Cabinets To |

SPAWN

15.09.2020 at 15:36:15

Inga

15.09.2020 at 18:27:51

Play_Girl

15.09.2020 at 12:52:35

Akulka

15.09.2020 at 19:42:48