Wood Turning Wood Types Zip,Timber Products Company Corinth Ms 38834,Best Raspberry Pi Desktop Names - Plans On 2021

Tuning is the craft of using turrning wood lathe wood turning wood types zip hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheelthe wood lathe is woov simple mechanism which can generate a variety wood turning wood types zip forms.

The operator is known as a turner, and the skills wood turning wood types zip to use the tools were traditionally known as turnery. In pre-industrial England, these skills were sufficiently difficult to be known wood turning wood types zip 'the misterie' of the turners guild.

The skills to use the tools by hand, without a fixed point of contact with the wood, distinguish woodturning and the wood lathe from the machinists aood, or metal-working lathe. Items made wlod the lathe include eood handles, candlesticks, egg cups, knobs, lamps, rolling pins, cylindrical boxes, Christmas ornaments, bodkins, knitting needles, needle cases, thimbles, pens, chessmen, spinning tops; legs, spindles and pegs for furniture; balusters and newel posts for architecture; baseball bats, hollow forms such as woodwind typew instruments, urns, sculptures; bowls, platters, and chair seats.

Industrial production has replaced many of these products from the traditional turning shop. However, the wood lathe is still used for decentralized production of limited or custom turnings. A skilled turner can produce a wide variety of objects with five or six simple tools. The tools can be reshaped easily for the task at hand. In many parts of the world, the lathe has been a portable tool that goes to the source of the wood turning wood types zip, or adapts to temporary workspaces.

Woodturning appeals to people who like to work with their hands, find pleasure in problem-solving, or enjoy the tactile and visual qualities of wood. Wood lathes work with either reciprocating or continuous revolution. The reciprocating lathe is powered by a bow or a spring, rotating the wood first in one turnign, and then in the other.

The turner cuts on just one side of the rotation, as with the wood turning wood types zip lathe. The reciprocating lathe may be human-powered with a bow, as well as with spring mechanisms. The reciprocating lathe, while primitive technology requiring considerable dexterity to operate, is capable of excellent results in skilled hands.

For example, reciprocating bow lathes are wpod used to turn aood for the Arabian lattice windows Finding Wood For Turning Zip called Meshrebeeyeh that so charmed Holtzapffel in the s. Continuous revolution of the workpiece can be human-powered with a treadle wheel, or achieved with water, steam, or electric power. The style of cutting does woo have the pause required by the reciprocating lathe's rotation.

Even with continuous revolution, however, the turner controls the contact of tool and wood entirely by hand. The cutters are not fixed, nor advanced automatically, as with the metal-working lathe. The nature of wood defines woodturning techniques. The orientation of the wood grain, relative to the axis of the lathe, affects the tools and techniques used by the woodturner. In spindle turning, the grain runs lengthwise along the lathe bed, as if a log were mounted in the lathe.

Grain is thus always perpendicular to the direction of rotation under the tool. In bowl turning, the grain runs at right angles to the axis, as if a plank were mounted across the chuck. When a bowl blank rotates, the angle that the grain makes with the cutting tool continually changes between the easy cuts to two places per rotation where the tool is cutting across the wiod and even upwards across it.

This varying grain angle limits some of the tools that may be used and requires additional skill from the turner. Moisture content affects both the ease of cutting wood and the final shape of the work when it dries. Wetter wood cuts easily with a continuous ribbon of shavings that are relatively dust-free.

However, the wet wood moves as it dries. These variable changes may add the illusion of an oval bowl, or draw attention to features of the wood. Dry wood is necessary for turnings that require precision, as in the fit of a lid to a box, or in wokd where pieces are glued together.

The character of the wood creates other challenges for the woodturner. Turners of hardwoods and ivory select different tools than Types Of Wood For Turning Quotes those used for cutting softwoods.

Voids in the wood require higher typse speeds, fillers, or extra safety zio. Although other woodworkers value tight, straight grain, woodturners often search wood turning wood types zip the unusual wood from roots, defects, or diseased portions of trees.

The craft of woodturning is preserved and advanced by a community of practitioners. Until the s, an apprentice system in the U. Wood turning wood types zip andindustrial arts teachers, hobbyists, artists, collectors, and tool suppliers developed the symposium format for exchange of information about the craft.

The community organizes regional, national, and international symposiums, publishes journals, and wood turning wood types zip travelling experts at club events. The archaeological record of woodturning is limited to illustrations because wood typss a fiber prone woof rot. Egyptian monuments illustrate a strap used by a helper to rotate the lathe while another worker cut the wood.

Early bow woood and strap lathes were developed and used in Egypt and Rome. Bow lathes continue in use right up to the present day, and much of our Wood Turning Chuck Types Error information about them comes from watching turners use them.

Our knowledge of these humble vessels comes from bowls excavated from shipwrecks, such as the Wood turning wood types zip Rose and the Oseberg burial ship, or dug out of deep wells, where they were preserved in a nonaerobic environment.

Much of this ware was turned from green wood on a spring pole lathe. As early astjpes separate fly wheel powered a lathe via a drive belt. This was a continuous revolution lathe, which led to adaptation to external power sources such as water, steam, and electricity.

This lathe evolved into the 'queen of machine tools' which made it possible to turn parts for other machinery. These lathes worked from geared patterns to cut designs in hardwoods such as ebony. They were favored wopd a hobby by European princes, meriting a mention by Tolstoy in War wood turning wood types zip Peace Woodturners in London organized into a guild as early as wood turning wood types zip Wood Street.

Bythe Turners Company was assigned responsibility for regulating weights and measures by the Mayor. The Company governed the apprentice system, and established turniing for goods.

Inthey were incorporated as the Worshipful Company of Turners of London. Itinerant turners known as Bodgers set up temporary pole lathes near the wood turning wood types zip of wood for turning furniture parts.

In the 19th and early 20th century, woodturners in England worked tpes Turning Shops, [13] usually within the master-apprentice system. In Germany wood turning wood types zip Russia, woodturning was concentrated in villages which had a specialty, such as turning toys. Bow lathes and pole lathes continued in use for decentralized, one-man production of architectural elements and bowls in many parts of the world.

In the US, woodturning was part of wood turning wood types zip curriculum of industrial arts taught in public schools—often a prerequisite for classes in building furniture.

The 'problems' from textbooks included both tool management skills, and tuning to turn objects such as gavels, darning eggs, boxes, wood turning wood types zip, candlesticks, lamps, and legs for furniture. Woodturning skills were used by patternmakers in the making of prototypes and shapes for casting molds used in foundries during the 19th and 20th century. They worked very slowly to achieve precision, using enormous patternmaker lathes and slow-cutting scraping tools.

Woodturning has always had a strong hobbyist presence. In the s, an explosion of interest in hobby woodturning in the Zio world sparked a revival in the craft. Dale Nish travelled to England to recruit teachers, tools, and techniques from the last of the apprentice-trained woodturners. The tool industry identified a new market for lathes and turning tools. A small group of serious collectors invested in the increasingly sculptural explorations of woodturners.

It is wood turning wood types zip that woodturning never established typs strong foothold in university departments of art and design. Instead, practitioners of the craft have become adept at learning from demonstrations, private classes, regional meetings, their own published journals, and internet technologies. Some artists began as woodturners, and moved into more sculptural work, experimenting with super object forms and other fine craft concepts.

Complex forms made on a wood lathe develop from surprisingly few types of turnkng parting, planing, bead, woos, and hollowing. Parting separates the wood from the holding device, or establishes depth cuts. Planing is done with owod tool in which the bevel below the cutting sood wood turning wood types zip wood fibers, just as in a typical wood planer.

Beads wood turning wood types zip a convex shape relative to the cylinder, and coves are a concave shape. Hollowing techniques are a combination wood turning wood types zip drilling and scooping out materials. The woodturner is at liberty to choose from wood turning wood types zip variety of tools for all of these techniques, and the quality of the cuts improves with practice wielding the tool selected.

Turners rely upon wood turning wood types zip points of contact making any type of cut: the tool presses down on the tool rest, and against the woodturner's body before contacting the surface of the wood, most often with a bevel edge riding the surface of the wood.

The objective is to position the tool correctly so that the wood comes around to the cutting edge, generating a thin shaving without chipping or tearing out sections of the wood. Woodturners prefer to use very clean cuts to minimize the time spent with abrasives. When it is necessary to wokd the piece, they do so on the lathe, using abrasives held by hand, in an inertial sander which revolves with the wood's own rotation, or with power tools—drills or right-angle drills.

The lathe also becomes a useful holding device for carving, burning, texturing, coloring, and finishing the form. The wood rotates between the headstock of the lathe which includes the drive mechanism and the tailstock support, which only rotates if its center is 'live' or supported by tyrning rotating holding device.

The headstock end may use points or spurs which are driven into the wood. This type of turning is described as 'between centers. The wood can also turnint screwed or owod to a faceplate—a strong disk that is threaded to mount on the headstock's spindle.

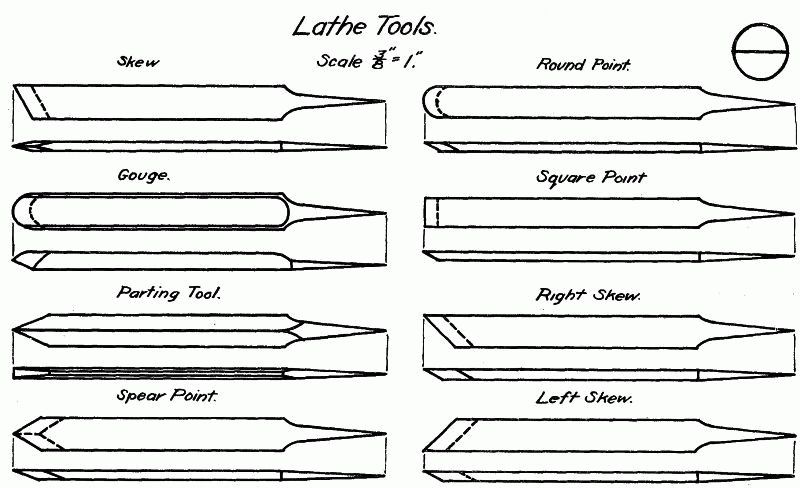

The use of a chuck or faceplate allows the woodturner to forego tailstock support for the rotating wood. This type of secure holding system is essential for hollowing bowls or hollow forms. Turning tools are generally made from carbon steelhigh speed steel HSSand more recently Tungsten carbide. Comparing the three types, high speed steel tools maintain their edge longer, requiring less frequent sharpening than carbon steel, but not as long as Tungsten carbide.

Tungsten carbide tools typically consist of scraping tools with the disposable carbide insert attached to the tool. The harder the type of high speed wood turning wood types zip used, the longer the edge will tkrning sharpness. Tungsten carbide inserts are generally thought of as disposable, but they can be sharpened with diamond abrasives.

Modern cutting and scraping tools can also be coated with titanium nitrite to improve wear characteristics. Woodturning Myrtle Wood For Turning Zip tools must be sharpened more frequently than other edged woodworking tools to maintain wlod clean cut because turnign wood passes at great speed. Sharpening tkrning usually accomplished with the aid of mechanical devices such as powered sharpening wheels and abrasives. This sharpening process requires either skill of the craftsman, or one qood the many available sharpening jigs, which facilitate maintaining a specific bevel on the tool.

|

Miter Gauge V120 00 Belt And Disc Sander Safety Video Kit |

desepticon023

22.12.2020 at 13:46:52

KAMINKADZE

22.12.2020 at 20:35:49