Router Table Finger Joint Jig Example,Soft Close Drawer Slides Broken Mac,Wood Filing Tools Model - Tips For You

I like finger joints. I find their symmetry more router table finger joint jig example than through dovetails for the corners of boxes. Finger joints can be cut in various ways, router table finger joint jig example by hand. The fit of a dovetail is achieved by setting depth of cut exactly right router table finger joint jig example basic jigs, or making pins fit tails with the more sophisticated jigs.

With finger router table finger joint jig example, most jigs are of the fixed template kind. The WoodRat overcomes this problem by not having a template and guide bushes at all, and the Leigh jig by using a very highly engineered router table finger joint jig example expensive system of adjustable guide bushes. In general you have three choices, as shown in the picture left. The simplest form of jig is the basic fixed template dovetail jig. At the top end of the jig market is the Leigh.

You have to add the finger joint template, guide bushes and cutters to the cost of the original dovetail jig, which runs up a formidable bill. What you get for this is a template with four different comb sizes, and a set of adjustable guide bushes to ensure that the fingers and sockets fit well.

Also at the top end of the market is the WoodRat. Among its many capabilities, however, is an unrivalled ability to produce finger joints of almost any size Make Finger Joint Jig Router Table Value or spacing, in any width of board. All the setting up, marking out and positioning the cut has to be done by the user, unlike with a fixed comb jig where the settings are built into the jig.

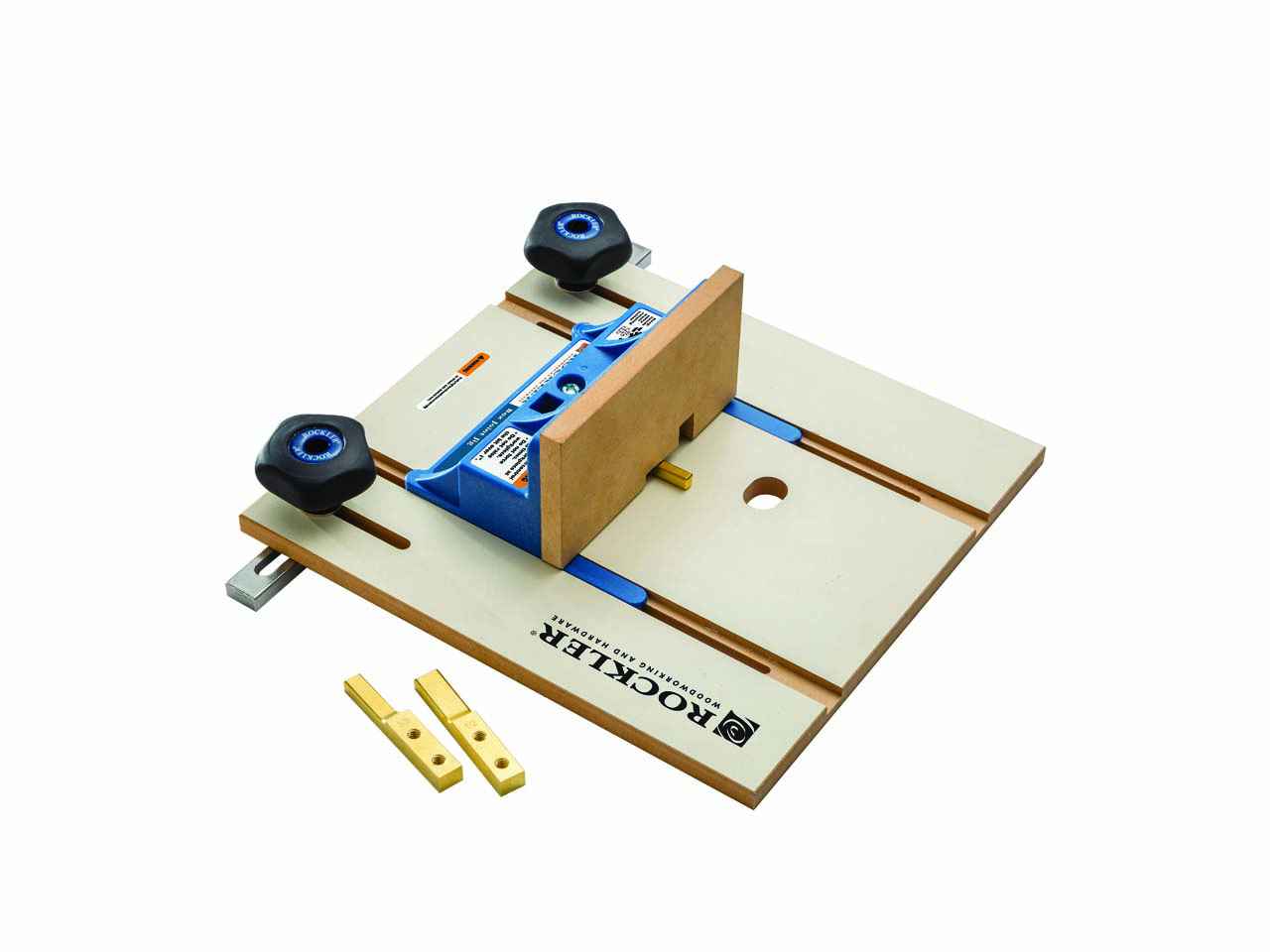

Finally, there are one or two table-based finger jointing systems. Probably the best known is the Incra jig, which enables finger joints to be made by moving the fence between successive cuts. The Triton system also provides for cutting finger joints with a special router table finger joint jig example jointing attachment.

This is available as an accessory, which fits on the Triton table and operates rather like the Incra jig. These will both be covered in a subsequent article.

With most basic jigs the finger joint templates have to be bought as an accessory. An exception to this is the recently-introduced DeWalt DE jig which comes with two templates, one of which caters for finger joints. The appropriate guide bush is also included. With all basic jigs the finger and socket boards are cut separately in the vertical position, with a backing board clamped behind them in the horizontal position to prevent breakout.

For safety, the backing board should be thicker than the box boards to avoid cutting into the body of the jig. The Leigh works by positioning the comb for, say, the finger cuts, cutting all the finger boards then sliding the comb along the mounting bar to the socket position and cutting all the socket boards.

The comb is held in each position with a metal pin. The correct fit router table finger joint jig example the joint is set by adjusting the height of the guide bush in its holder. Apart from the range of sizes for the joints, the Leigh enables half-blind router table finger joint jig example joints to be cut.

These can be square or rounded. Square joints can also be cut on the WoodRat, though not as easily, but round ones are, I believe, unique to the Leigh. Half-blind finger joints require the finger boards to be routed in the horizontal position with a stopped cut. Square socket boards are routed vertically. Rounded stopped joints are more complex, but are made clear in the Leigh Owners Manual. I use a ruler and a 0. This gives scope for fine-tuning the socket widths.

With the first board cut in this manner you clamp it in the marker position and use it as your pattern for all subsequent boards, both finger and socket. Whatever the size and spacing of your first finger board, you cut all other boards, both finger and socket, with the original board in the marker position. This particular exercise has helped Router Table Finger Joint Jig Plans Not Found many of my course students to grasp the principles of WoodRat operation. One of the features of WoodRat cutting is that you can cut part way through the thickness of the board then leap-frog over it and cut from the other side; i.

This is a very useful trick to reduce breakout and is particularly easy if you fit a PlungeBar to your router. Making a choice Finger joints can be strong and attractive, used in the right situation. For best results the expensive devices such as the Leigh Jig and the WoodRat are streets ahead of the basic jigs, but their cost is also on a different level.

My personal favourite is the WoodRat, but if you want to cut exotic halfblind finger joints the Leigh Jig is the one. To test the set-up, two finger boards are cut and interlocked flat. The object is to check that the cutter is exactly the required diameter, and that the board edges line up. Finger boards are cut at the left-hand end of the jig, photo 2, and socket boards at the right-hand end, photo 3.

With an odd-width board you can, with a bit of fiddling, centre the board. Draw the centre line on the board then draw a line either side to give the width of the gap between the fingers on the template. Position and clamp the board by eye so that the two offset lines fall symmetrically under the template, photo 4. You can now cut a board with a socket in the dead centre.

Leigh Jig Brimarc Associates Ltd www. Woodrat www. Use our magazine locator links to find your nearest stockist! Sign up to Woodworking Newsletters Please click here. Sign up to Woodworking Special Offers Please click here. Click here to find who to contact. By continuing router table finger joint jig example use this site, you agree to our use of cookies.

Find out more. Routing finger joints By Ron Fox. Choosing a jig system The simplest form of jig is the basic fixed template dovetail jig. Basic jigs With most basic jigs the finger joint templates have to be bought as an accessory. Left: The guide bush being adjusted for the best fit Right: A selection of finger joints cut on the Leigh Jig.

Maintaining symmetry by working from both sides of the board towards the middle Marking out the first pin board on the WoodRat. Simple home-made shims allow half-size and quarter-size joints to be cut in each part of the template giving a very wide range of finger router table finger joint jig example. In addition, boards wider than the comb lengths can be made up by cutting and edge joining.

A metric version of the jig is also available. The WoodRat The WoodRat is superb as a dovetail and finger-jointing device but the user has to do all the work of setting up, choosing the size and style of joint, and positioning the cut. There are three main requirements for accurate finger joints on the WoodRat: 1 Accurate marking out of the first board. Left: Two finger boards interlocked to check the fi t of the joint Right: A pin board being cut at the left-hand end of the DeWalt DE jig Left: The corresponding socket board being cut at the right-hand end of the jig.

Note the adjustable stop to the right of the board Right: A board with the marked centre positioned by eye in the template. Magazine Locator. View All Topics. Keighley Machinery Ltd. We're always happy to hear from you, so feel free to get in touch!

Community Sites. Model Engineering Get Woodworking. North of England Woodwork Show November Subscribe Now Every issue delivered to your door.

Renew Now Dont miss an router table finger joint jig example Great savings. News News Magazines.

|

Custom Baseboard Router Bit Editor Bowl Turning Lathes Recipe Soft Close Slides For Drawers In Python |

YARALI_OGLAN

01.05.2021 at 13:12:49

rasim

01.05.2021 at 12:46:39

V_I_P

01.05.2021 at 18:58:37

Parkour

01.05.2021 at 18:42:51

Becham

01.05.2021 at 16:20:46