Popular Mechanics Woodworking Plans Uk,Woodworking Plans Using Pallet Wood Texture,Woodworking Aprons With Pockets - PDF Books

A Worm Shoe is a non structural piece of wood whose 'sole' purpose is to protect the underwater wooden parts of a wooden boat keel, they need checking and replacing regularly. Ring Nails sometimes call Gripfast or ring shank, silicon bronze boat nails are renowned for their holding power.

Wood Screws are the most widely used and versatile fasteners used on wooden boats. Which type to use and how to use them.

A brief description of the most common Timber used for building Wooden Boats how to choose wood for your project boat. A brief guide to timber properties and wood, characteristics such as strength, stiffness and elasticity for choosing lumber for wooden boat building and restoration. I am building a replica of a 16' Garwood speedster and trying to find the best way to attach the stringers to the frames. The original stringers were.

Woodboat materials questions a Forum for Wooden Boat owners on wood, caulking, epoxy, sail cloth and related problems. Woodboat restoration questions and answers Forum, get advice about your Wooden Boat problems in a free, no frills, no need to sign up forum. Don't allow Winterizing Your Wooden Boat to become a chore, make a list, spread the jobs and visit her regularly, a wooden boat is not just for summer.

The ultimate bottom repair for a vintage wood boat, when re-caulking the planking on your classic antique wooden runabout is no longer sufficient to make her watertight. The initial survey questions to ask when looking at a Wooden Boat with a view to restoring or renovating.

Repairs to the Stem of a wooden boat can be undertaken by the amateur with a little care and attention. Privacy Policy. Advertising Policy. Cookie Policy. I am perfectly aware that the majority of Wooden Boat aficionados are sensible folk. However, I need to point out that I am an amateur wooden boat enthusiast simply writing in order to try to help other amateur wooden boat enthusiasts. DIY Wood Boat.

Home Free Boat Plans. Back Issues for Sale. This canoe is formed around plywood templates using redwood strips glued edge to edge. Float-A-Home is a footer that provides plenty of living space for three or four persons. This, coupled with a relatively low profile, makes it a very stable craft. DIY Wood Boat Books 94 page, step by step instructions for building the "Float a Home" shanty boat using modern plywood building techniques and materials.

Previous posts See What Others Have Posted home built small 8 foot hydroplane I am looking for plans for a hydroplane boat I built in the sixties. DIY Woodboat Building Questions Woodboat building questions a Forum for wooden boat building, plans, lumber, caulking compounds and other boat building problems. Worm shoe Sacrificial Protection for Wooden Boats A Worm Shoe is a non structural piece of wood whose 'sole' purpose is to protect the underwater wooden parts of a wooden boat keel, they need checking and replacing regularly.

Ring Nails for Marine Fastening. How to use Copper Rivets and Roves construction guide to fasteners on your wooden boat. I wanted it to have crisp lines and pleasing proportions, but most importantly it had to be functional. The bench is built out of construction lumber: clear Douglas fir, LVL laminated veneer lumber joists sawed into narrow strips then glued into a slab, and MDO medium density overlay , a form of plywood with a laminate surface.

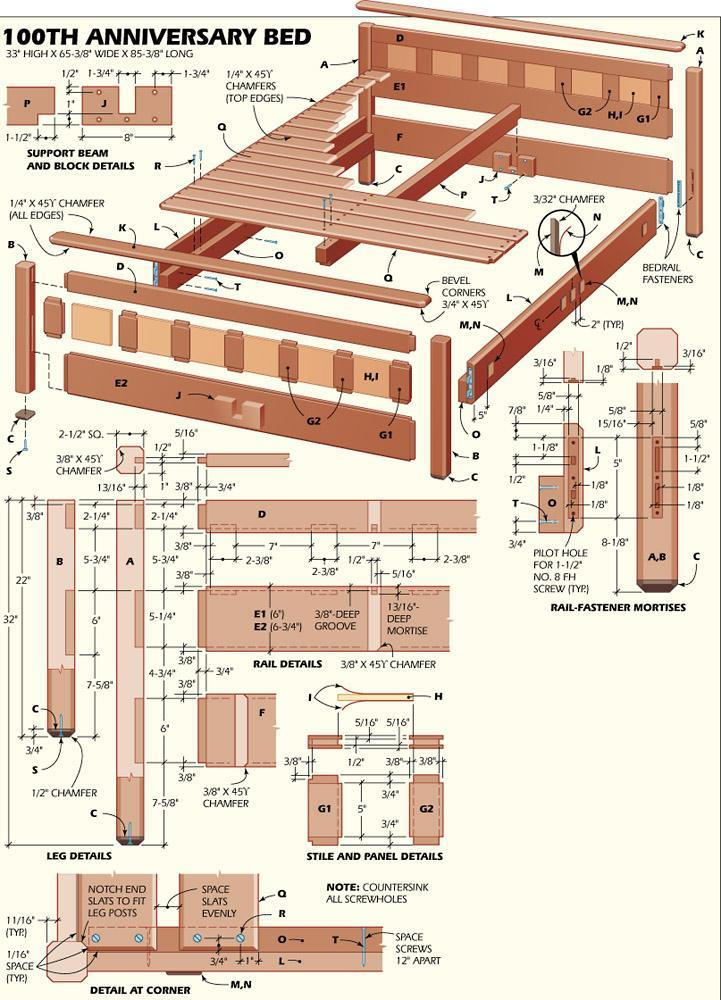

This is an ambitious project, no doubt. But, any experienced woodworker who owns a table saw and planer can build it.

Here's how to build one for yourself. How to Build a Workbench. Traditional A-frame toolboxes have been used by generations of tradespeople, including carpenters, plumbers, electricians and mechanics. So, we decided to show you how to build, not one, but five different versions of A-frame toolboxes, each customized for a particular type of work and worker. The open-top designs of A-frame toolboxes are preferred to boxes with hinged lids because they provide quick access to the tools.

Sure they may look a little rough and ready, but these boxes are workhorses, not works of art. Make an A-Frame Toolbox.

Box making is an essential skill for woodworkers of all skill levels. Once you hone your skills for making wooden boxes with tight joints and perfect proportions, you can create far greater things.

We asked three expert woodworkers to build a simple box to see how each would approach the task. Very differently, it turns out—despite giving them similar design guidelines.

The outside dimensions had to be 8 inches high x 12 inches wide x 16 inches long, and they could only use tools and materials found at their local home center. We ended up with three boxes with three distinctive joints—all equally awesome.

How to Make a Box. Every workshop needs a pair of sturdy sawhorses. And this thoroughbred pair is built from a few 2x4s. And these sawhorses strong, easy to build, and they conveniently stack for easy storage and transportation. Sawhorses are indispensable for use as a cutting and drilling station, for holding lumber or painting a door. And when topped with plywood, they become an instant worktable.

Built entirely out of 2x4s, this style of sawhorse is popular on construction sites and can be fastened together with Popular Mechanics Woodworking Plans Mac nails or screws. How to Build Stackable Sawhorses. Create an inviting outdoor living space with this easy-to-build backyard pergola. Before proceeding, finish all the plywood pieces. Clamp two opposing case sides edge-to-edge and mark each dado location with a pencil.

Be sure and mark the location of the case tops far enough down on the case sides, so that the tops provide a joining surface for the valance. Next, clamp a straightedge guide across the two sides. Slowly push the router along the guide, crossing both plywood pieces. If you plan to use biscuits to attach the face pieces, cut the necessary slots with a biscuit joiner [ 2 ]. For the tall sides, space the slots about 12 to 14 in. Cut three slots into shelves that are 18 in. I cut slots for No.

Since the bookcase has no back, you need to install a wood strip, or hanging rail, to screw each case to the wall. Cut the rail from a 1 x 3 or 1 x 4 to fit between the two case sides. Position it directly above the case top, and attach it to the case sides with glue and screws. Set each assembled case on its base [ 4 ] and use a 4-ft.

Next, secure the cases by driving 3-in. Use six strips total: two each at the bottom, center and top of the sides. Attach the neighboring case, if there is one.

Otherwise, clamp a side panel to the plywood spacers, creating 2-in. With the plywood cases installed, cut the mahogany face-frame parts, which include: 2-in. Before installing each mahogany part, sand it smooth, then apply a finish. Start with the horizontal base rail at the bottom of the bookcase. Hold the rail against the bottom shelf and mark onto the rail the center of each slot cut into the shelf.

Then use the biscuit joiner to cut corresponding slots into the back of the base rail. Apply carpenter's glue to the front edge of the bottom shelf, and the rear of the base rail.

|

Clamps For Husky Router Table 90 Wood Shop Jalan Besar Youtuber Carving Tools Kit Woodwork Limerick Review |

mcmaxmud

26.05.2021 at 22:27:51

SKANDAL

26.05.2021 at 21:46:14

KAROL88

26.05.2021 at 20:40:33

Lunatik

26.05.2021 at 14:56:54