Pocket Hole Jig Depth Code,European Style Hinges 40,Parts Of Mallet Hammer Zero,Gumtree Wood Turning Tools Kr - PDF Books

And I totally get this. Spending time perfecting difficult skills and procedures can be personally satisfying and enjoyable. Quiet time in the shop can be a centering, healing experience. These folks are more interested in completing a project they can use, rather than relishing in the shop experience.

We can awe at the work of others and get inspired by their approaches and goals. All boards have three types of surfaces. The important thing to always keep in mind, whether you are using pocket screws or not, is that screwing into the end grain of a board provides the weakest connection. The solution is to drive a screw at an angle so that it goes into the face grain or edge grain of each board. Additionally, this may actually be stronger than screwing straight into face grain, because the angle will ensure a longer portion of the screw will be embedded in the wood.

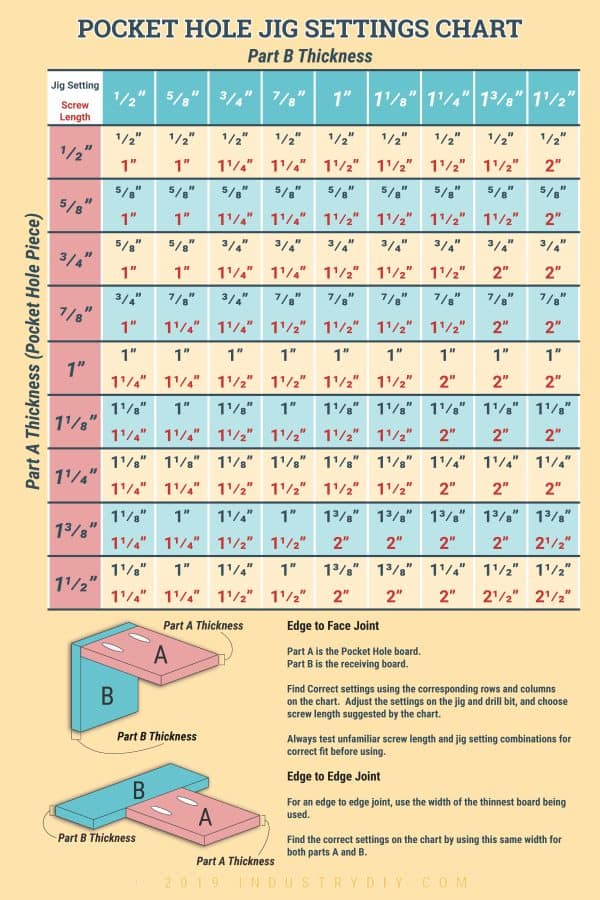

A regular screw would likely blast all the way through the pocket hole. There are other brands of pocket hole jigs, but the Kreg Jig is clearly the king and the only kind I have every used. There are two versions: the K4 and the newer K5. They both accomplish the same task, but the K5 is a little easier to set up and adjust. The K4 is less expensive though. I use the K5 jig. First, set this drill bit guide part to match the thickness of your board.

The drill bit comes with an adjustable collar that is held in place with a set screw. Use an Allen wrench to loosen it. Lock the collar by tightening the set screw. Again, this is an adjustment I rarely have to change. While not absolutely necessary, I highly recommend a vacuum attachment. Drilling pocket holes is messy and this removes the chips very effectively.

The jig had three holes spaced apart in such a way that helps you to bore holes whatever distance apart you like.

This allows for a lot of flexibility when positioning your holes. Anywhere you place them on the board it fine. Most of the time, you will use the jig to drill pocket holes in the ends of boards. Make sure the board the screw will be driving into is the face or edge grain board.

This is the correct way:. As you tighten the screw, it pulls the joint tightly together. The process is simple, but there are several things going on that make it possible.

That lets it turn easily inside the pilot hole instead of driving your two pieces of material apart. Second, the flat underside of the screw mates perfectly with the ledge at the base of the pocket. This way, the head pulls the joint tightly together to create a super-strong, lasting joint. Using the right kind of pocket-hole screw is critical to strong, long-lasting joints. Just drill a pocket hole…. An inside look at how pocket holes work.

July 14, Creating pocket-hole joints is a simple process.

|

Best Cnc Routers For Woodworking 5g Portable Woodworking Dust Collection Diy Mini Hand Planer Size Diy Woodworking Assembly Table Code |

G_E_R_A_I_N_8KM

20.09.2020 at 20:53:43

Genie_in_a_bottle

20.09.2020 at 17:43:41

BOREC

20.09.2020 at 16:56:11