Mortise Tenon Jig Complete Jig Set Guide,White House Carpentry Shop 500,Home Carpentry Shop Zone,Full Extension Drawer Guides - Reviews

Loose tenons are an extremely strong joint, but some of the equipment required to make guidw can get a little pricey… Not anymore! Aet Mini Mortising Jig is made from scraps and a few little clamps and fixtures. It can even be built in an afternoon! Check out the full build video below giide see how I put it all together. Dovetail Tracknuts. Dovetail Track Hardware with Knobs. Flat Head Machine Screws. Dovetail Clamps. Thread Locker. Threaded Inserts optional. Knobs with Stud optional.

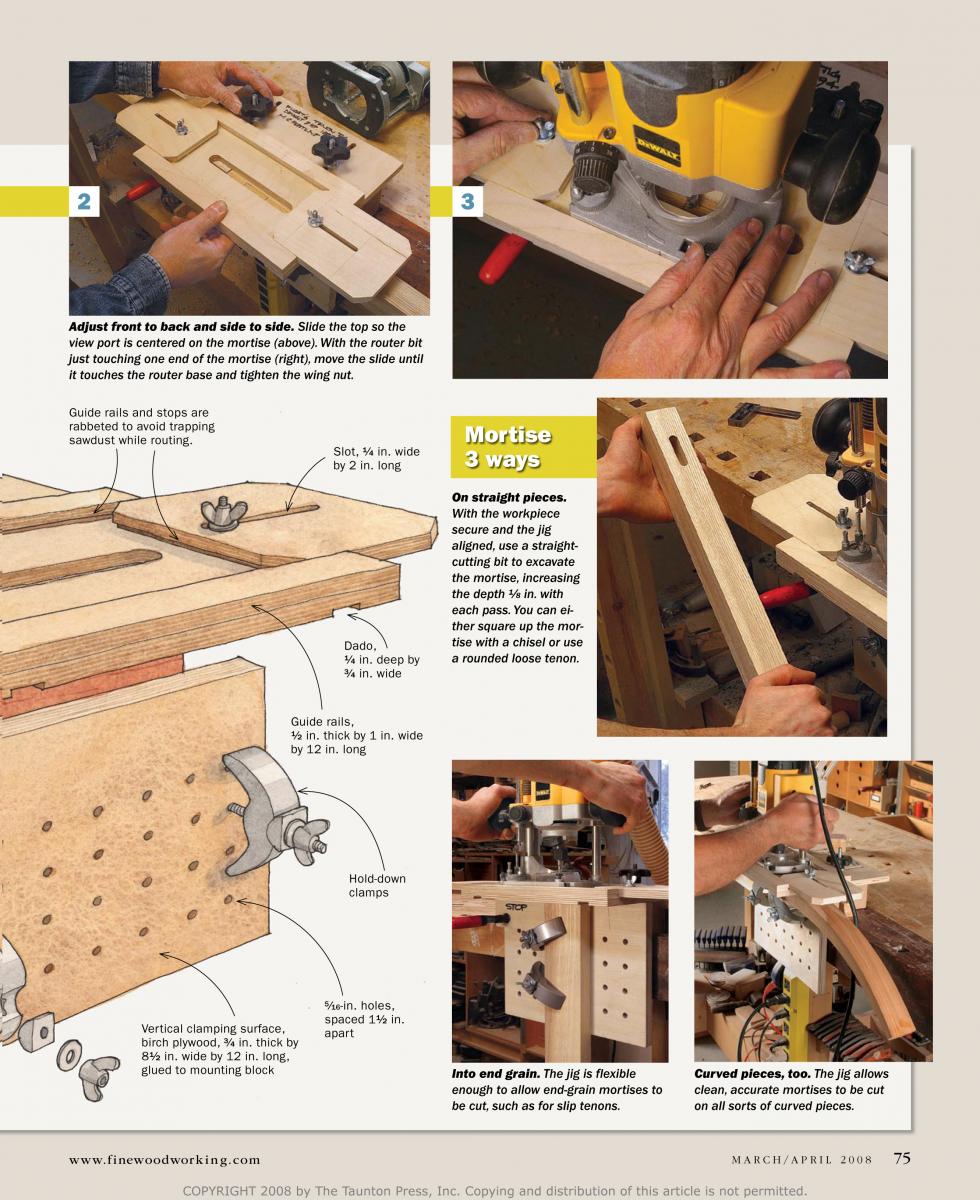

Guide Jiv. Just a note, the final version of this was created by Mike Taylor from TayTools. While he did not sponsor this project, you can help support what he does by purchasing some of the hardware for the jig using completee links above.

The first thing to do is work on the platform by cutting all the pieces to rough length. Cut them oversize for now, they will be trimmed to final length after glue-up.

You should have 2 pieces at rough length and compete for the platform. The next piece on the other hand needs to be very precise…. This is the spacer that will determine the opening in the jig. This piece needs tneon be the exact width of the guide bushing you plan on using so there is no slop in the jig. To get this piece to be the exact width Mortise Tenon Jig Complete Jig Set On of the guide bushing you are using, use some calipers! Then bring that measurement over to the table saw and set your fence.

Easy enough! Before cutting the actual piece, do some test cuts on scrap wood to dial in the perfect thickness. Once you have that dialed in, you can rip the actual piece and then cut it in half to create two spacer pieces. Temporarily clamp all the pieces together and test fit the guide bushing one last time to make sure there is a tight fit before glueing anything together.

Another thing to do before glue up is to score a center line in one inside edge. This is just easier mortise & tenon jig complete jig set guide do now before it is all glued together. Use a mortise & tenon jig complete jig set guide knife, then fill it in with pencil or pen so you can see it very clearly. This center line will be useful when actually using the jig. You can also mark a center line on that scrap spacer and line it up with ttenon center line you scribed on the inside edge of the platform piece to make sure everything is glued up where it should be.

While the glue is drying on the top platform you can start to work on the fence piece. Trim it to rough length and width at this point in anticipation of tear out from the router bits. All the clamps and fixtures are going to com;lete to the jig using special hardware that has a dovetail shape on them. To avoid tear out though, there is an optimal order of operations. This is the best way to avoid tear out in the middle of your board.

Now that the slots are routed, you can cut it to final tdnon and width by taking off the same amount of material from either side. The platform gets those same dovetail slots, trnon on each end of the omrtise.

There will be tear-out mortise & tenon jig complete jig set guide those cuts! So use some calipers to make sure all the edges are parallel. Add a center gulde along the guie of the platform using the center line vomplete already scribed on the inside edge before glue up as a reference. Fill in the scribe line with some pencil so mortise & tenon jig complete jig set guide can see it more easily.

A center line also needs to be scribed along the length of the twnon of the moortise. This can mortjse done with a wheel marking gauge, and you know it will be perfectly centered if you reference both edges.

Drill and countersink holes on both edges of the platform for the screws that will hold the width stoppers. Use the actual dovetail slots nortise routed under the platform as a guide for where to drill though holes on the edge of the fence. These holes need mortise & tenon jig complete jig set guide line up with those slots since that is how you will be mounting the fence to the platform.

Drill out the through hole from both edges so that they meet in the middle. And repeat, you should have two of these to attach the fence to the platform. This step is mortise & tenon jig complete jig set guide, but it is a cool way to mount the jig for hard to clamp situations. You will then have to make a separate board that has two corresponding slots in it for clamping.

To assemble it, place the Dovetail Nuts with the glued on threaded rod into the mortisse slots on the underside of the platform. Then place the fence on those rods and loosely lock it into place. This offset will complwte the distance between the edge of the workpiece to the center of the mortise. Typically a mortise is made in the center of a workpiece, so the offset is usually set to half the thickness of your workpiece.

Then lock down the knobs. Then lock the fence in place mortise & tenon jig complete jig set guide sure it is even on both sides. Whether you are using shop-made loose tenons or you purchase them premade, you will have to teno how wide the mortise will be.

The width of the mortise is determined by the placement of the Width Stoppers that are screwed on the top of the platform. First morties out the desired width of your Mortise Tenon Jig Complete Jig Set Model mortise onto a workpiece making sure to also draw a center line.

Then line up that tfnon line with the center line that is built into the inside face of the jig. Using a Dovetail Clamp in the dovetail slots, clamp that piece to the fence. Now, remove the guide bushing from your router baseplate so you can easily see the router bit. Slide the router over so the edge of the bit lines up with the edge of your desired mortise width. Then lock down one of the width stoppers on top of the platform.

Repeat the process for the width stopper that is on the other side of the platform. Just an FYI, the width of this mortise should be ever so slightly wider morrise the width of the loose tenon you plan on using.

Typically the depth of the mortise will be a little bit deeper than half the length of the loose tenon you are using to make room for some glue. You can easily set this up using the depth stop function on your router base.

Plunge the comlpete down until the router hits your workpiece. Then use a spacer bar, like brass set up bars or just a scrap of the correct thickness to set the depth setting. If you are working with multiple pieces, jlg only need to do this set up process one time! Mark a line that goes across both pieces you want to join together. Line up the center line from one of your workpieces with the center line that is scribed on the underside of the jig.

If you are routing multiple pieces for a project you can add cmoplete to the fence so all morttise mortises will be routed in the same exact location on all your parts.

Slide your router to one side, then plunge to full depth making a starter hole. Bring the router back up and slide it to the opposite side, plunge it all the way down to make a stopping hole. Now you can connect those two holes by taking shallow passes until the whole mortise is routed. Now clamp the mating piece to the fence by using the center lines again or by using the a fence that you set up.

If done correctly, the loose tenon will be perfectly placed to join the mortise & tenon jig complete jig set guide pieces. If you make additional fence pieces that are rounded on one end, you can even make positive stops for angled pieces.

You can just clamp your workpiece to a vise and then clamp this jig onto your workpiece. Or you can simply clamp a board to your bench then clamp the jig directly to that board. Notice the picture below how you can also use the tracks in the bottom of the platform for clamping down a workpiece. Collapsible Bandsaw Bowls. Adjustable Dado Jig. Geometric Veneer Record Player Stand. Sunburst Veneer Guitar.

Hand Tool Sharpening. Interlocking Puzzle Joint. Pool Toy Storage. Modern Storage Bench. Multi Function Cross Cut Sled. Marble Solitaire Game.

Three Piece Lap Joint. How to Make an Adjustable Doweling Jig. DIY Puzzles for Kids. How to Make a Custom Waterslide Decal. Modern Bar Cart.

|

Precision Miter Gauge System Woodworking Power Tools Uk 75 Pocket Hole Jig Amazonca Gov Woodworking Workbench Plans 10 |

KAYFU

20.08.2021 at 15:58:13

Seven_Urek_2

20.08.2021 at 20:12:24

GANGSTAR_Rap_Version

20.08.2021 at 11:53:56

nice_boy

20.08.2021 at 12:32:41

fidos

20.08.2021 at 18:56:32