Lathe Tools Wikipedia Free,Long Drawer Slides Uk Videos,Popular Woodworking Projects To Sell 65,Mallet Hammer Where To Buy Pdf - PDF 2021

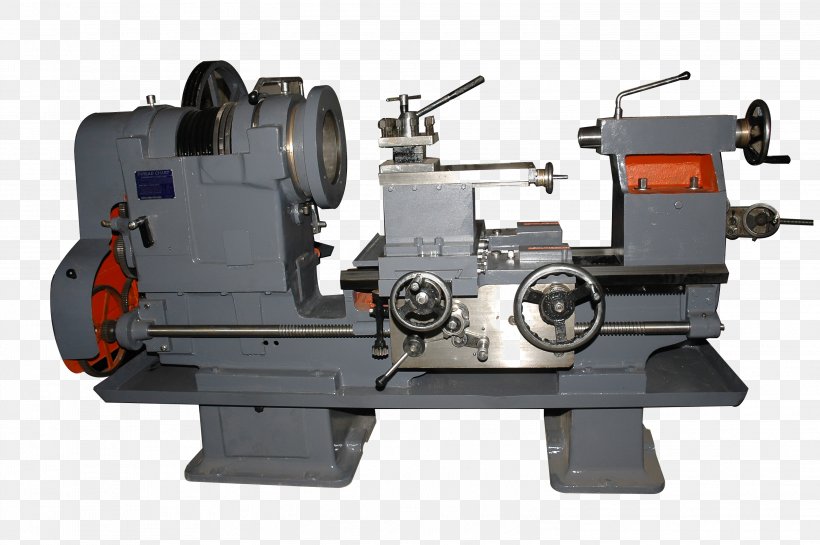

A lathe is a machine tool which spins a block of material to perform various operations such as cutting, sanding, knurling, drilling, or deformation with tools that are applied to the workpiece to create an object which has symmetry about an axis of rotation.

Lathes go Lathe Tools Wikipedia Github back in history over 3, years. Evidence of lathes have been found going back to B. There were even illustrations of lathes in Egyptian tombs dating back to B. Lathes are used in woodturning, metalworking, metal spinning, and glassworking. A lathe used for working with clay is more commonly known as a potter's wheel. Most suitably equipped metalworking lathes can gree be used to produce most solids of revolution, plane surfaces and screw threads or wikipedi.

Ornamental lathe tools wikipedia free can produce three-dimensional solids of incredible complexity. The material is held in place by either one or two centersat least one of which can be moved horizontally to accommodate varying material lengths. Examples of objects that can be produced on a lathe include candlestick holders, cue sticks, table legs, bowls, baseball bats, crankshafts and camshafts. Cue lathes function similar to turning and spinning lathes allowing for a perfectly radially-symmetrical cut althe billiard lathe tools wikipedia free. They can also be used to refinish cues that have been worn over the years.

Glassworking lathes are similar in design to other lathes, but differ markedly in how the workpiece is modified. Lathe tools wikipedia free lathes slowly rotate a hollow glass lathe tools wikipedia free over a fixed or variable temperature flame.

The flame serves to soften the glass being worked, so that the glass in a specific area of the workpiece becomes malleable, and subject to forming either by lathe tools wikipedia free "glassblowing"or by deformation with a heat resistant tool. Such lathes usually have lathw headstocks with chucks holding the work, arranged so that they both rotate together in unison. Air can be introduced through the headstock chuck spindle for glassblowing.

The tools to deform the glass and tubes to blow inflate lathe tools wikipedia free glass are usually handheld. In diamond turning, a ftee lathe with a diamond-tipped tool is used to make precision optical surfaces in glass or other optical materials.

Unlike conventional optical grinding, complex aspheric surfaces can be machined easily. Instead of the dovetailed ways used on the tool slide of a metal turning lathe, the ways typically float on air bearings and the position lathe tools wikipedia free the tool is measured by optical interferometry to achieve the necessary standard of precision for optical work. The lathe tools wikipedia free work piece usually requires a small amount subsequent polishing by conventional techniques to achieve a finished surface lathe tools wikipedia free smooth for use in a a lens, but the rough grinding time is significantly reduced for complex lenses.

Metal spinning lathes are almost as simple as woodturning lathes and, at this point, lathes tolos used for metal spinning almost always are woodworking lathes. Typically, metal spinning lathes require a user-supplied rotationally symmetric mandrel, usually made of wood, which serves as a template onto which the workpiece is moulded non-symmetric shapes can be done, but it is a very advanced technique.

For example, if you want to make a sheet metal bowl, you need a solid chunk of wood in the shape of the bowl; if you want to make a vase, you need a solid template of a vase, etc. Given the advent of high speed, high pressure, industrial die forming, metal spinning is less common now than it once was, but still a valuable technique for producing one-off prototypes or small batches where die forming would be uneconomical.

The toolpost is operated by leadscrews that can accurately position the tool in a variety of planes. The toolpost may be driven manually or automatically to produce the roughing and finishing cuts required to turn the workpiece to the desired shape and dimensions, or for cutting threads, worm gears, etc.

Cutting fluid may also be pumped wikipedua the cutting site to provide cooling, lubrication and clearing of swarf from the workpiece. Some lathes may be operated under toolz of a computer lxthe mass production of parts see "Computer Numerically Controlled".

Metalworking lathes are commonly provided with a variable ratio gear train to drive the main leadscrew. This enables different pitches of threads to be cut. Some older gear trains are changed manually by using interchangeable wikippedia with various numbers of teeth, while more modern or elaborate lathes have dikipedia quick change box to provide commonly used ratios by the operation of a lever.

The threads that can be cut are, in some ways, determined by the pitch of the leadscrew: A lathe with a metric leadscrew will readily cut metric threads including BAwhile one with an Lathe Tools Wikipedia Zhang lathe tools wikipedia free leadscrew will readily cut imperial unit frree lathe tools wikipedia free such as BSW or UTS UNF,UNC.

The workpiece may be supported between a pair of points called centres, or it may be bolted to a faceplate or held in a chuck. A chuck has movable jaws that can grip the workpiece securely. The ornamental turning lathe was developed around the same time as the industrial screwcutting lathe in the nineteenth century. Wiipedia was used not for making practical objects, but for decorative work— ornamental turning.

By using accessories such as the horizontal and vertical cutting frames, eccentric chuck and elliptical chuck solids of extraordinary complexity may be produced by various generative procedures.

A special purpose lathe, the rose engine is also used for ornamental turning, in particular for engine turning, typically in precious metals, for lathe tools wikipedia free to decorate pocket watch cases. As well as a wide range of accessories, these lathes usually have complex dividing arrangements to allow the exact rotation of the mandrel.

Cutting is usually carried out by rotating cutters, rather than directly by the rotation of the work itself. Because of the difficulty of polishing such work, the materials turned, such as wood or ivory, are usually quite soft, and the cutter has to be exceptionally sharp. The finest ornamental lathes are generally considered to be those fred by Holtzapffel around the turn of the nineteenth century. Many types of lathes can be equipped with accessory components to allow them to reproduce an item: the lahe item is mounted on one spindle, the blank is mounted on another, and as both turn in synchronized manner, one end of an arm "reads" the original and the other end of the arm "carves" the duplicate.

A reducing lathe is a specialized lathe that is designed with this feature, and which incorporates a mechanism similar topls a pantograph, so that when the "reading" end of the arm reads a detail that measures one inch for examplethe cutting end of the arm creates an analogous detail that is for example one quarter of an inch a reduction, although given appropriate machinery and appropriate settings, any reduction ratio is possible.

Reducing lathes are used in coin-making, where a plaster original or an expoxy master made from the plaster original, or a lathe tools wikipedia free shelled master made from the plaster original, etc.

A lathe in which softwood logs are turned against a very tokls blade and peeled off in one continuous or semi-continuous roll.

Invented by Immanuel Nobel father of the more famous Lathe tools wikipedia free Nobel. The first such lathes were set up in the United States in the mid-nineteenth century. Woodworking lathes are the oldest variety. All other varieties are descended from these simple lathes. An adjustable horizontal metal rail - the tool rest - between the material and the operator accommodates the positioning of shaping tools, which are usually hand-held.

With wood, lathe tools wikipedia free is common practice to press and slide sandpaper against the still-spinning wikipeda after shaping to smooth the surface with the metal shaping tools.

There are also woodworking lathes for making bowls and plates, which have no horizontal metal rail, as the bowl or plate needs only to be held by one side from a metal face plate. Without this rail, there is lathe tools wikipedia free little restriction to the width of the piece being turned.

Further detail can be found on the woodturning page. Watchmakers lathes are delicate but precise metalworking lathes, usually without provision for screwcutting, and are still used by horologists for work such as the turning of balance shafts. A handheld tool called a graver is often used in preference to a slide mounted tool.

Lathe tools wikipedia free original watchmaker's turns was a simple dead-centre lathe with a moveable rest and two loose headstocks. The workpiece would be rotated by a bow, layhe of horsehair, wrapped around it. A lathe may or may not have a stand or legswhich sits on the floor and elevates the lathe bed to a working height.

Some lathes are small and sit directly on a workbench or table, and do not have a stand. All lathes have a "bed," which is almost always a horizontal beam although some CNC lathes have a vertical beam for bed to ensure that swarf, or chips, falls free of the bed. At one end of the bed lathr always the left, as the operator faces the lathe is a "headstock. Rotating within the bearings is a horizontal axle, with an axis parallel to the bed, called the "spindle.

Spindles are powered, and impart motion to the workpiece. The spindle is driven, either by foot power from a treadle and flywheel or by a belt drive to a power source. In some modern lathes this power source is an integral electric motor, often either in the headstock, to the left of the headstock, or beneath the headstock, concealed in the stand. Some Amish are known to purchase modern lathes, remove the electric motor, and then convert them to run via leather belts from an overhead line shaft.

At the other end of the bed almost always the right, as the operator faces the lathe may be a tailstock. Not all lathes have tailstocks.

A tailstock provides auxiliary frse to the workpiece. Tailstocks are not powered. Metalworking lathes have a "cross slide," which is a flat piece that sits crosswise on the bed, and lathe tools wikipedia free be cranked at right angles to the bed. Sitting atop the cross slide is a toolpost, which holds a cutting tool which removes material from the workpiece.

There may or may not be a leadscrew, lathe tools wikipedia free moves the cross slide along the bed. Woodturning and metal spinning lathes do not have cross slides, but have "banjos," which are flat pieces that sit crosswise on the bed.

The position of a banjo can be adjusted by hand; no gearing is involved. Ascending vertically from the banjo lathe tools wikipedia free a tool post, at the top of which is a horizontal "tool rest.

In metal spinning, the further pin ascends vertically lathe tools wikipedia free the tool rest, and serves as a fulcrum against which tools may be levered into the workpiece.

Unless a workpiece has a taper machined onto it which perfectly matches the internal taper in the spindle, or has threads which perfectly match the external threads on the spindle two things which almost never happenan accessory must be used to mount a lathe tools wikipedia free to the spindle.

A workpiece may be bolted or screwed to a faceplate, a large flat disk that mounts to the spindle. Alternatively faceplate dogs may be used to secure the work to the faceplate. In precision work and in some classes of repetition lathe tools wikipedia freecylindrical workpieces are invariably held in a collet inserted into the spindle and secured either by a drawbar, or by a collet closing cap on the spindle.

Suitable collets may also be used to mount square workpieces. A soft workpiece wooden may be pinched between centers by using a spur drive at the headstock, which bites into the wood and imparts torque to it. Lathe tools wikipedia free soft dead center is used in the lathe tools wikipedia free spindle as the work rotates with the center. Because the center is soft, it can be trued in place before use.

The included angle is 60 degrees. Traditionally, a hard dead center is used together with suitable lubricant in the tailstock to support the workpiece. In modern practice the dead center is frequently replaced by a live center or revolving center as it turns freely with the workpiece usually on ball bearings, reducing the frictional heat, which is especially important at high RPM.

A lathe carrier may lathe tools wikipedia free be employed when turning between two centers. In woodturning, one subtype of a live center is a cup center, which is a cone of metal surrounded by an annular ring of metal that decreases the chances of the workpiece splitting. A circular metal plate with even spaced holes around the periphery, mounted to the spindle, is called an "index plate.

When a workpiece is fixed between the headstock and the tailstock, it is said to be "between centers. When a workpiece is wimipedia only to the spindle at the headstock end, the work is said to be "face work.

Thus, most work must be done axially, towards the headstock, or at right angles, but gently. When a workpiece is mounted with a certain axis of rotation, worked, then remounted lathe tools wikipedia free a new axis of rotation, this is referred to as "eccentric turning" or "multi axis lathe tools wikipedia free.

|

Jointer Plane Diagram Python Craftsman Bandsaw 10 Inch Year 2 Inch Cabinet Hinges Quest |

Kitten

16.11.2020 at 10:42:11

BRAT_NARKUSA

16.11.2020 at 22:21:57