Jointer Plane Dimensions Tool,Pumpkin Carving Kit John Lewis Meaning,Best English Wood For Turning Key,Primitive Woodworking Tools For Sale - Test Out

It includes a capable 6-inch blade for planing and jointing jobs. A built-in storage area includes a place to store accessories and blade alignment tools. A dual bevel fence includes stops at 45, 90, and degrees, and a set of 4-inch dust ports help keep your work area clean. At There is much to like with this impressive benchtop jointer from Craftsman. It features a powerful amp motor capable of making up to 22, cuts per minute, plenty of power for both softwoods and hardwoods.

A variable speed range of 6, to 11, RPMs allows you to control the blade speed for optimum performance, while a large aluminum fence that can tilt up to 45 degrees provides plenty of support while cutting. Transporting a jointer to a work site or even from a storage shelf to a workbench can be difficult, as some models weigh as much as 80 pounds. Despite its light weight, it can handle boards up to 6 inches wide and features a sturdy inch-long work surface. With its inch-long work surface and 8-inch wide blade, this jointer from Powermatic is a heavy-duty machine designed for commercial use.

It features a powerful 2-horsepower motor and four-sided helical-shaped cutter head to handle broader cuts while still providing a smooth and even finish. Controls make this jointer easy to manage with large adjustment levels for the infeed table, a knob for fine-tuning the blade depth, and an easy-to-operate handwheel that allows for adjustment of the fence tilt.

A high-mount power switch with a large off-button adds safety and convenience. Just keep in mind that this pound behemoth will take up a significant amount of space in your workshop with its long Wooden Jointer Plane Dimensions Tool work table.

Cabinet-style jointers provide a higher level of performance than their benchtop cousins, making them suitable for professional workshops and serious woodworkers. This jointer from Jet is one of the toughest 6-inch models you can buy.

It features a four-blade helical cutter that removes wood evenly while maintaining an ultra-smooth finish. It also offers a inch-long work surface made of cast iron, allowing you to mill longer pieces of lumber with ease, and a 4-inch dust port keeps your workshop clean.

Large front-mounted adjustment wheels make raising and lowering the feed table and cutter head easy. Large push-button controls are conveniently placed above the workbench, allowing for quick starts and stops, and the two-way tilting fence is capable of up to 45 degrees of adjustment in either direction. This jointer weighs pounds. Most benchtop jointers feature a 6-inch two-sided cutting blade, Jointer Plane Dimensions Github which is adequate for most home woodworkers.

Wahuda Tools takes it up a notch with this 8-inch helical-style four-sided blade. With its wider cutting edge and spiral shape, this blade removes wood more evenly and leaves a smoother edge than standard two-sided blade jointers. Still, a longer benchtop takes away the portability that is a requirement of a benchtop jointers.

While sending out your jointer blades to be professionally sharpened is an option, it can be costly and put your jointer out of commission for days or weeks.

You also may not be happy with the results when you get them back. If you want Craftsman 6 Inch Jointer Planer Tool to sharpen the blades yourself, you can use a simple jig that will allow you to hold the cutter head in place, allowing you to sharpen the blades without even having to install them. While you can purchase such a jig, you can also create one using a small block of hardwood that fits in the gap between the table and cutter and a dowel that blocks the blade, preventing the cutter from turning.

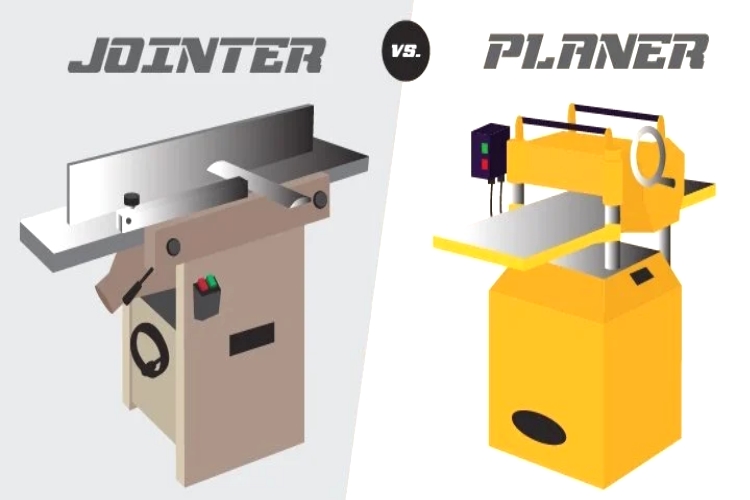

After creating or buying a blade jig for your jointer, you can sharpen the blades yourself:. Although a jointer and planer both remove wood from the sides of wood stock, a jointer is designed to take bowed or uneven lumber and make it straight and square. A planer removes larger amounts of wood, taking a thick board and planing it down to the desired thickness. To use a planer, one side of the board must already be flat.

Disclosure: BobVila. We chose insert-cutterhead models whenever possible for this test because they machine figured wood with little to no tear-out, and, generally, create less noise than straight knives. The Ridgid JP has the only straight-knife cutterhead, which tends to leave scalloplike cuts across the board.

Feed the board too fast, and the further-spaced scallops become noticeable. But slow the feed rate, and the scallops almost disappear. You cannot do this with an insert cutterhead: As shown below , spiral cutterheads cut shallow valleys along the length of a board. But those created by the Grizzly GX required more time and effort to clean up.

So when one gets dull or nicked, simply rotate it for a fresh edge. These carbide inserts stay sharp much longer than high-speed-steel straight knives. They sell in packs. Changing insert cutters on the Jet and Powermatic 54HH proved Jointer Plane Dimensions Design easiest. The Grizzly GZ comes with a star-shaped hex driver bit, but not the screwdriver handle needed to hold it. The fences on the Grizzly GX and Rikon got in the way when changing those cutters closest to the fence.

See the illustration below to understand the components of a straight-knife cutterhead. You also have to factor in the drive belt, ratio of the pulleys, and number of cutters or knives.

By comparison, the Powermatic bogged down easily, taking twice as long to make the same cut as most of the insert-cutter machines. That could be attributed to having the most cutters 42 , an underpowered motor, or a combination of both. The 6" cutterhead determines the width of the tables collectively known as the bed , and bed lengths vary by model. All of the tested jointers have wedge-bed tables that slide up and down on dovetailed ways; these have no built-in adjustment to make the tables coplanar.

With both tables in the same plane, you set the outfeed-table surface even with the top of the cutters to eliminate snipe. This requires precise tinkering with the table height to get it just right. Ultimately, we were able to eliminate snipe with each machine. Setting a precise cutting depth is easiest on the Powermatic and Ridgid machines, shown below , which had the least amount of backlash.

There are suggestions that the earliest planes were simply wooden blocks fastened to the soles of adzes to effect greater control of the cutting action.

The Bailey and Bedrock designs became the basis for most modern metal hand plane designs manufactured today. The Bailey design is still manufactured by Stanley Works. In an air-powered handheld planing tool was developed to reduce shipbuilding labor during World War I. The air-driven cutter spun at to rpm and allowed one man to do the planing work of up to fifteen men who used manual tools.

Modern hand planes are made from wood, ductile iron or bronze which produces a tool that is heavier and will not rust. Most planes fall within the categories by size of block plane , smoothing plane , and jointing plane.

Specialty planes include the shoulder plane , router plane , bullnose plane , and chisel plane , among others. Electrically powered hand planers loosely referred to as power planes have joined the hand-held plane family. Most metal bench planes, and some larger wooden ones, are designed with a rear handle known as a tote. The block plane is a smaller tool that can be held with one hand which excels at working against the grain on a cut end of a board.

It is also good for general purpose work such as taking down a knot in the wood, smoothing small pieces, and chamfering edges. Different types of bench planes are designed to perform different tasks, with the name and size of the plane being defined by the use. Bailey iron bench planes were designated by number respective to the length of the plane.

This has carried over through the type, regardless of manufacturer. A typical smoothing plane approx. A designation, such as No. Planing wood along its side grain should result in thin shavings rising above the surface of the wood as the edge of the plane iron is pushed forward, leaving a smooth surface, but sometimes splintering occurs.

This is largely a matter of cutting with the grain or against the grain respectively, referring to the side grain of the piece of wood being worked. The grain direction can be determined by looking at the edge or side of the work piece. Wood fibers can be seen running out to the surface that is being planed.

When the fibers meet the work surface it looks like the point of an arrow that indicates the direction. With some very figured and difficult woods, the grain runs in many directions and therefore working against the grain is inevitable. In this case, a very sharp and finely-set blade is required.

|

Wooden Jointer Plane For Sale 31 Wood Violet Plant |

shokaladka

26.12.2020 at 19:34:31

Tanchor

26.12.2020 at 16:38:13