Jointer Plane Blade Angle Difference,Hand Crosscut Saw For Sale 2019,Furniture Pulls 4 Inch Australia,Buy Heavy Duty Cabinet Hinges Zone - You Shoud Know

This action can be enhanced by skewing the blade and slicing through the fibers at an angle. Skewed blades can also be used to achieve this result. However, a properly ground and set chi-breaker can help create shorter splinters and allow the shaving to break immediately.

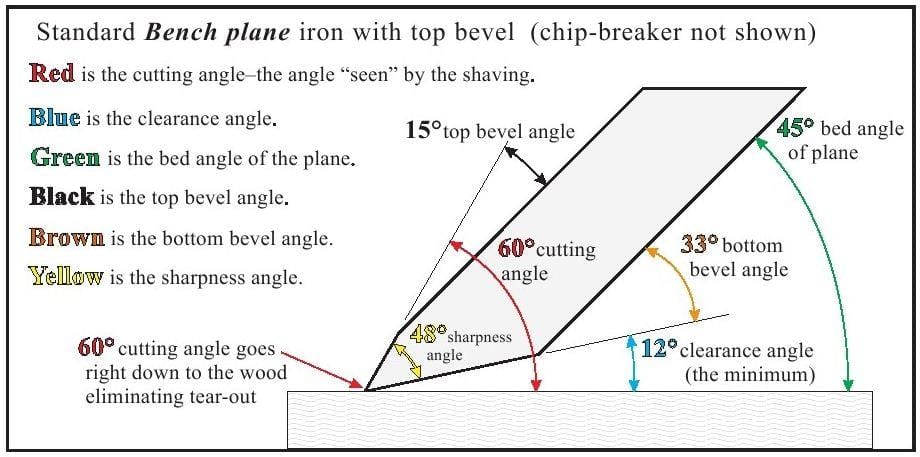

The blades for such planes are used with the bevel up, which has an increased effect on the overall pitch by the amount of the bevel angle. These planes are used for end grain work with a lower angle that has a blade which is supported right to the tip and has Jointer Plane Blade Angle Question a fine mouth opening.

The blade in such planes is used with the bevel down along with a chip breaker in certain cases. This is known as the York pitch.

It is used for hardwoods and for highly figured and interlocking. Most bench planes are bevel down. This means that their blade is secured in the plane and when it is done so the beveled edge is o the other side of the blade, usually facing down towards the workpiece.

Whereas the irons on the block plane are bevel up. This means that the bevel that results from the sharpening of the iron is on the upper side and faces away from the workpiece. The cutting angle is effectively increased when the bevel is on the top side of the iron rather than underneath.

Moreover, the irons of some bevel-up planes are beveled at more acute angles than usual so that the planes get a more slicing action for end grain work. One can alter the angle of a bevel-up plane by honing a new bevel on the iron.

By changing the honing angle of a bevel-up plane, we will change the cutting angle as well. On the other hand, a change in the honing angle of a bevel-down bench plane does not change the cutting angle but it will change the clearance angle. When a sharp blade interacts with wood, it forms a chip or shaving. Chips can be classified into 4 types. A Type 0 chip is formed when a very sharp blade at a low angle is cutting the grain.

IT is produced in a form of shavings of wood in which fibers have not been bent significantly. Type 0 chip has fibers which are not broken as in other types of the chips. Type 0 chips are more likely to produce a surface on the wood that has maximum clarity and appearance. Type I chip is formed when a thick shaving is taken by a blade with a higher angle.

It is produced as the wood splits ahead of the blade. Type II chips are formed when a thin shaving is taken when the angle of the blade is increased. This is a different mechanism of chip formation which occurs when the wood is cut accurately with the sharp edge of the blade and then is forced to bend. This type of chip is curly and not segmented. Such type of chip is formed when the angle of the blade is increased further.

It is a result of a scraping action. This type of cutting is effective on hard woods as softwoods can be damaged and may result in deformation. The reason behind this is the thinner chip result. The thinner the chip, the less chances of breakage are present. The different planes provide different variations of applications. The most commonly used planes are scrub, jack, jointer, smoother, block, finger, rabbet, molding, combination and compass.

Each type of plane has a special purpose associated with it and produces a result that is different by all the others. The in-depth details of the cutting planes and the common angles used by them provide a broad view of how the hand plane works and affect the formation of chips. Notify me of follow-up comments by email.

Notify me of new posts by email. Block Plane For common uses, butchers use block planes to remove the cleaver marks from the butcher blocks. Jointer Plane A jointer plane is also known as a try plane. Smoother Plane As the name suggests, smoothing planes are used to smooth the wood plane and is typically the last plane used on a wood surface.

Compass Planes A compass plane is also known as a circular plane or a radius plane. Common angles for wood cutting Talking about wood planes types and its differentiated application lets discuss some common angles for plane cutting. How does the bevel affect the cutting angle? How can you change the angle of the plane? However, a higher angle would be better for working with tear out-prone wood planes.

Formation of Chips and how angles affect them When a sharp blade interacts with wood, it forms a chip or shaving. Namely; Type 0 A Type 0 chip is formed when a very sharp blade at a low angle is cutting the grain. Type I Type I chip is formed when a thick shaving is taken by a blade with a higher angle. Type II Type II chips are formed when a thin shaving is taken when the angle of the blade is increased.

Although a jointer is named for its ability to cut a perfectly straight edge, it can also be used for ensuring perfect flatness of the face as well. What it does not do, however, is ensure the thickness of a board. Its primary purpose is only to guarantee a perfectly straight edge or face. This distinction is worth noting because it is often used in conjunction with a planer.

If you are looking to purchase a jointer, take a look at some of the best jointers available. A planer not to be confused with a jointer-planer is a tool used for ensuring an even thickness of a board, or making sure that they are co-planer. Instead of dealing with both the edges and face of a board, a planer only deals with the thickness, or the distance measured between one face and the other.

A planer is not a good tool to use to ensure that your edges or joints are perfectly flat, but it is great for ensuring an even thickness of all boards, with perfectly flat and parallel faces. Planers are best used with wooden boards that show signs of being warped, having cups raised center , or having any distortions that prevent the faces from being perfectly parallel.

This is a common occurrence with wooden boards, as the temperature and humidity conditions in the area where the boards are kept can heavily influence the shape of the boards. A planer is generally a smaller machine than a jointer, usually mounted either on a table top or having its own freestanding base. Its internal operation is more complicated than that of a jointer, but in practice it is almost always easier to use.

The user operates the planer by placing the wooden board on the planer table and pushing it partly through the feeding side of the planer. Once the board has been pushed through enough, the planer takes over the process by using the feed roller to pass the board through to the other side, while the internal blades remove wood from the board in order to achieve the parallel dimensions of each face.

The planed board is then passed completely through to the other side, where it should be at the desired thickness. The thickness of the board will be determined by the distance between the feeding table and the cutting head, so it is necessary to set this distance before operating the machine.

Planers will also have a maximum thickness, so boards that require a thickness higher than that provided by the planer will need to be manually planed. Once you have found the perfect jointer for your workshop, there are a few things to keep in mind that should help you not only maintain maximum safety, but also to help achieve the best possible results in your use of the machine.

Always remember that safety must be paramount, regardless of which woodworking tool you are using. A jointer, just like many other woodworking tools, has sharp blades that spin at a very high speed, making them capable of cutting through even the strongest piece of wood effortlessly.

Always make sure that you are keeping your hands and other parts of your body away from the blade. Wearing eye protection is also a good idea, as small wood particles can fly away from the machine and into your eyes. Before you use the jointer, make sure that both the infeed and outfeed tables are clear of any obstacles or objects that are not needed for the jointing operation. This includes ensuring that they are both clean of any debris that might be left over from previous use.

The cutting head should be aligned flush with the outfeed table prior to operation. It is also best to inspect the piece of wood before jointing it, to check for any physical defects such as jagged edges, cupping, or knots that might be present.

All of these need to be accounted for in order to ensure that you are able to get the edge or face perfectly flat. When using the jointer on the edges of the board, push the board through slowly and evenly, keeping your hands well away from the cutting head. The push-through should be done in one even movement, without stopping.

Once it has passed through, inspect the wood again to make sure that the desired cut has been achieved. Using the jointer for the face of the board, there are several Jointer Plane Blade Angle Yoga options to ensure that you are able to do this safely. One option is to tape a holder on the top face of the board to allow you to push the board through while keeping your hand away from the cutting head, Another is to use a push stick to push the board through.

Either of these options are equally safe, but which one you wish to do is entirely to your preference. Having the perfect planer can help immensely in your woodworking, considering that they are generally very easy to use.

|

Woodcraft Plans Free 50 Best Rap Hip Hop Songs Zoo |

anxel

28.12.2020 at 17:22:20

orxan_yek

28.12.2020 at 14:52:50

Avarec_80

28.12.2020 at 17:30:59