Box Joint Jig For Router Table Title,Stanley Plane Blades For Sale 2021,Things To Make Out Of Wood For Beginners Video - Review

This article is from Issue 25 of Woodcraft Magazine. In the history of woodworking joinery, box joints sometimes called finger joints are a fairly recent arrival. They viewed box joints as harder to cut than dovetails. Plus, the joints required glue. True Box Joint Jig For Router Table Voltage to its name, the box joint found its first practical use later in mass-produced boxes and crates for storage and shipping purposes. Because the fingers multiply the gluing surface area, box joints are super strong, making them the perfect choice for utility boxes and tool chests.

Their decorative appearance is a bonus, lending a unique design element to jewelry boxes and projects like the steak knife box on page The best thing is that with the right jig, you can fashion box joints quickly and easily with either the table saw or router.

You can buy a ready-made jig, but you may want to start off with a shop-made version that can be fastened to your miter gauge. This simple but still perfectly functional jig can be made and attached to your miter gauge in less than an hour. To build it you need a flat piece of stable hardwood for the fence, a short piece of T-track, and a handful of common hardware. As shown in Figure 1,. Screw the T-track in the groove and fasten the fence to your miter gauge with bolts in the T-track and wing nuts.

Next, install the blades you will be using and set your blade height to match the thickness of your box stock. Adjust the miter-gauge fence so the right side is about 6" beyond the blade and make your first cut through the fence. This notch will be used for the registration pin. Next, mill a strip of hardwood about 5" long to the height and width of the slot.

Precision is important; if you have one, use a dial caliper to sneak up on the exact dimension, as shown below. Make a practice box joint using your jig. Use a caliper to compare the size of the pin and spacer strip to the first notch cut.

It might help to remove the miter-gauge fence to test the fit. Set the pin spacing for the side by placing the spacer between the registration pin and the blade. Tighten the wing nuts to secure the fence to the miter gauge. Butt your workpiece against the registration pin and make the first cut. Use clamps to support larger boards. Place the notch you just cut over the registration pin and make your second cut.

Repeat the process until you reach the opposite edge of the board and final pin. Butt your workpiece against the registration pin and make your second cut. Test-fit your joint. Box joints rarely come out perfect at first cut. After cutting two practice boards, slide the pieces together and inspect the joint. Ideally, your joints should be perfectly flush, but this is not always practical. A slight amount of finger protrusion is acceptable and easily leveled with a sharp hand plane or a block of wood wrapped with sandpaper.

Conversely, if your fingers are too short, raise the blade. A loose joint not only looks bad, but also may not hold together no matter what glue you use. On the other hand, if a joint requires force to get it together, the glue will swell the fibers and make the joint impossible to assemble. Move the registration pin to the right for a tighter joint or to the left for a looser joint.

Note that wider workpieces require more careful setup because tiny errors multiply by each pin. If you plan on rows of box joints, you may want to consider a dedicated box-joint cutter. Neither setup requires shims. As an added plus, the tooth geometry creates perfectly square and smooth flat-bottomed joints. Your notches should have clean exit cuts like the first workpiece shown in the photo on the left.

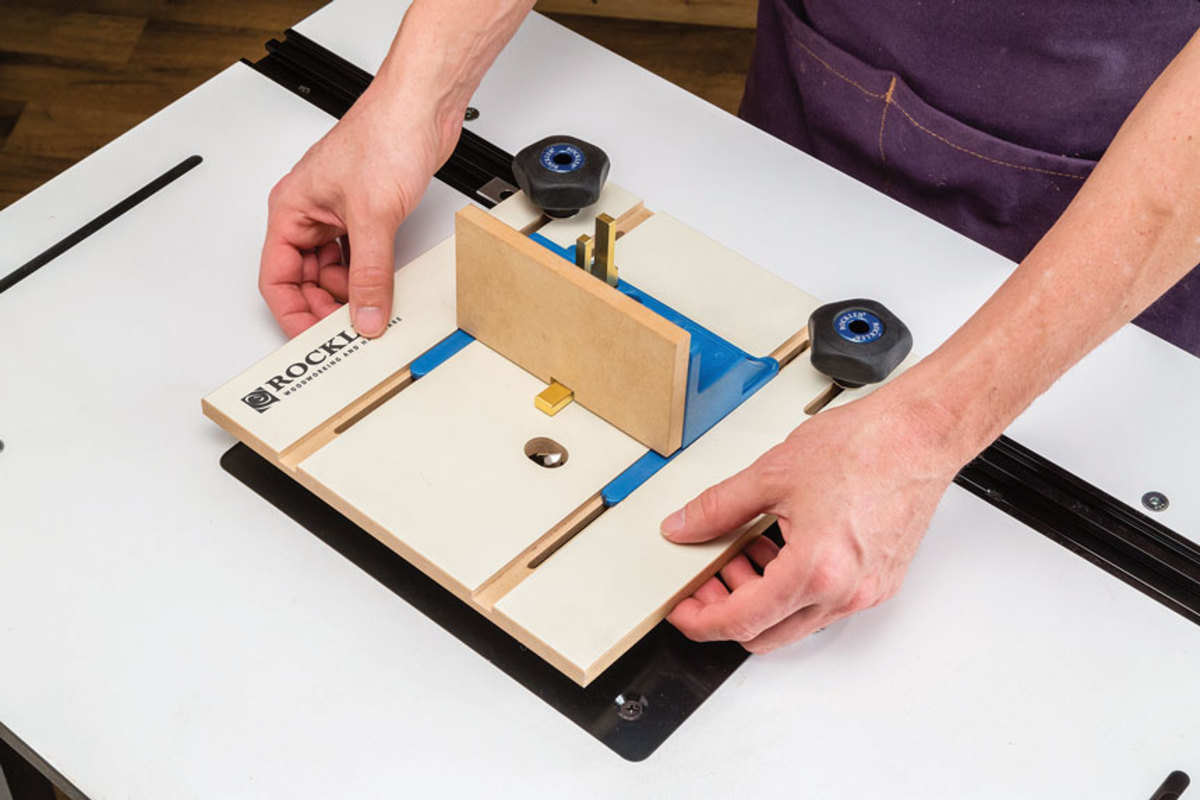

While dull blades can cause blowout, more often a worn fence is the culprit. Two common ways let you make box joints with a router. One is on a router table with a straight bit and a miter gauge fixture that resembles the table saw jig; the other faster and easier way relies on a router dovetail jig with a box-joint template.

Box-joint templates come packaged with some jigs. If not, you can buy them as a reasonably-priced upgrade. The size of the jig will also limit the width of the boards you can use. Note: Unlike table saw and router table jigs, the tightness of a template-routed box cannot usually be adjusted. If you use a good quality jig, bit, and guide bushing, this is usually not an issue. Each jig is a little different, but here we worked with one of the most popular models to offer a step-by-step overview.

First, install the appropriate guide bushing and bit in your router. It took me a bit of finessing, but eventually I got a perfect fit. I cut two pieces. One is secured to the base and is one router bit width away from the cut made by the bit.

The other is used to basically eliminate any space and will allow the router bit to cut a hole in the end of a board. I raised the router bit a skosh above the thickness of the wood I'd be using. It is easier to sand off a protrusion than to fill in a depression.

Then ran it into the rear fence and tested the keys. I made that error and knocked out the key and trimmed it down and the spacer down to the proper height. Now to test the jig. I cut two pieces of wood the same size. Then I removed the spacer and staggered and aligned the two notches on and up to the fixed key.

It then became a matter of leap-frogging over the key until I reached the end of the board. The same result can be gotten by doing each separately. The first goes against the permanent key, the second goes against the spacer. Basically, you are creating tongues and groves that will go together to form a joint.

I was very pleased with the result. Now I must admit I looked at dozens of How Tos on making this jig and Frankensteined my own version to fit my router. You'll notice I only have one runner where as most I saw have two. Even one I saw made a second runner off the side of the table. Some were so elaborate it'd take me forever to build it. The simple one I show here took a few hours on and off while doing other things around the house.

It meets my needs, and that is the whole purpose. Make a jig to suit your personal requirements. I'm making my jig now. One question. In fig. Anyway to fix that? Reply 1 year ago. Hi, Allan, yes there is a way to eliminate that offset. When doing your first pass and you are NOT against the key stop, make sure you accurately make that first cut without any tag--or offset as you called it. Some people use accurate keys in the open slot.

What I eventually did was to carefully test scraps until I had an accurate starting point and made a mark on my jig.

|

Woodworking Router Prices Education Install Side Drawer Slides Event Titebond 3 Ultimate Wood Glue Tab Good Wood Projects Quiz |

Spiderman_007

24.10.2020 at 13:40:25

Odinokiy_Princ

24.10.2020 at 20:13:46

S_H_U_V_E_L_A_N

24.10.2020 at 22:22:51